5 optimising response to setpoint changes, Optimising response to setpoint changes, 5motor interface – Lenze 9400 User Manual

Page 154

5

Motor interface

5.4

Servo control (SC)

154

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.4.1.5

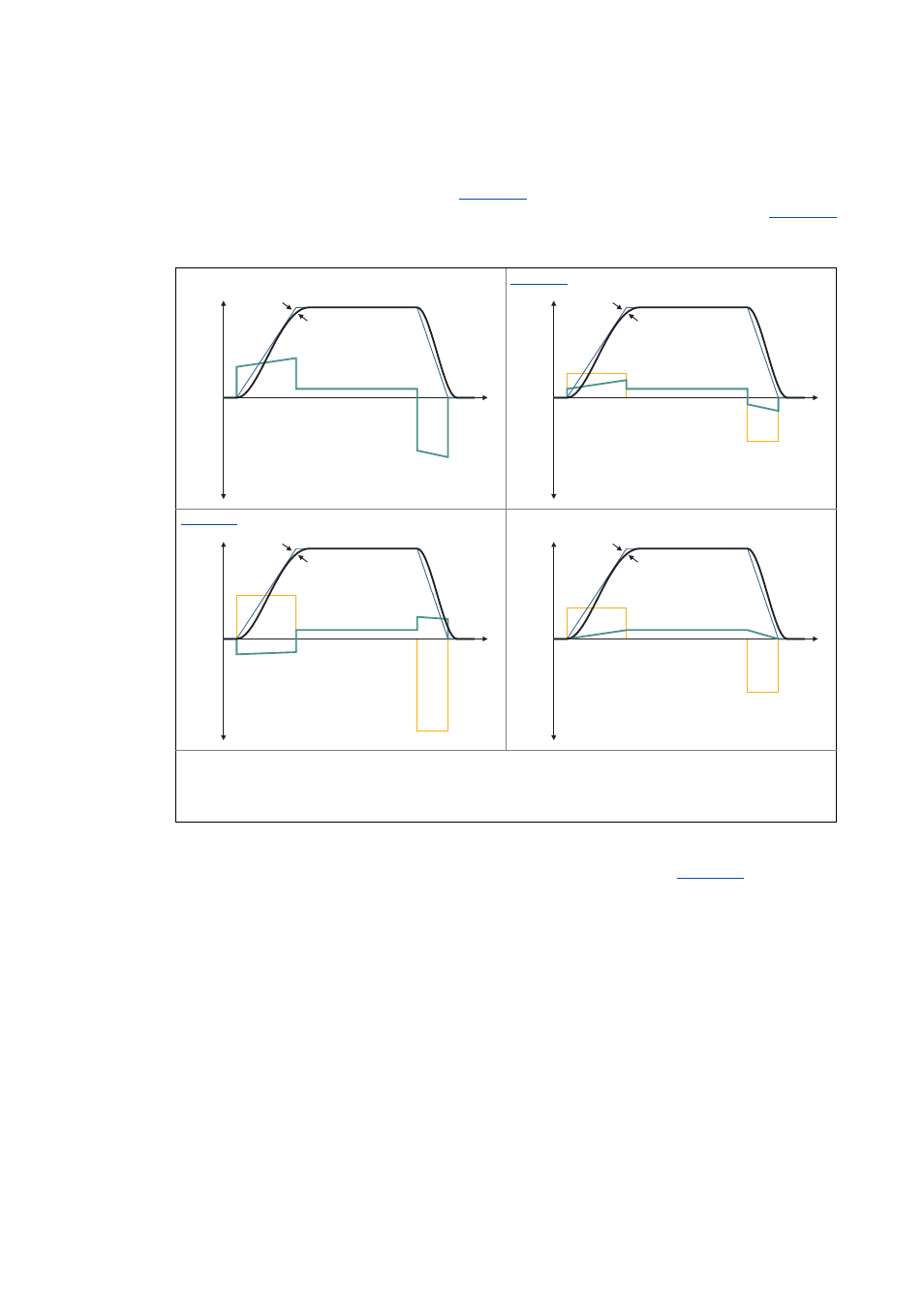

Optimising response to setpoint changes

Setting the load moment of inertia under

does not always provide the optimum torque

feedforward control. Depending on the application, an adjustment of the setting under

may be necessary to optimise the response to position/speed setpoint changes by means of the

torque feedforward control.

[5-4]

Typical signal characteristics for different settings of the load moment of inertia

Apart from the load moment of inertia, effects can be compensated with

, which in the

closed speed control loop are identified by the speed controller. These for example include the

friction torques.

Below you will find a description of a procedure for optimising the feedforward control behaviour

starting from the system's moment of inertia.

Without feedforward control:

set too low:

set too high:

Optimum feedforward control:

Speed setpoint (Speed.dnSpeedSetpoint signal)

Actual speed value (Speed.dnActualMotorSpeed signal)

Speed controller output (Torque.dnOutputSpeedCtrl signal)

Torque feedforward control (Torque.dnTotalTorqueAdd signal)

n, M

t

t

n, M

t

n, M

t

n, M