3 motor mounting direction, 4 feedback configuration, Motor mounting direction – Lenze 9400 User Manual

Page 32: Feedback configuration, 4drive interface

4

Drive interface

4.1

Machine parameters

32

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.1.3

Motor mounting direction

Depending on the motor mounting position, you can carry out an inversion of the direction of

rotation via the Motor mounting direction list field (

), if required:

•

= "0": Clockwise rotating motor ≡ positive machine direction.

•

= "1": Counter-clockwise rotating motor ≡ positive machine direction.

4.1.4

Feedback configuration

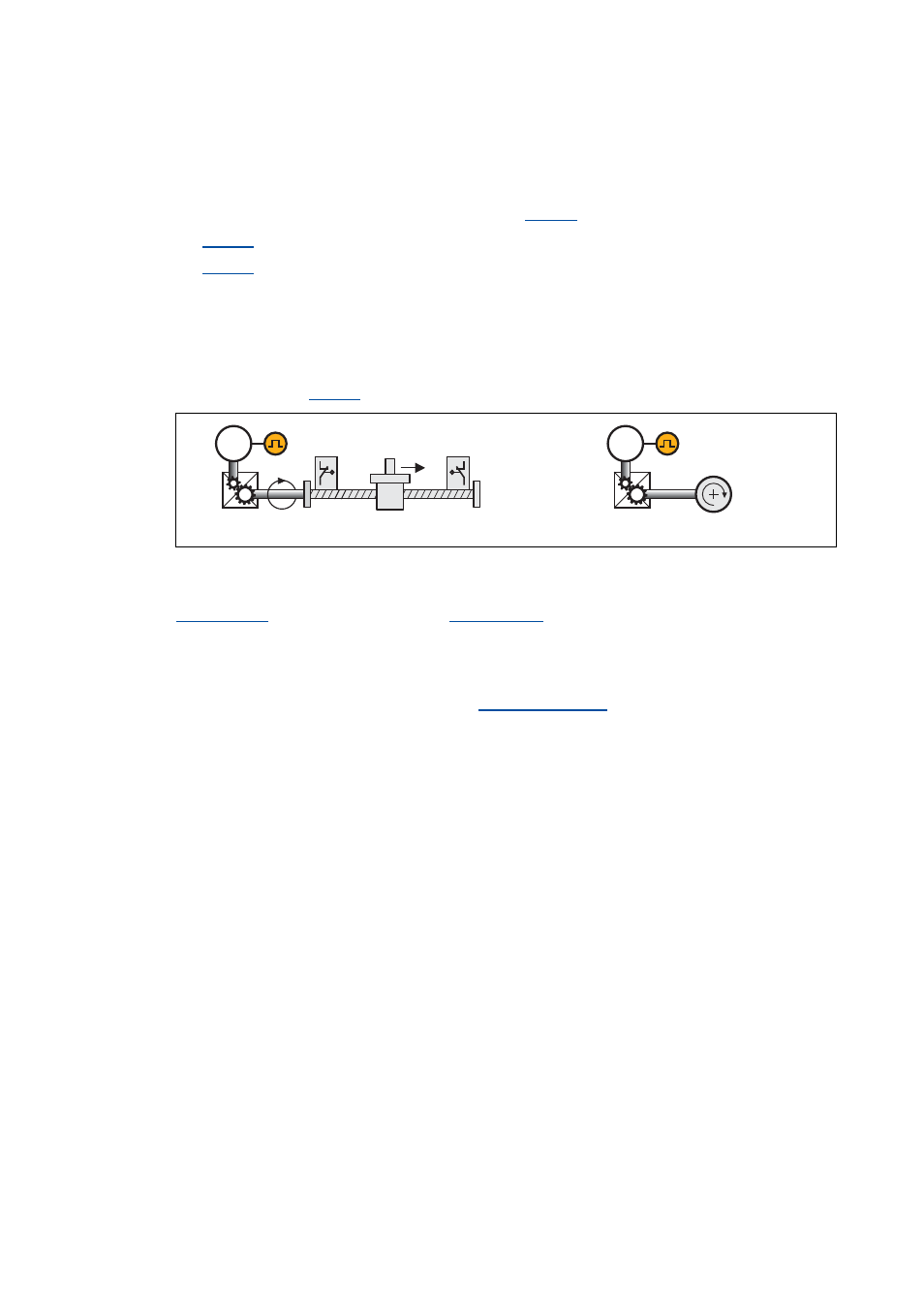

In most cases the system only has one motor encoder, i.e. no separate position encoder is installed

on the load side. The motor position (angle of rotation) and motor speed are detected via the motor

encoder selected in

and converted with regard to the load side.

[4-4]

Schematic diagram - feedback with position encoder = motor encoder

The actual position and speed values on the machine side result from the conversion via the

on the motor side and the

.

Tip!

Detailed information on the parameterisation of the feedback systems for the motor

control can be found in the chapter "

Motor encoder

M

M