9400 highline | parameter setting & configuration – Lenze E94AxHE Servo Drives 9400 HighLine (Firmware 01-37) User Manual

Page 295

L

Firmware 1.37 - 09/2006

295

9400 HighLine | Parameter setting & configuration

TAs for interconnection via electrical shaft

Introduction | Application examples

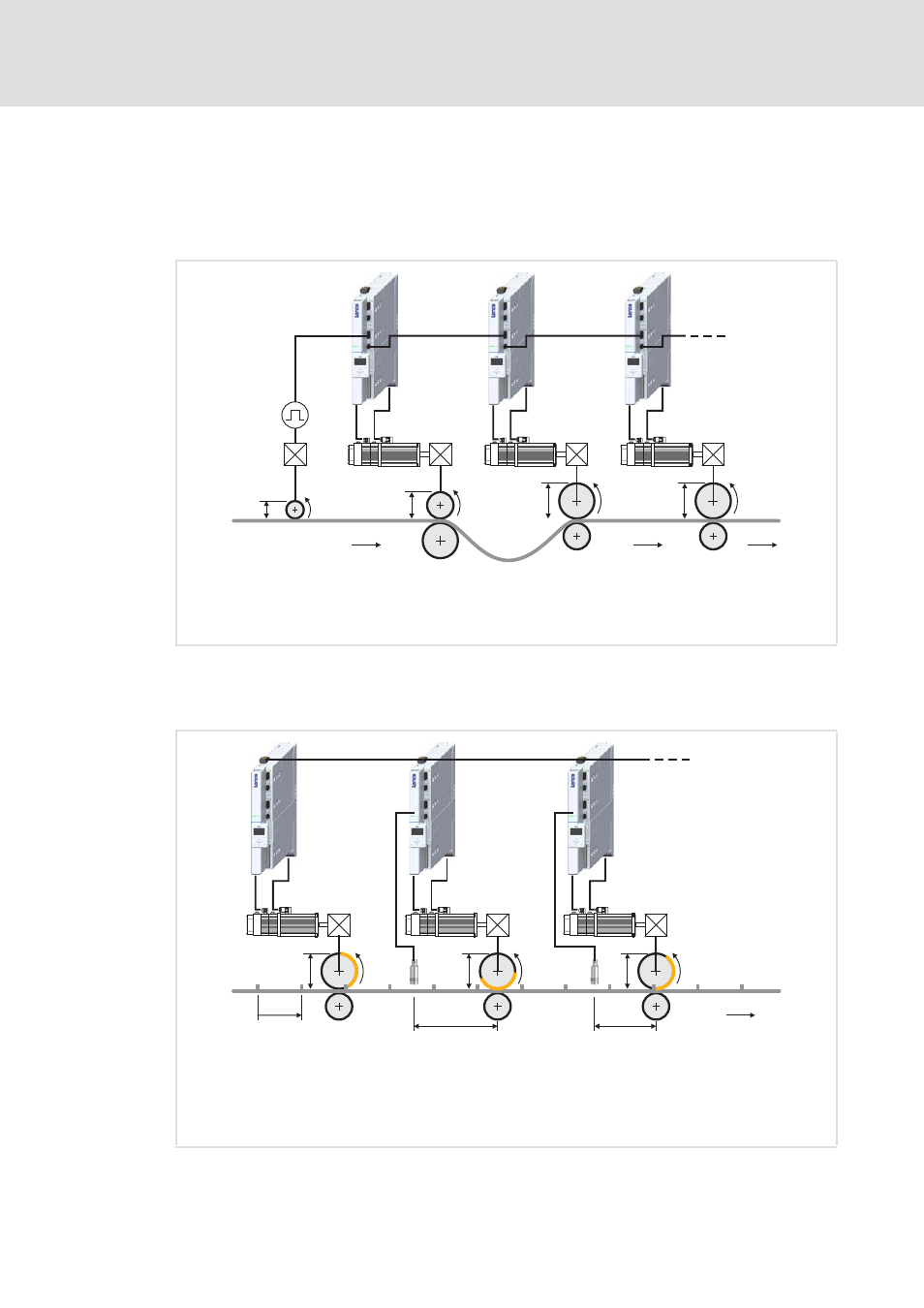

Tighten the web via trimming function with cascade

In case a clearance has developed, the web must be "tightened" again. Only then the

machine can be accelerated again via the master. The subsequent slave (cascade structure)

must run along in the set ratio. Thus, the trimming function acts directly before or after the

stretching factor.

[12-6] Trimming function in case of the electronic gearbox as cascade

Relative synchronism with mark synchronisation and virtual master

[12-7] Relative synchronism with virtual master (rail)

n

Real master/slave 1

o

Slave 2 with master value trimming

p

Slave 3

q

Digital frequency cascade (digital frequency extension module required)

i

Slave

Master/Slave

d

v

d

v

d

v

R1

R2

R4

1

2

4

i

1

i

2

4

v

3

v

4

i

Slave

d

v

R3

3

3

v

1

Digital

frequency

n

Virtual master (and slave 1)

o

Slave 2

p

Slave 3

q

Electrical shaft, implemented here via system bus (CAN).

r

Register (cycle of guiding angle/guiding angle)

s

Sensor for mark synchronisation

i

Slave

Master/Slave

d

v

R3

3

i

1

3

System bus

v

i

Slave

d

v

R2

2

2

d

v

R1

1

a

2

a

3