3 system with motor encoder and position encoder, 9400 highline | parameter setting & configuration – Lenze E94AxHE Servo Drives 9400 HighLine (Firmware 01-37) User Manual

Page 113

L

Firmware 1.37 - 09/2006

113

9400 HighLine | Parameter setting & configuration

Encoder evaluation

Parameter setting

6.2.3

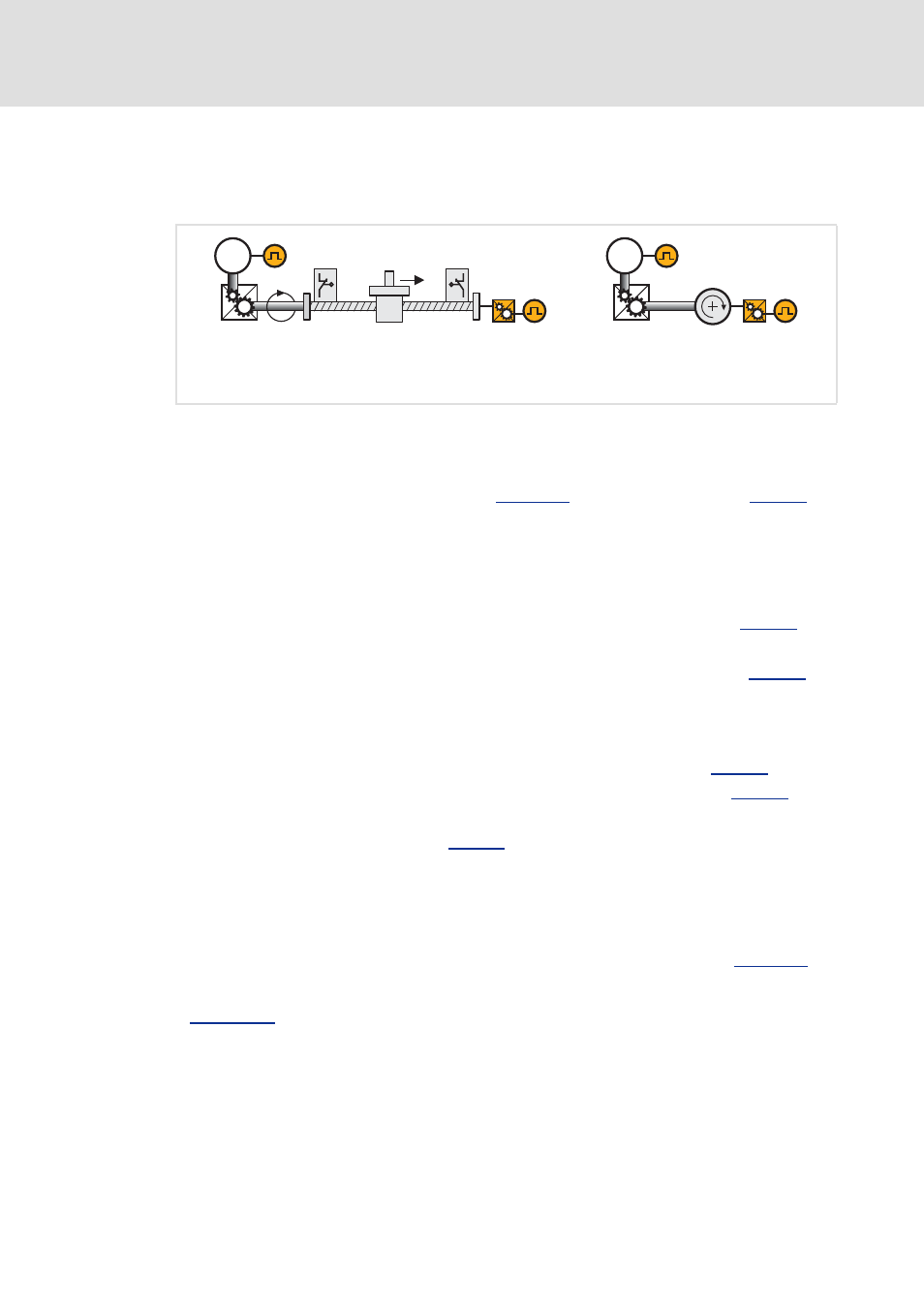

System with motor encoder and position encoder

The optional position encoder is used as feedback for the position control and transmits

the position of slide or drive roll to the controller.

[6-3]

Schematic diagram - feedback with separate position encoder

In this case, the actual position and speed values on the machine side result from

converting the position encoder position via the resulting gearbox factor (ratio of motor

speed to position encoder speed; display in

M

How to activate the use of a separate position encoder:

On the Application parameter

tab in the dialog level Overview Drive interface Machine parameter:

1. Select the "position control" in the Controller configuration list field (

) in

order that the position encoder will be evaluated.

2. Select the position encoder available in the Position encoder list field (

3. Select the gearbox ratio of the position encoder (ratio of load speed to encoder

speed) as a quotient (numerator/denominator) which results from the resulting

teeth number:

• Enter numerator in the input field Gearbox fact. numer. load (

).

• Enter denominator in the input field Gearbox fact. denom. load (

4. If required, adapt the position encoder mounting direction via the list field Position

encoder mounting direction (

). The position encoder mounting direction is

preset to "Encoder rotating CW".

O

Tip!

The resulting gearbox factor for the position encoder is displayed in

.

See also:

n

Motor encoder

o

Position encoder

p

Gearbox ratio for position encoder

M

M