IAI America XSEL-S User Manual

Page 355

Chapter 6 Parameter

6.3.1 For XSEL-R/S

347

Axis-Specific Parameters (XSEL-R/S)

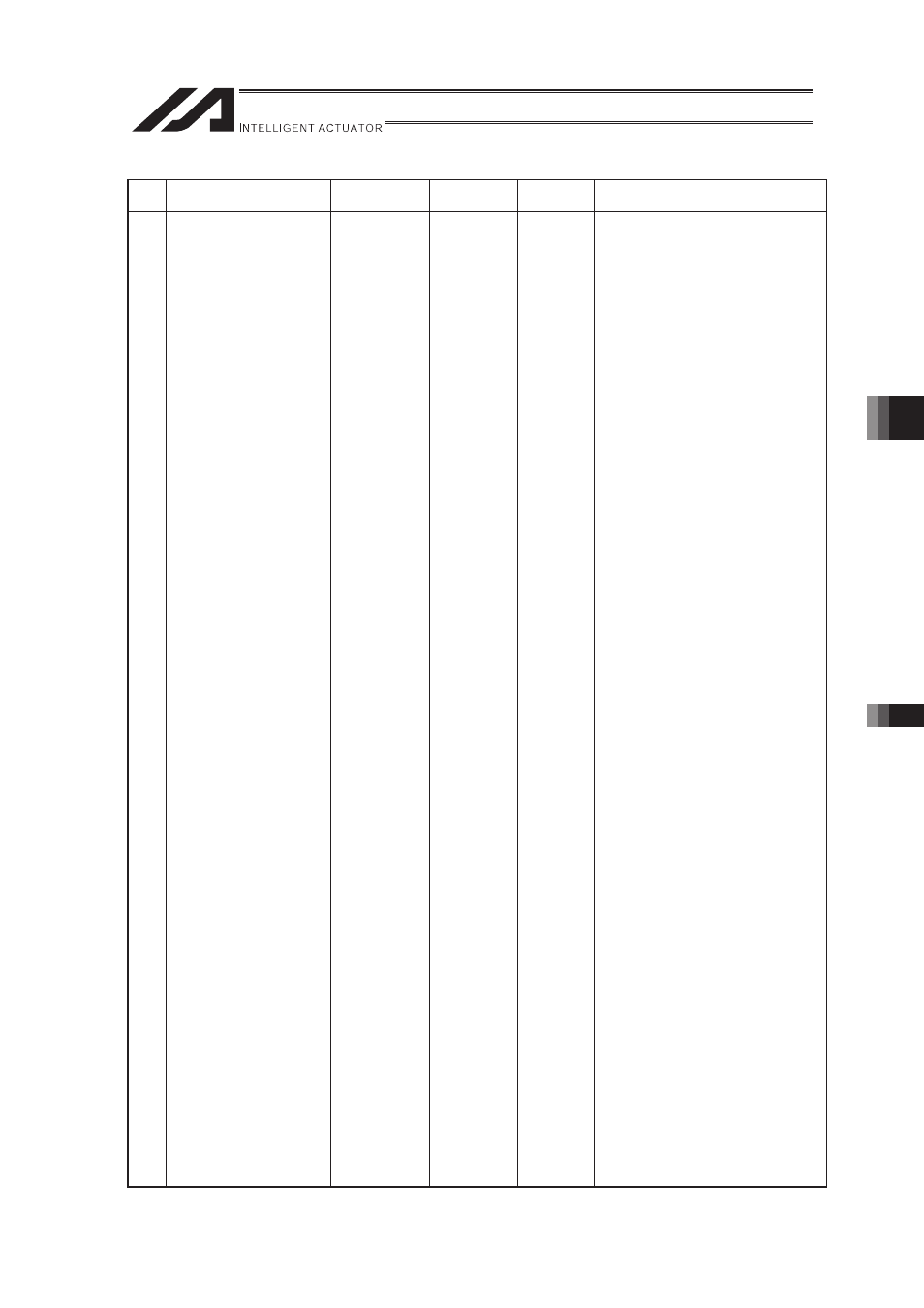

No.

Parameter name

Default value

(reference)

Input range

Unit

Remarks

52 Synchronizing Setting Bit

Pattern 1

0

0H to

FFFFFFFFH

Bits 0 to 3: Select synchro-slave axis

position loop encoder

pulse input

(0: Slave axis encoder pulse input

(normally)

1: Main axis encoder pulse input)

*Valid only for synchro-slave axes

Bits 4 to 7: Synchronizing control type

(0: Double sensor control (normally)

* Set to 0 for normal synchronizing.

Select 2, 3 or 1 considering the

situation only when there is no

freedom in “independent” control in

the same coordinate for the master

axis and slave axes.

* Setting is also necessary in Each

Axis Parameters No. 69, 77 and 58.

(Example for Setting (Master/Slave

Axes)):

No.69 Restriction in torque for

synchro-slave axis stop = 0/0%

No.77 Synchro S pulse = 3/3 pulse

No.58 positioning width =

100/100�m)

1: Double sensor control (slave axis 1

ingredient cancelled when moving)

* Establish the setting considering

the situation only when there is no

freedom in “independent” control in

the same coordinate for the master

axis and slave axes.

(Setting available only for horizontal

axes)

* There is a tendency that the load

on the master axis is big even in

constant condition because the

slave axes are more like a

supportive drive.

* Setting is also necessary in Each

Axis Parameters No. 69, 77 58 and

108.

(Example for Setting (Master/Slave

Axes)):

No.69 Restriction in torque for

synchro-slave axis stop = 0/50%

No.77 Synchro S pulse = 3/

[calculated value (converted in

300�m)]

No.58 positioning width =

100/300�m

No.108 Control switchover width in

synchro-slave axis positioning =

0/5000�m)

2: Single sensor control

* Establish the setting considering

the situation only when there is no

freedom in “independent” control in

the same coordinate for the master

axis and slave axes.

* Setting is also necessary in Each

Axis Parameters No. 69, 77 and 58.

(Example for Setting (Master/Slave

Axes)):

No.69 Restriction in torque for

synchro-slave axis stop = 0/0%

No.77 Synchro S pulse = 3/3 pulse

No.58 positioning width =

100/300�m)