IAI America XSEL-S User Manual

Page 48

Chapter 1 Specifications Check

1.2.1 XSEL-R/S Controller

Type

40

[Calculation Example]

Shown below is an example for how to calculate the power capacity and amount of heat

generation when the following actuators are used.

Axis 1 Actuator 200W�

Axis 2 Actuator 200W�

Axis 3 Actuator 100W�w/ brake� Axis 4 Actuator 60W�

Standard type Controller�Option: PIO Board 1 sheet,, Device Net

Teaching Pendant (IAI Standard Type)�

�

�

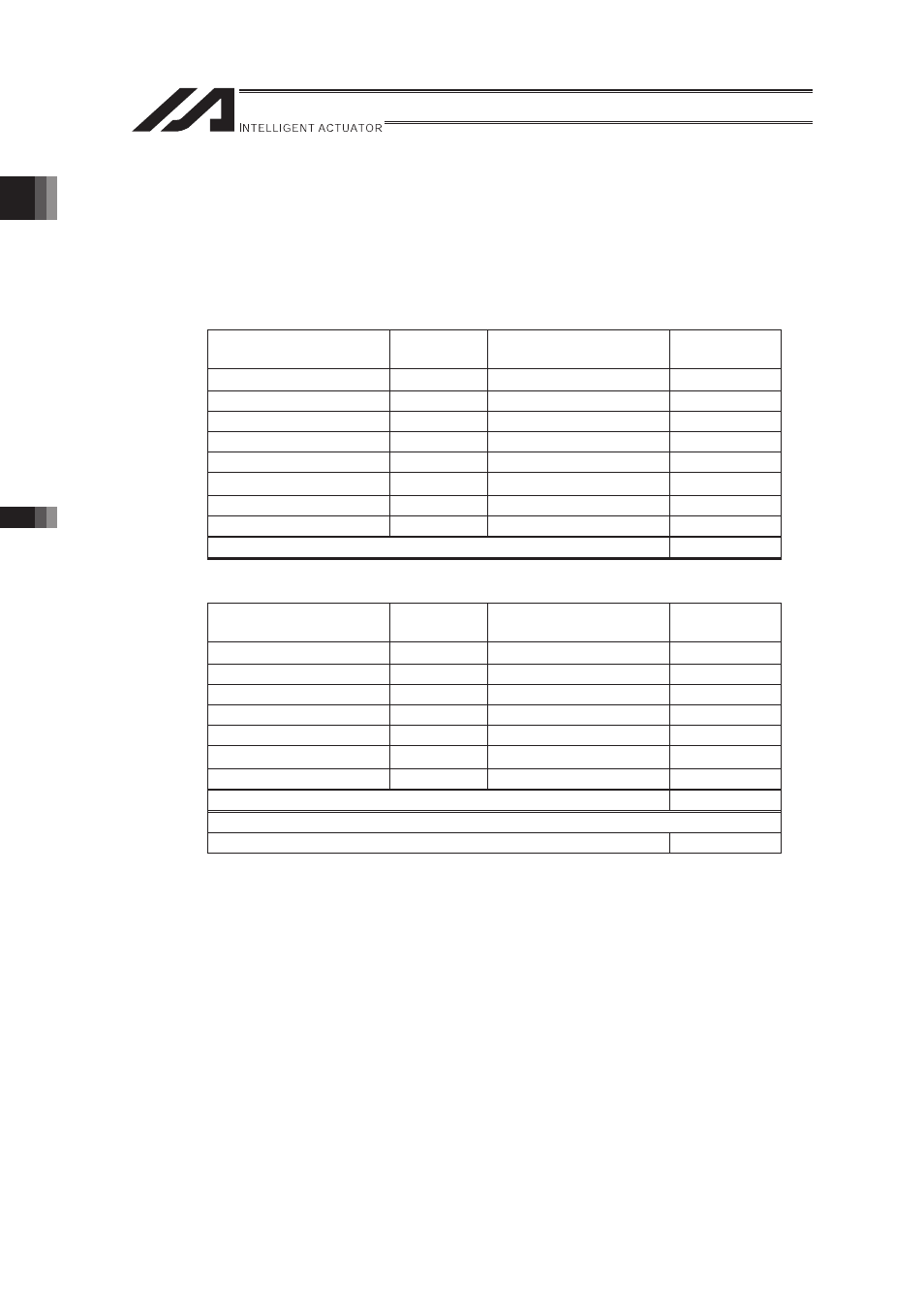

1) Control Power Capacity�

Base Unit

Quantity

Power consumption

(Per Unit)

Total [VA]

Base Unit

�

31.4

31.4

Driver

2

6.26

12.52

Encoder

4

2.38 + 3.57

23.8

Fan Unit

6

5.71

34.26

PIO Board

1

5.95

5.95

Device Net

�

1.98

1.98

Teaching pendant

1

3.57

3.57

Brake

1

0.14

0.14

Totalizer

113.62

2) Heat Generation of Control System

Base Unit

Quantity

Power consumption

(Per Unit)

Total [VA]

Base Unit

�

31.4

31.4

Driver

2

6.26

12.52

Encoder

4

2.38

9.52

Fan Unit

6

5.71

34.26

PIO Board

1

5.95 + 14.52

20.47

Device Net

�

1.98 + 3.43

5.41

Brake

1

2.64

2.64

Totalizer

116.22

Heat Generation [W] = Totalizer [VA] × 0.7(Efficiency)×0.6(Power Factor)

48.81

�

3) I/O (PIO Board Board ) Power Capacity (24V DC)�

14.52 × 1 = 14.52 [VA]

�

4) Brake Power Capacity (24V DC)

(2.5 + 5.8) ×1 = 8.3 [VA]

5) Motor Power Capacity

421 + 421 + 234 + 138 = 1214 [VA]

6) Motor Power Supply Heat Generation

9.12 + 9.12 + 6.12 + 3.39 = 27.75 [W]

�

7) Rated Power Capacity =

1) Control Power Capacity + 5) Motor Power Capacity = 113.62 + 1214 = 1327.62 [VA]

8) Heat Generation =

2) Heat Generation of Control System + 6) Motor Power Supply Heat Generation = 48.81

+ 27.75 = 76.56 [W]