18 function library – Lenze 8400 User Manual

Page 1261

Lenze · 8400 protec HighLine · Reference manual · DMS 3.0 EN · 03/2013 · TD05

1261

18

Function library

18.1

Function blocks | L_DFRFG_1

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

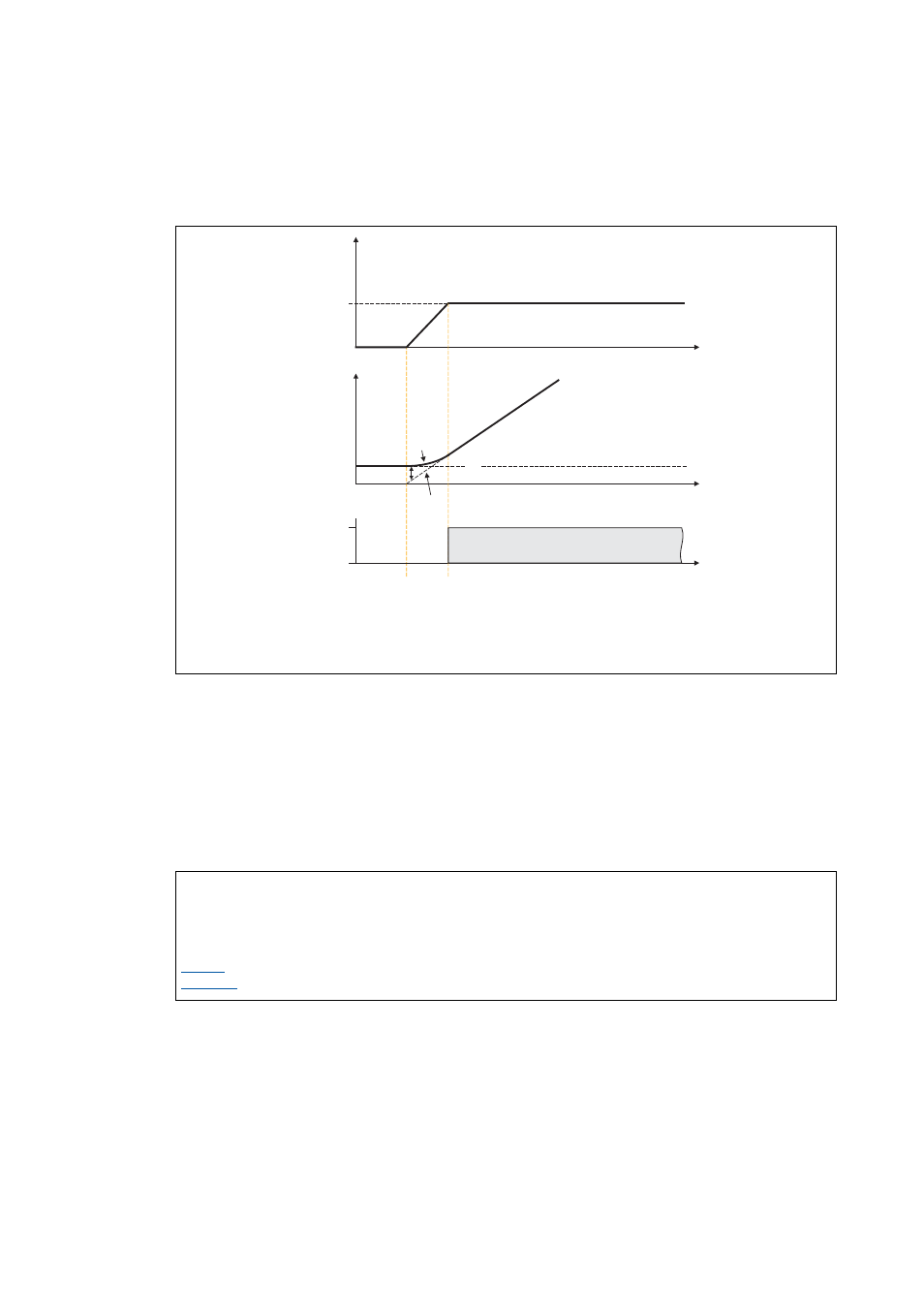

Behaviour with offset

By selecting an offset, the actual position is preloaded with a non-zero value. This reduces the

distance and the time to synchronicity.

[18-33] Example 1: With offset selection

• When a positive offset is selected, the sign of the distance between setpoint and actual value

changes. This distance is reduced due to the acceleration of the slave from the input of the touch

probe pulse. Thus, the time to synchronicity is shorter.

• The offset refers to the master value selection and is scaled with an encoder revolution

(≡ 65536 increments).

• The offset can be determined empirically, but it is sensible to calculate the required acceleration

distance and select this value as offset:

Difference between setpoint angle and actual angle (ϕ

DIFF

)

Offset [inc]

t

0

= touch probe event

t

1

= synchronicity achieved

j

t

TRUE

FALSE

bSync

t

v

nIn_v

t

j

SET

j

ACT

t

0

t

1

ϕ

ACC

= acceleration distance in [increments]

v

SET

= setpoint speed in [rpm]

= reference speed of the motor in [rpm]

= acceleration/deceleration time of the ramp generator in [ms]

ϕ

ACC

1

2

---

V

SET

(

)

2

C00011 [rpm]

-----------------------------------

C01076/1 [ms] 16384 [incr./ms]

15000 [rpm]

-------------------------------------------

⋅

⋅

⋅

=