2 gearbox ratio, Gearbox ratio, 4drive interface – Lenze 9400 User Manual

Page 31

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06

31

4

Drive interface

4.1

Machine parameters

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.1.2

Gearbox ratio

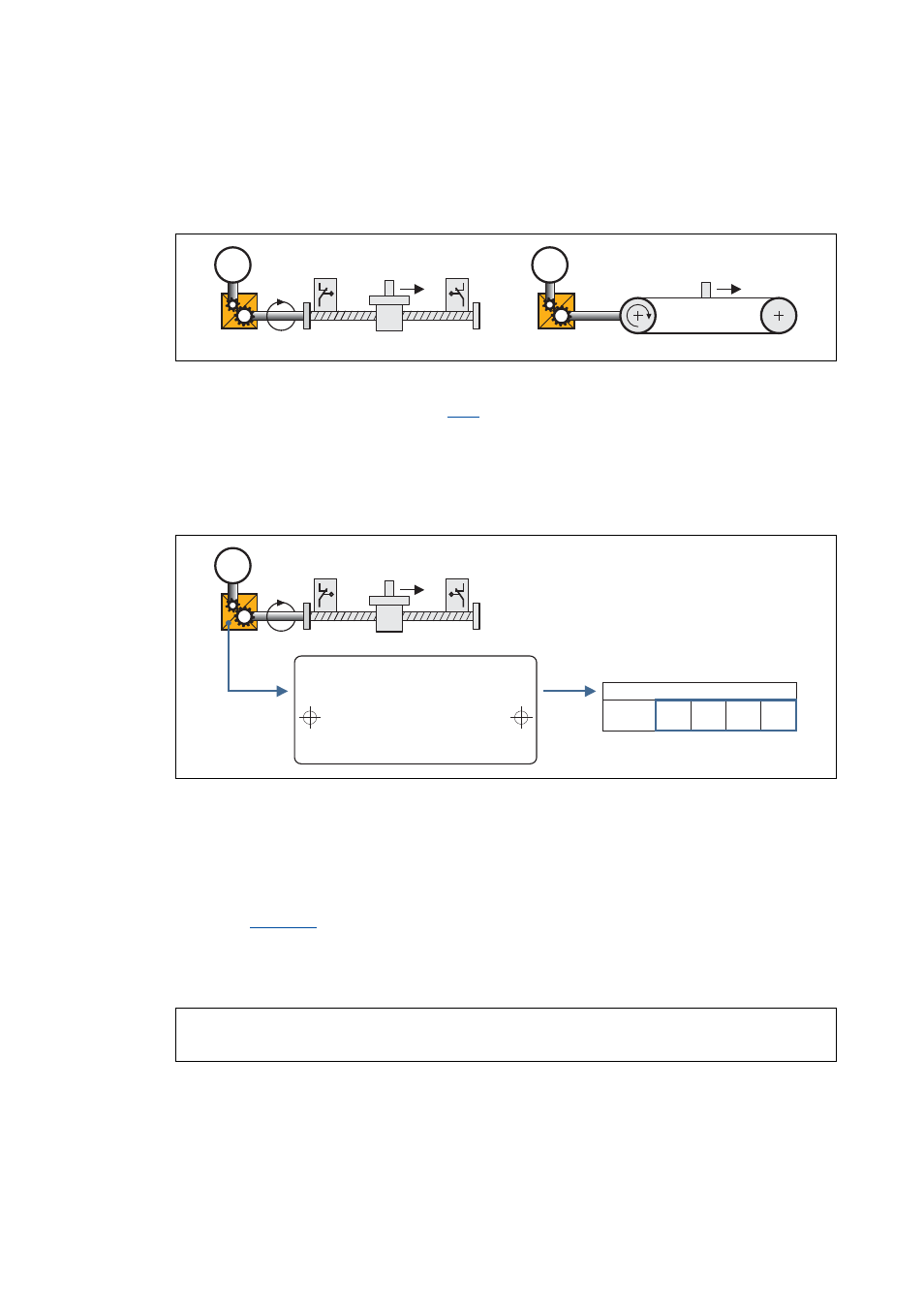

The gearbox ratio indicates the number of revolutions of the motor axis it takes for exactly one

revolution of the load axis (e.g. spindle or drive roll) to take place.

[4-1]

Schematic diagram of gearbox ratio

• In the example shown in illustration

one revolution of the spindle is carried out at exactly

58,667 revolutions of the motor axis.

Specification of the gearbox ratio

• The gearbox ratio is to be defined in the form of a quotient (numerator/denominator); the data

required can be found in the technical data for the gearbox:

[4-2]

Example: Technical data relating to the gearbox (from gearbox catalogue)

Tip!

In order to specify the gearbox ratio exactly, use the number of teeth indicated on the data

sheet or in the catalogue, if possible, instead of the information on the nameplate (see

following calculation).

In

the gearbox factor is displayed in decimal format.

Example calculation on the basis of the technical gearbox data:

[4-3]

Calculation example

M

M

i = 58.667

L

EXTERTAL / Germany

GFL05-2M HCR 080-32

004 B

295 Nm

24/min (50Hz)

i = 58.667

GT/40000027

CLP 460

1196

00500038

GFL 05

i

58.667

z3

9

z1

12

z2

88

z4

72

M

Gearbox factor numerator (C02520)

z2 z4

Ч

88 72

Ч

=

=

6336

=

Gearbox factor denominator (C02521)

z1 z3

Ч

12 9

Ч

=

=

108

=