9diagnostics & error management – Lenze 8400 User Manual

Page 578

9

Diagnostics & error management

9.8

Maloperation of the drive

578

Lenze · 8400 protec HighLine · Reference manual · DMS 3.0 EN · 03/2013 · TD05

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

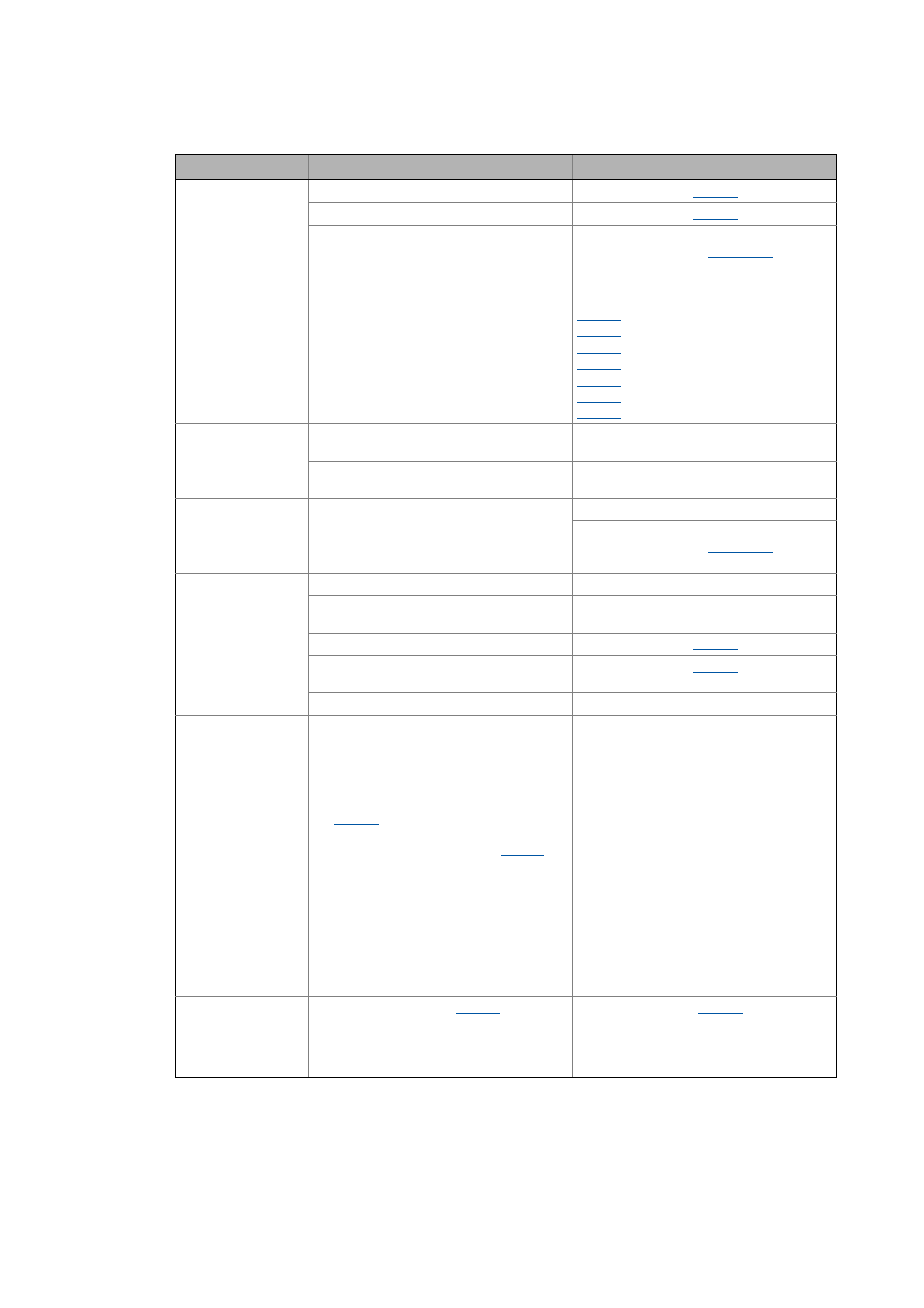

Motor consumes too

much current

V

min

boost has been selected too high

V/f base frequency has been selected too low Correct setting with

Rated motor data (stator resistance, speed,

current, frequency, voltage) and cos ϕ

and/or magnetising inductance is not

adapted to the motor data

Execute automatic motor parameter

identification with the

device

command

- or -

Adjust motor parameters manually:

: Motor stator resistance

: Rated motor speed

: Rated motor current

: Rated motor frequency

: Rated motor voltage

: Motor cosine phi

: Motor magnetising inductance

Motor parameter

identification is

aborted with error

LP1

Motor is too small compared to the rated

device power (>1 : 3)

Use device with lower rated power

DC injection brake (DCB) is active via

terminal

Deactivate DC injection brake

Drive behaviour with

vector control is not

satisfactory

different

Optimise or manually adapt vector control

Execute automatic motor parameter

identification with the

device

command

Torque dip in field

weakening range

or

motor stalling when

being operated in the

field weakening

range

Motor is overloaded

Check motor load

Motor windings are wired incorrectly

Reverse from star connection to delta

connection

V/f reference point is set too high

Override point of field weakening is set too

low

Mains voltage too low

Increase mains voltage

An asynchronous

motor with feedback

rotates without

control and with too

low speed

Motor phases have been interchanged

• Thus the rotating field of the motor is not

identical anymore with the rotating field

of the feedback system.

• Therefore, the drive shows the following

behaviour if V/f characteristic control

= 7) is performed:

• The motor rotates faster than the speed

setpoint by the value set in

.

• After the controller has been enabled,

the controller will not stop if the speed

setpoint = 0 or a quick stop (QSP)

occurs.

• Among other things, the final motor

current depends on the value set for the

V

min

boost and may rise up to I

max

which can trigger the "OC5: Ixt

overload" fault message.

Check the phase position of the motor cable

If possible: Actuate the motor with

deactivated feedback (

= 6) and check

direction of rotation of the motor

Motor phase (LP1)

monitoring does not

respond if the motor

phases are

interrupted

Monitoring is not active (

= 0)

Activate monitoring (

= 1)

Maloperation

Cause

Remedy