5motor interface – Lenze 9400 User Manual

Page 220

5

Motor interface

5.9

Monitoring

220

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.9.2.3

UL 508-compliant I²xt motor temperature monitoring

The following test steps 1 ... 4 are part of the UL 508C-compliant device acceptance.

They have to be executed successfully during the I²xt motor monitoring.

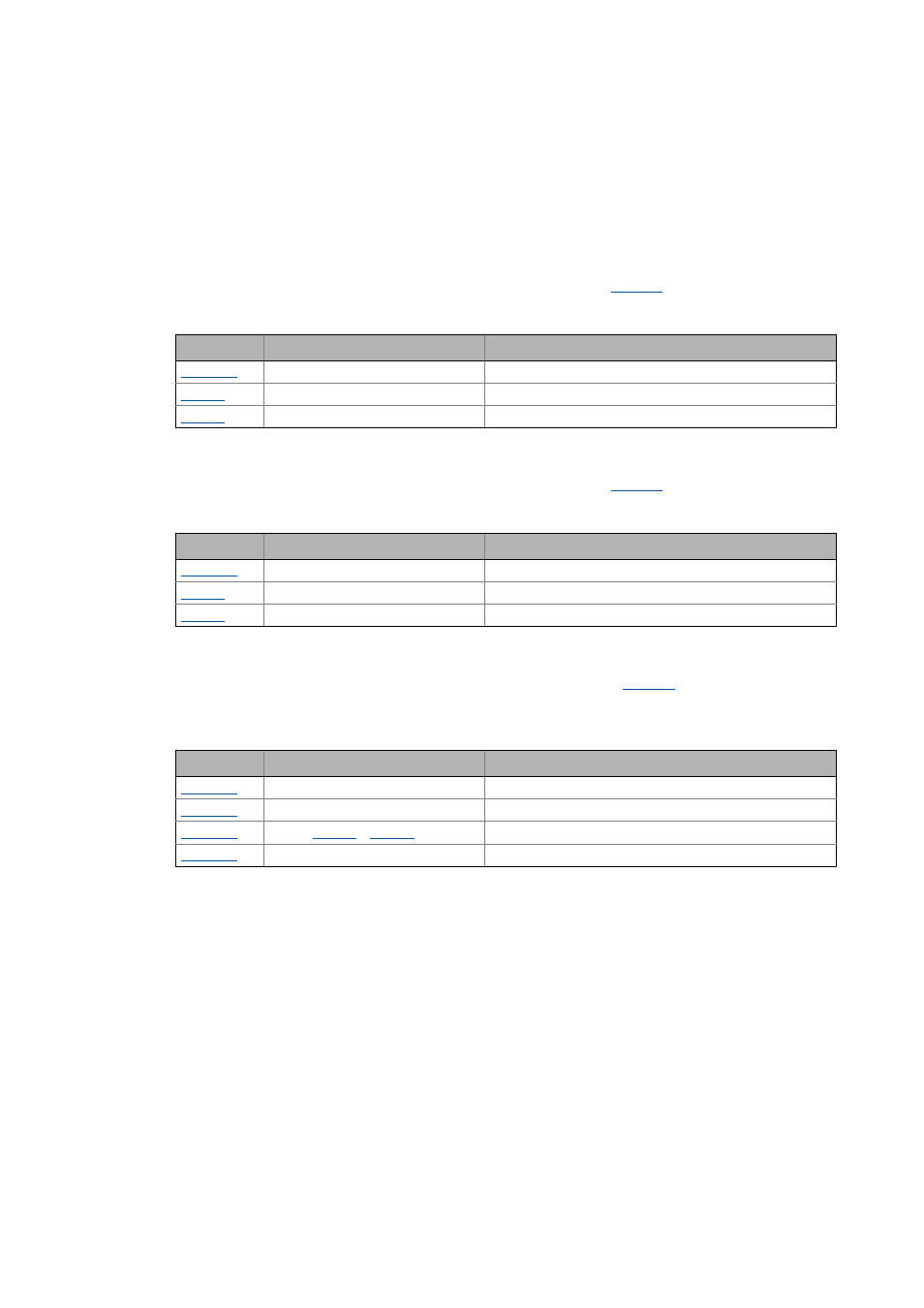

Test step 1

• Motor overload: 6 x I

rated,mot

(I

rated,mot

: Rated motor current (

))

• Trigger time: Max. 20 s after the overload has occurred

Test step 2

• Motor overload: 2 x I

rated,mot

(I

rated,mot

: Rated motor current (

))

• Trigger time: Max. 480 s after the overload has occurred

Test step 3

• Motor overload: 1,1 x I

rated,mot

(I

rated,mot

: Rated motor current (

• In case of a motor field frequency of 10 Hz, the I²xt motor monitoring has to be tripped faster

than with a motor field frequency of 20 Hz.

Code

Setting

Info

11.8 min

Thermal time constant - laminated core/housing

0 %

Percentage of the winding in the final temperature

100 %

Switch-off threshold of motor overload protection (I²xt)

Code

Setting

Info

27.8 min

Thermal time constant - laminated core/housing

0 %

Percentage of the winding in the final temperature

100 %

Switch-off threshold of motor overload protection (I²xt)

Code

Setting

Info

0 %

Speed = 0 (standstill)

< 100 %

Permissible motor torque at standstill

20 Hz /

Speed n

2

from which on the torque must be reduced

100 %

Permissible motor torque at speed n

2

(torque reduction)