5 determining the motor parameters, Determining the motor parameters, Determining the motor – Lenze 9400 User Manual

Page 138: Parameters, 5motor interface, Danger

5

Motor interface

5.3

Adjusting motor and controller to each other

138

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.3.5

Determining the motor parameters

To control an electrical machine, the motor parameters must be known.

• The motor parameters for Lenze motors are known and are already set accordingly by selecting

them from the »Engineer« motor catalogue or reading out the ENP.

• The device command "Determine motor parameters" is used to automatically determine the

motor parameters for a third-party motor that are listed in the following table – if they are not

known:

Requirements

• For the automatic determination of the motor parameters it is required that first the switching

performance of the inverter has been optimised successfully, to ensure that the current has a

sinusoidal form.

Optimising the switching performance of the inverter

Note!

Only required for servo control if the motor parameters are to be defined by a motor

from a third-party manufacturer!

Always required for sensorless vector control!

• An optimum drive performance can only be achieved with the sensorless vector

control if the motor parameters correspond to the real motor as exactly as possible.

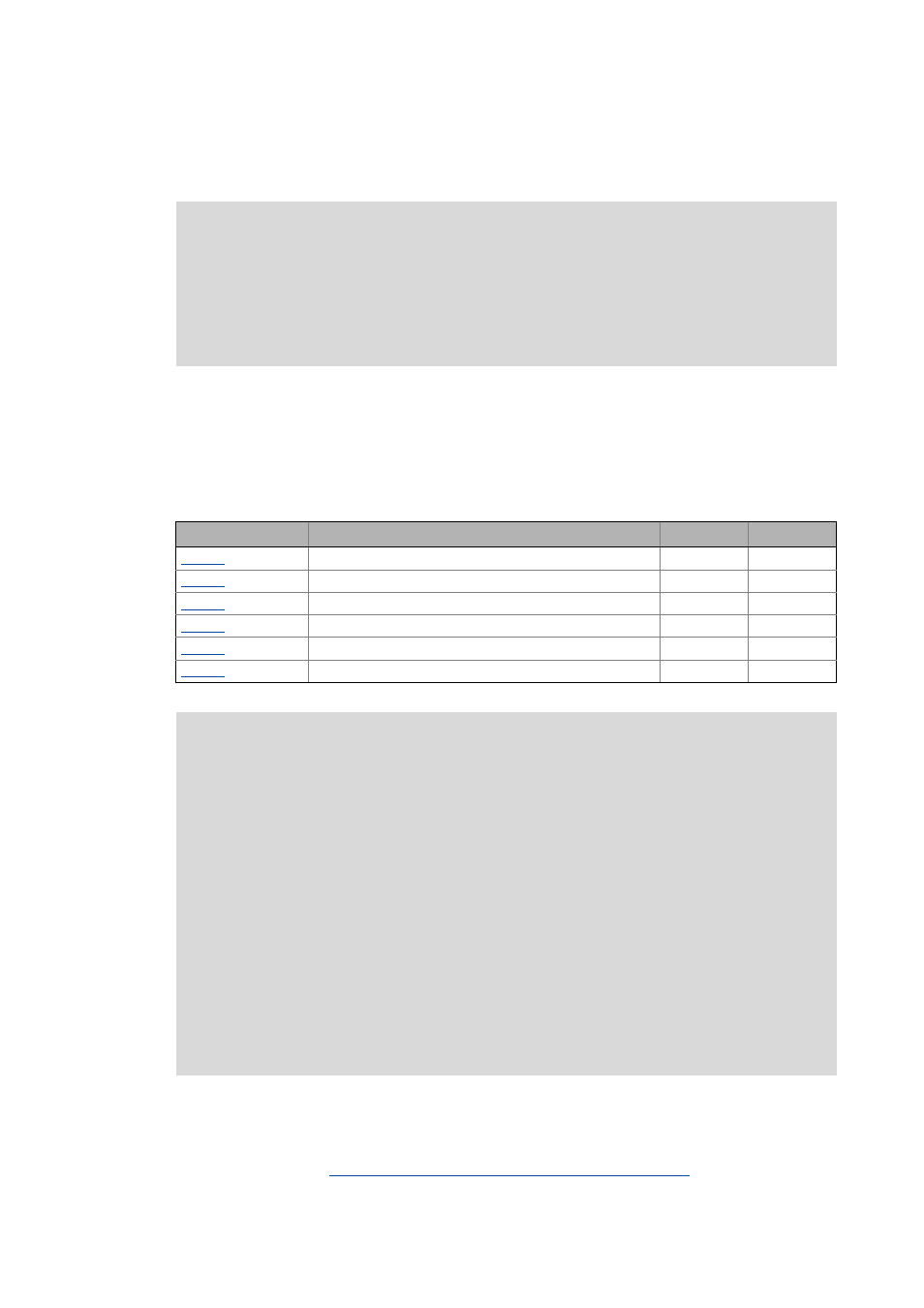

Parameter

Info

ASM

SM

Mutual motor inductance

Motor rotor resistance

Motor stator resistance

Motor stator leakage inductance

Motor cosine phi

Motor magnetising current

Danger!

This procedure may only be carried out during commissioning, not during operation!

• During the procedure the motor is energised so that:

• it cannot be excluded that the connected mechanical components may move!

• the windings heat up.

If you repeat the procedure, ensure that the motor is not thermally overloaded

(particularly if no temperature feedback is used).

For software versions lower than V4.0 the following applies:

• If the automatic brake operation is used, ensure that no basic function is requested or

that the application is stopped before this procedure is called. Otherwise the applied

holding brake could be released!

• For positioning applications you have to observe that the absolute position and the

home position will get lost when this procedure is called. The loss of the home

position is not signalled to the application. The following sequence has to be observed

for positioning applications: 1.) Execute identification 2.) Save parameter set

3.) Restart controller 4.) Execute homing procedure.