6 noise prevention and the installation – IAI America XSEL-S User Manual

Page 73

Chapter 1 Specifications Check

1.6 Noise Prevention and the Installation

65

1.6 Noise Prevention and the Installation

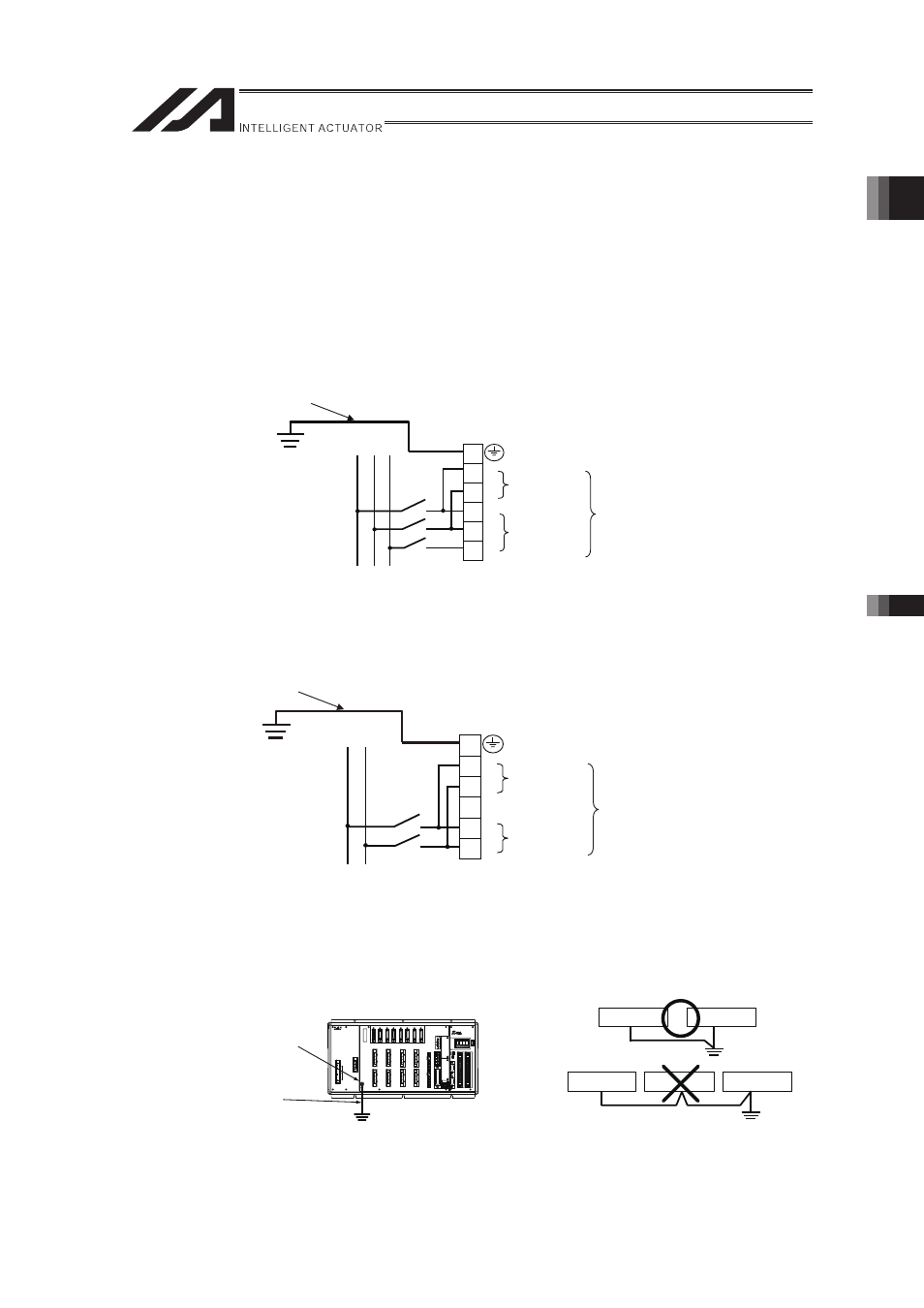

(1) Protective Ground

For the grounding, the grounding resistance should be set to 100� or less.

The wiring should apply a twist line or an annealed copper wire of 2.0 mm

2

(AWG14) or more.

Apply 3.5mm2 or more for XSEL-SX-NNN10040 and 12040.

[3-Phase Type]

L

N

R

S

T

1

L 2

L 3

L

For Motor

Driving

AC Power Supply

Input Connector

Grounding resistance

at 100Ω or less

For Control

AC Power Supply Input

Strand or annealed copper wire:

Connect with an earth line of

2.0mm

2

(AWGN) or more

Apply 3.5mm2 or more for

XSEL-SX-NNN10040 and 12040.

�

�

�

[Single-Phase Type]

�

L

N

L

N

L N

For Motor

Driving

AC Power Supply

Input Connector

Grounding resistance

at 100Ω or less

For Control

AC Power Supply Input

Strand or annealed copper wire:

Connect with an earth line of

2.0mm

2

(AWGN) or more

�

�

�

(2) Noise Elimination Grounding (Frame Ground)

For grounding, make sure to conduct Class D Grounding (grounding resistance 100� or less).

Apply annealed twist wire or copper wire cables with 2.0 mm

2

(AWG14) or more for wiring and

connect with solderless ring tongue terminals.

�

�

Controller

Controller

Other Equipment

Other Equipment

Other Equipment

Do not share the ground wire with or connect to other equipment.

Ground each controller separately.

Grounding resistance at 100Ω or less

Attach the grounding

cable to the FG terminal

on the main machine.

Strand or annealed copper wire:

Connect with an earth line of

2.0mm

2

(AWGN) or more

Apply 3.5mm2 or more for

XSEL-SX-NNN10040 and

12040.