7 setting the s-ramp time, Setting the s-ramp time, 11 basic drive functions – Lenze 9400 User Manual

Page 382: Stop

11

Basic drive functions

11.1

General information

382

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

11.1.7

Setting the S-ramp time

For path planning, various basic functions serve to build up or reduce the acceleration linearly. The

motion profile causes less structural vibrations and the gearboxes are protected.

The smoothening (jerk) is calculated via the S-ramp time and the maximum acceleration permitted

in the profile:

[11-3] Formula for calculating the jerk for acceleration and deceleration phases

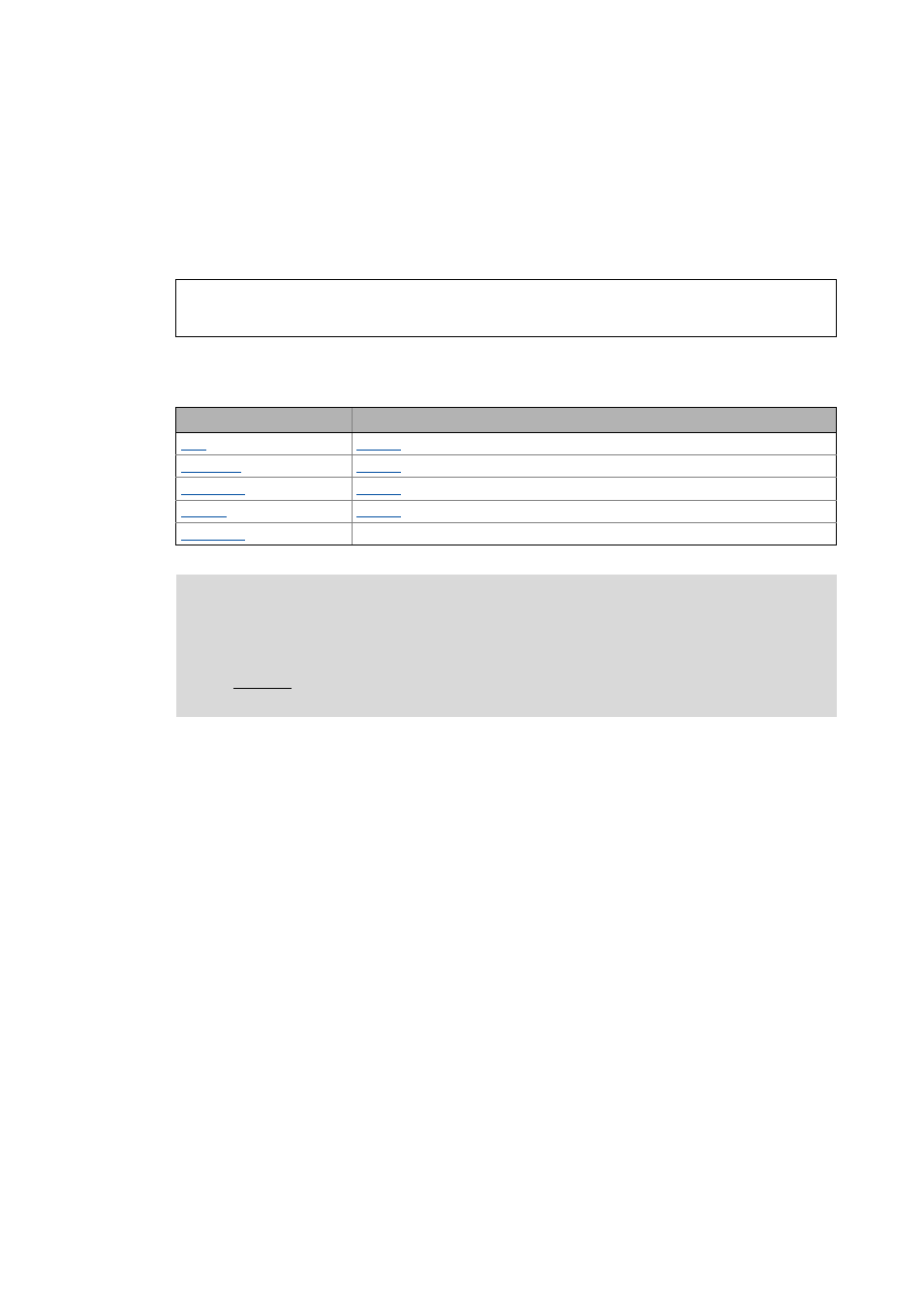

S-ramp times can be set in the given parameters for the following basic functions:

Jerk

maximum acceleration

S-ramp time

------------------------------------------------------------

=

Basic function

Parameter for S-ramp time

The S-ramp time is defined via FB L_PosPositionerTable or FB L_PosProfileTable.

Stop!

When it is switched to another basic function, the start acceleration is reduced with the

jerk of the new basic function. A small jerk causes very high speeds!

Remedy: Avoid unnecessarily long S-ramp times. Set the profile parameters of the

different basic functions so that the jerk is roughly the same for all basic functions.