9400 highline | parameter setting & configuration – Lenze E94AxHE Servo Drives 9400 HighLine (Firmware 01-37) User Manual

Page 296

9400 HighLine | Parameter setting & configuration

TAs for interconnection via electrical shaft

Introduction | Application examples

296

Firmware 1.37 - 09/2006

L

In case of the relative synchronism with mark synchronisation, there is a position reference

between tool and web, which occurs in each register. For this, a slight correction is

superimposed to the synchronous motion with regard to the web. Such applications are,

for instance, printing machines.

For the mark synchronisation in particular the register r (the cycle of the guiding angle)

and the distance of the sensor s from the home position of the tool (distances a

2

and a

3

)

are relevant.

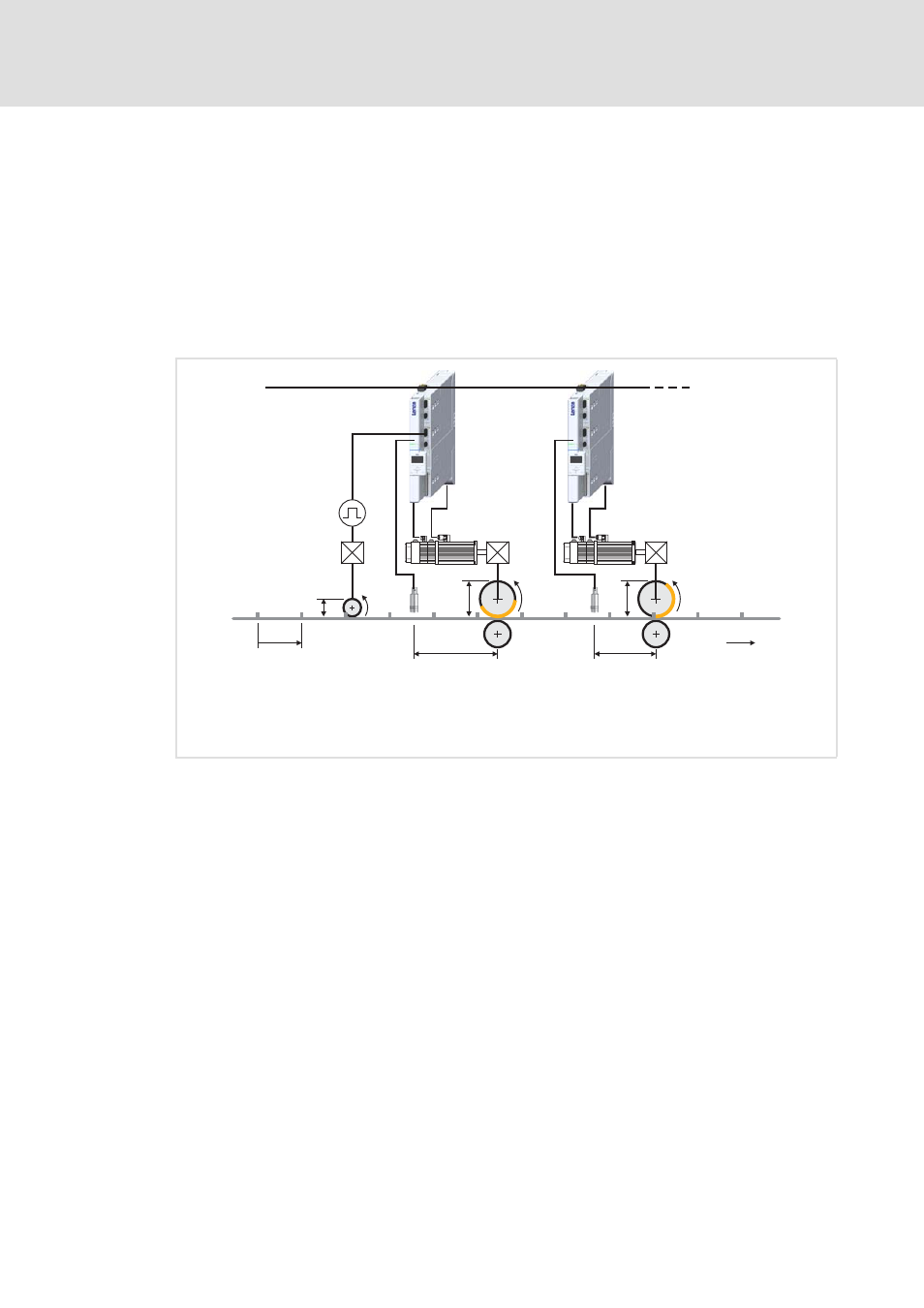

Relative synchronism with mark synchronisation and real master

[12-8] Relative synchronism with real master (track)

n

Real master/slave 1 (digital frequency extension module required)

o

Slave 2

p

Electrical shaft, implemented here via system bus (CAN).

q

Register (cycle of guiding angle/guiding angle)

r

Sensor for mark synchronisation

i

Slave

d

v

d

v

R1

R3

1

3

i

1

3

System bus

v

i

Master/Slave

d

v

R2

2

2

a

2

a

3