3 process data transfer, 12 profibus/profinet option – Lenze 8400 User Manual

Page 701

Lenze · 8400 protec HighLine · Reference manual · DMS 3.0 EN · 03/2013 · TD05

701

12

PROFIBUS/PROFINET option

12.3

Process data transfer

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

12.3

Process data transfer

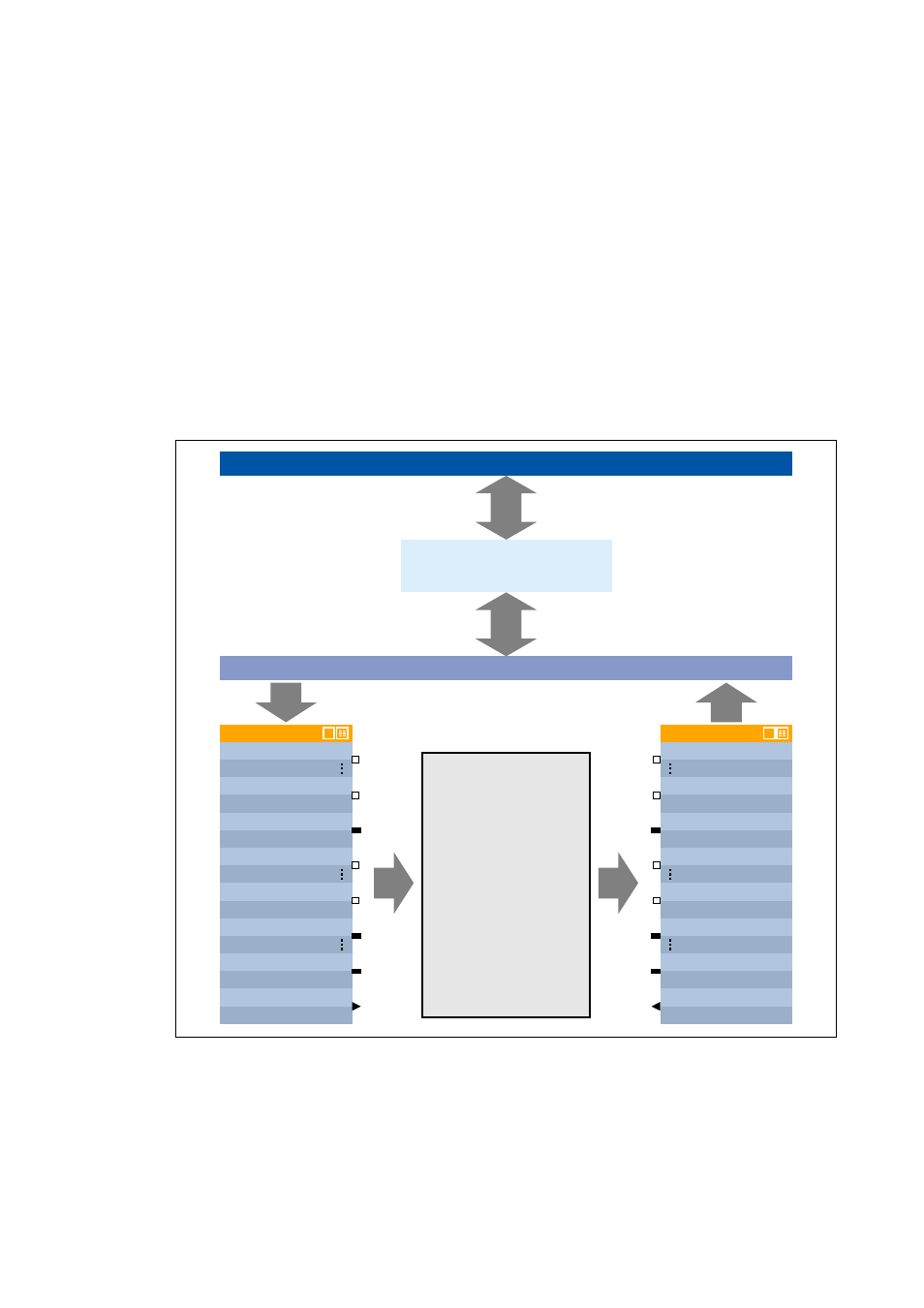

The process data serve to control the controller. Thus the transfer of the process data is time-critical.

• The process cycle is 1ms, irrespective of the respective communication option and the type of

controller.

• Process data transfer takes place cyclically between the master system and the drive controllers.

• This concerns the continuous exchange of current input and output data.

• In the case of the 8400 protec HighLine controller, 16 words per direction are exchanged.

• The master computer can directly access the process data.

Access to the process data takes place via the port blocks LP_MciIn and LP_MciOut (see FB

interconnection of the »Engineer«).

These port blocks are also called process data channels.

• The process data are not saved in the controller.

[12-1] External and internal data transfer between bus system, drive controller and function block interconnection

/3B0FL,Q

"

E&WUOB%

E&WUOB%

Z&WUO

E,QB%

E,QB%

Z,Q

Z,Q

GQ,QBS

/3B0FL2XW

E6WDWHB%

E6WDWHB%

Z6WDWH

E2XWB%

E2XWB%

Z2XW

Z2XW

GQ2XWBS

"

)LHOGEXV

$SSOLFDWLRQ

)%LQWHUFRQQHFWLRQ

&RPPXQLFDWLRQRSWLRQ

0&,LQWHUIDFH