5motor interface – Lenze 9400 User Manual

Page 133

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06

133

5

Motor interface

5.3

Adjusting motor and controller to each other

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

• The ramp time can be adjusted proportionally in

.

• For large machines and high mass inertia values, the ramp time usually has to be increased.

• For small machines, a reduction of the ramp time can speed up the pole position

identification process.

• In some situations it may be helpful to reverse the travel direction (

) for the pole position

identification (e.g. for linear motor at the end stop).

• The "pole position identification 360°" procedure comprises a plausibility check. If the rotor

position determined via the encoder system does not correspond to the controlled output

position:

• the pole position identification procedure is aborted.

• the response parameterised in

(Lenze setting: "Fault") is activated.

• the error message "Pole position identification cancelled" is entered into the logbook of the

controller.

• The preset fault tolerance for the plausibility check can be changed via

Parameters for the pole position identification with minimal movement

• The current amplitude can be adjusted proportionally in

• For large machines and high mass inertia values or for linear direct drives, the current

amplitude usually has to be increased.

• The Lenze setting "100 %" corresponds to the smaller of the two following values:

Note!

If the current amplitude is set to 100 % in

>, the device utilisation (Ixt)

monitoring and/or one of the motor monitoring functions may respond and cause the

abort of the pole position identification.

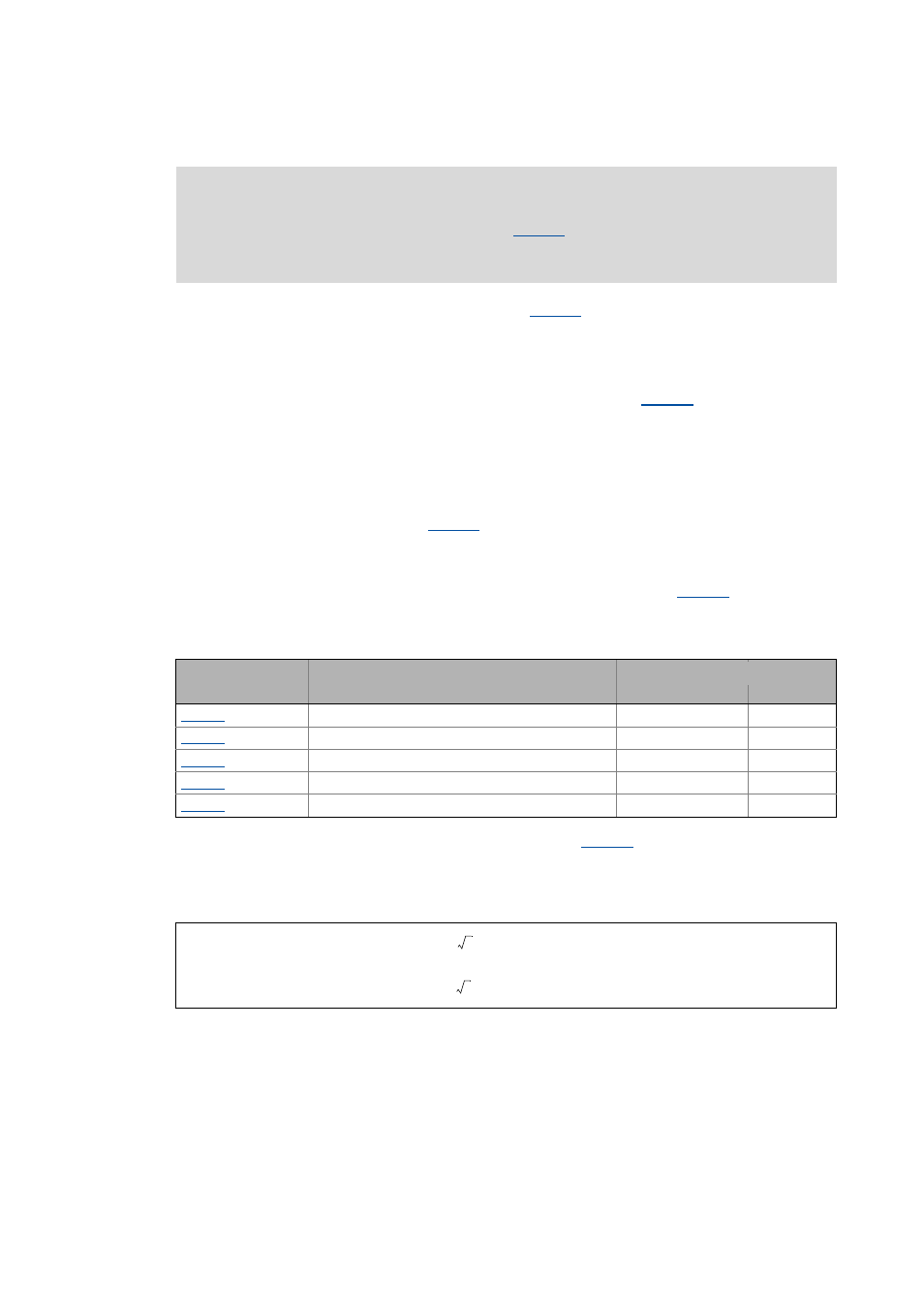

Parameter

Info

Lenze setting

Value Unit

PolePosId min.mov. cur. amp.

100 %

PolePosId min.mov. cur.rise rate

100 %

PolePosId min.mov. gain Vp

0

PolePosId min.mov. reset time Tn

62.5 ms

PolePosId min.mov. max.perm.mov.

20 °

or

25 %

2 Rated device current

⋅

⋅

25 %

2 Rated motor current

⋅

⋅