3 limits of motor phase failure monitoring, 5motor interface – Lenze 9400 User Manual

Page 229

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06

229

5

Motor interface

5.9

Monitoring

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.9.4.3

Limits of motor phase failure monitoring

Motor phase failure monitoring can be activated for both synchronous and asynchronous motors.

However, it is possible that a current flow cannot be detected for sure in the case of certain

operating statuses of correctly connected synchronous motors. Hence, a fault is triggered.

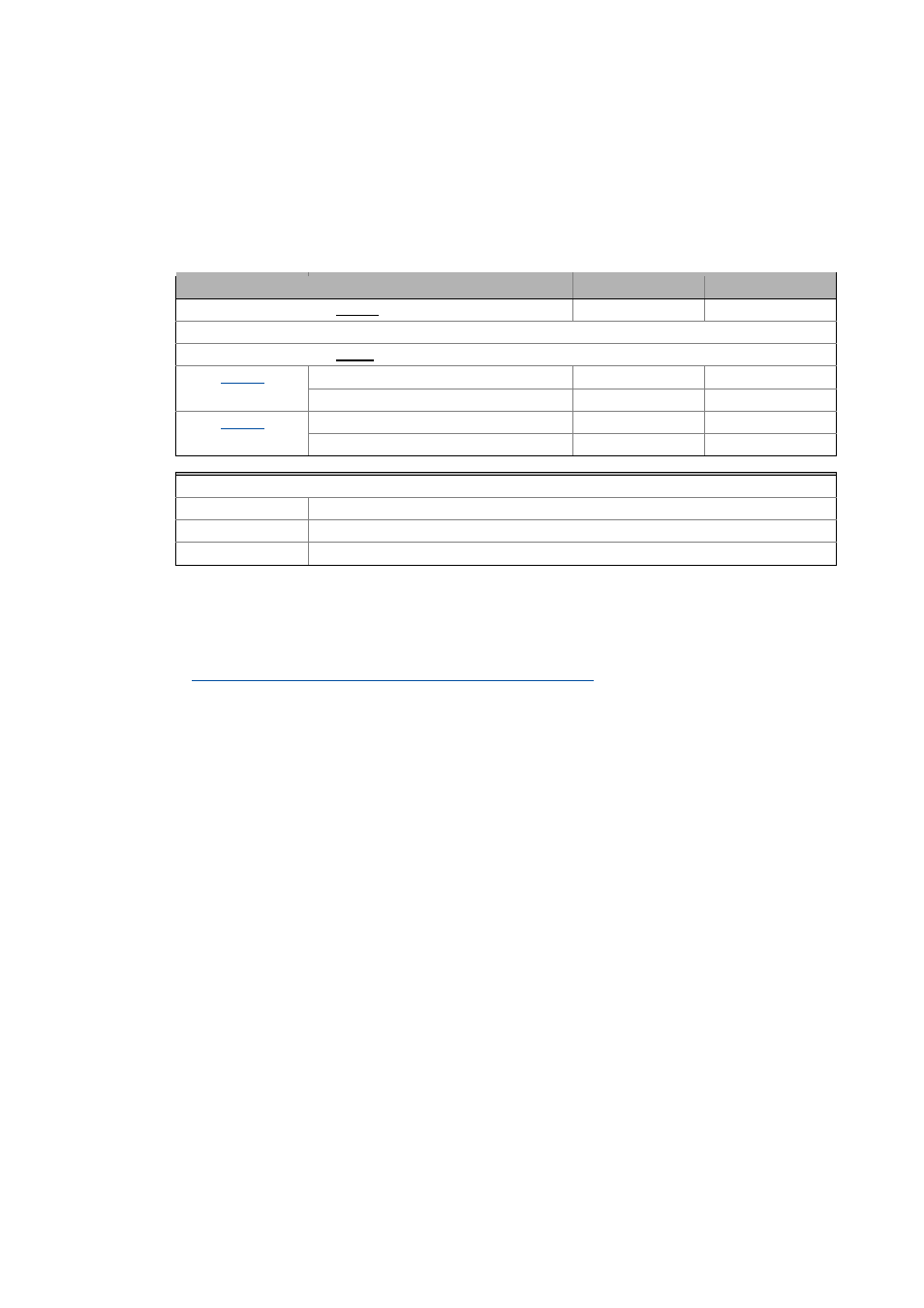

The following table provides an overview:

Special case: Hoist

The special case "Hoist" is already referred to in the chapter

Monitoring of the individual motor phases during operation

Motor phase failure monitoring may trigger a fault message in a hoist if the applied asynchronous

motor reaches the following working point:

• The hoist moves downwards, i.e. the motor is in generator mode.

• The slip frequency equals the field frequency in terms of amount. Both frequencies mutually

neutralise themselves due to their opposite effective directions.

Operating status

Synchronous motor

Async. motor

Check of the motor phases prior to operation

ž

ž

Check of the motor phases during operation

• I

q

<

at standstill

when motor is rotating

• I

q

≥

at standstill

when motor is rotating

Explanation

Phase failure is detected for sure.

Phase failure detection may trip without a fault pending.

I

q

Torque-forming current component