1 parameter setting, 11 basic drive functions, Stop – Lenze 9400 User Manual

Page 408

11

Basic drive functions

11.5

Manual job, encoderless

408

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

• Support for

in the case of torque and linear motors by means

of

• movement to a machine position in which pole position identification can be carried out in a

reproducible manner and

• setting of the pole position angle with the "PL touch probe signal"

11.5.1

Parameter setting

• Parameterising dialog box in»Engineer«: Tab Application parameters Dialog level Overview

All basic functions Manual jog (OL)

• Short overview of the parameters for manual jog, encoderless:

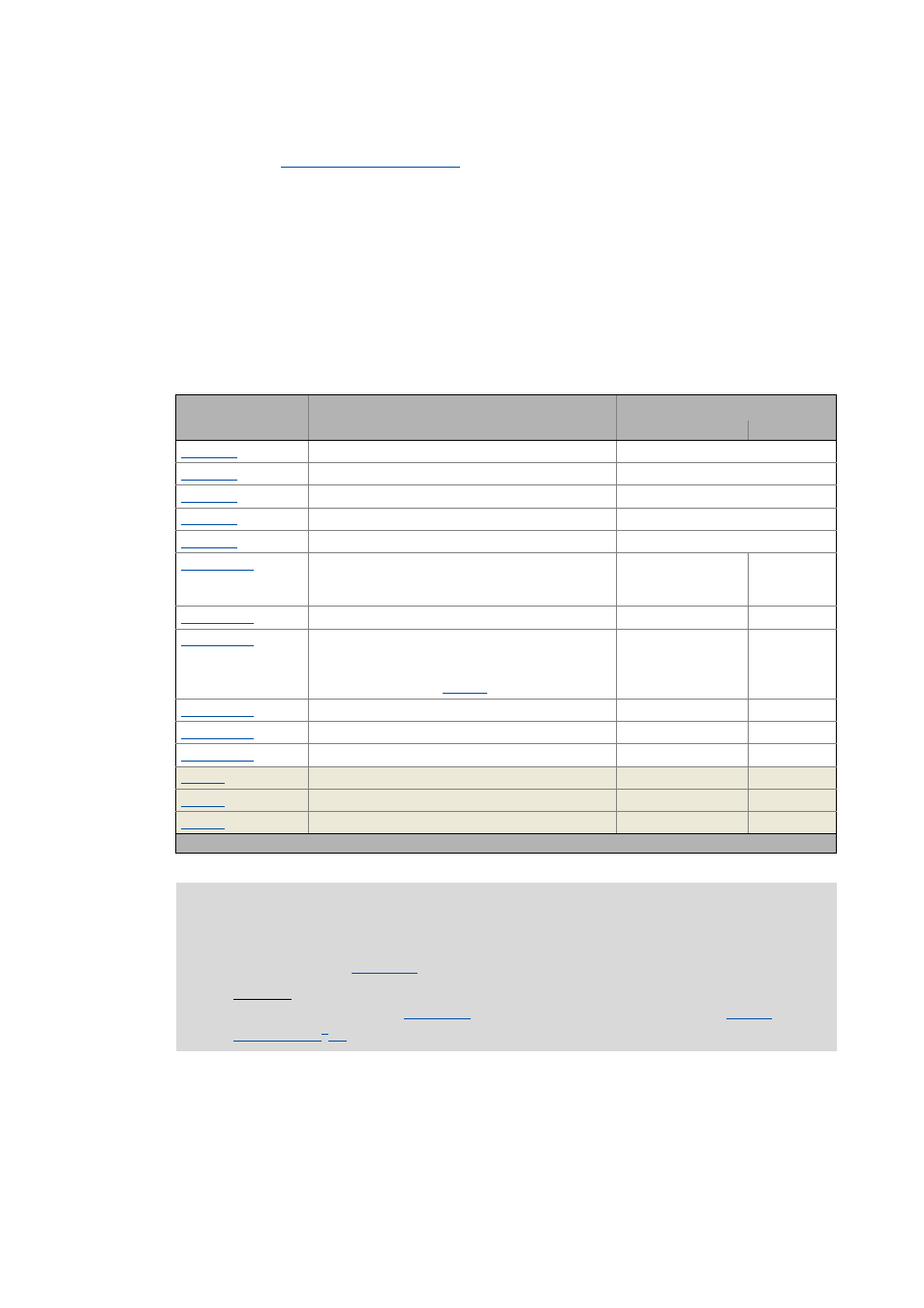

Parameter

Info

Lenze setting

Value Unit

EnableManualMode

0: Deactivate

JogPositive

0: Deactivate

JogNegative

0: Deactivate

ActivateDataBit1

0: Deactivate

ActivateDataBit2

0: Deactivate

Frequency

• Field frequency f

d

with which the current vector

rotates.

1.0 Hz

Start angle

0.0 °

Current

• R.m.s. value of the current vector which is injected

with the parameterised frequency/starting angle.

• 100 % ≡ I

max_device

10.00 %

Acceleration time

1.000 s

Deceleration time

1.000 s

Max. activation time

1.000 s

Mol_SetpointCurrent

- A

Mol_dnState

-

ManualJogOpenLoop: Dig. signals

-

Greyed out = display parameter

Stop!

At the frequency f

d

= 0 Hz, the r.m.s. value increases to 141 % of the current

parameterised in

. As a result, the connected motor can be destroyed!

Remedy: Activation of a derating curve in i2xt monitoring or limitation of the

parameterised current in

to 71 % of the rated motor current.