Oc12, Oc12: i2xt brake resistor overload, Oc12: i2xt overload brake resistor – Lenze 8400 User Manual

Page 595: Xx.0123.00060, Xx.0123.00071, Xx.0123.00065, Xx.0123.00090, 9diagnostics & error management

Lenze · 8400 protec HighLine · Reference manual · DMS 3.0 EN · 03/2013 · TD05

595

9

Diagnostics & error management

9.10

Error messages of the operating system

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

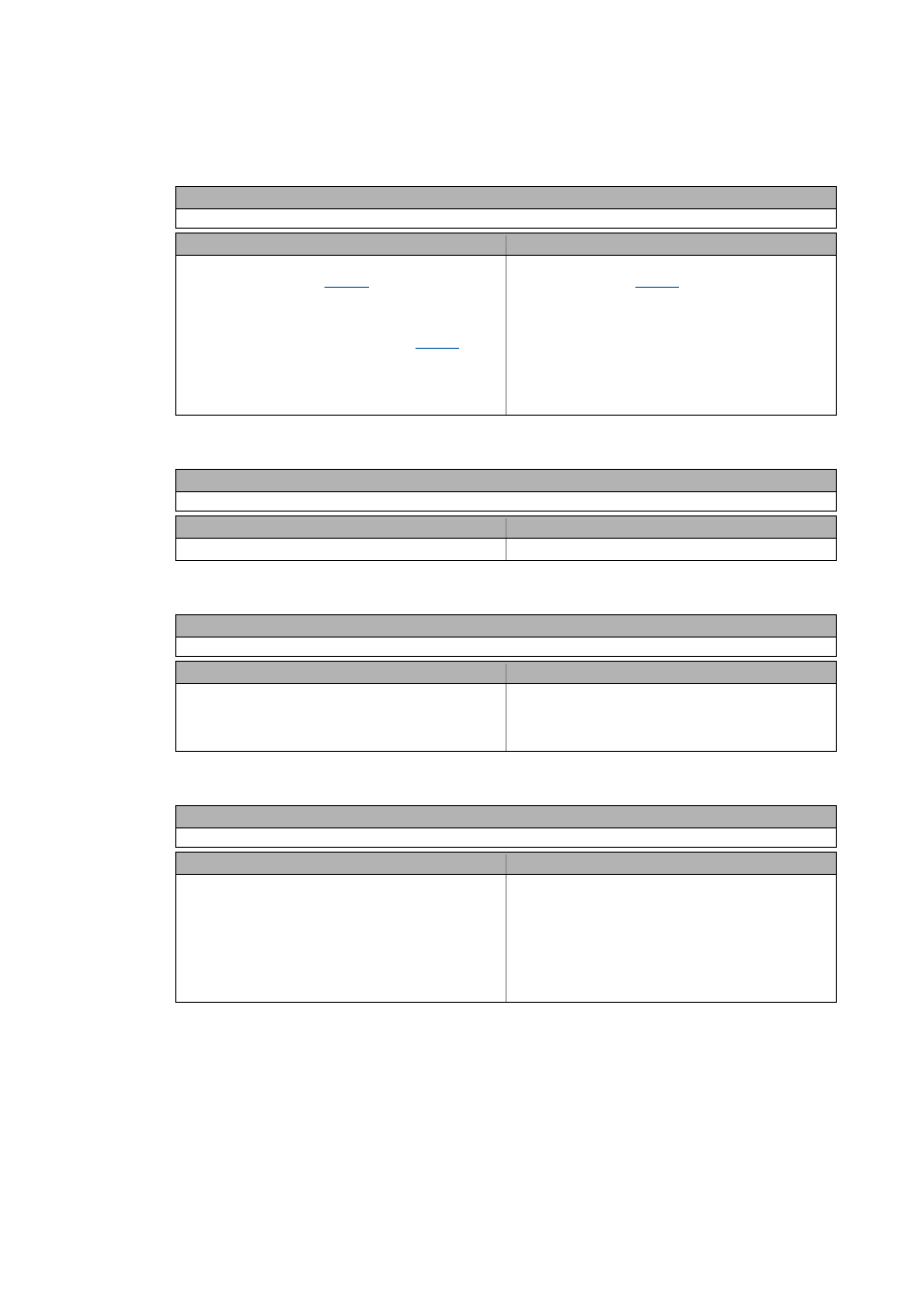

Id7: Motor control does not match motor data [xx.0123.00060]

oC12: I2xt overload - brake resistor [xx.0123.00065]

oC11: Clamp operation active [xx.0123.00071]

oC13: Maximum current for Fch exceeded [xx.0123.00090]

Response (Lenze setting printed in bold)

0: No Reaction 1: Fault 2: Trouble 3: TroubleQuickStop 4: WarningLocked 5: Warning 6: Information

Cause

Remedy

At controller enable, the device has detected that the

cannot control the

motor type set.

• Example: Motor nameplate data for an asynchronous

motor have been entered; however, a motor control

type for a synchronous motor is set in

.

Note:

Since the "VFCplus" control types are able to control

every motor to a certain extent, this error message will

never occur here.

Enter correct motor nameplate data and set a matching

motor control type in

:

• Motor nameplate data asynchronous motor motor

control type must be ASM, SLVC or VFCplus servo

control.

• Motor nameplate data synchronous motor motor

control type must be PSM, SLPSM or VFCplus servo

control.

Response (Lenze setting printed in bold)

0: No Reaction 1: Fault 2: Trouble 3: TroubleQuickStop 4: WarningLocked 5: Warning 6: Information

Cause

Remedy

Too frequent and too long braking processes.

Check drive dimensioning.

Response (Lenze setting printed in bold)

0: No Reaction 1: Fault 2: Trouble 3: TroubleQuickStop 4: WarningLocked 5: Warning 6: Information

Cause

Remedy

The device indicates that the "CLAMP" overcurrent

limitation has been activated.

• A permanent clamp operation causes an overload

disconnection.

Reduce setpoint generation dynamics or motor load.

Response (Lenze setting printed in bold)

0: No Reaction 1: Fault 2: Trouble 3: TroubleQuickStop 4: WarningLocked 5: Warning 6: Information

Cause

Remedy

The device has detected a motor current which exceeds

the maximum current limit at permanent switching

frequency of the inverter.

• If a permanent switching frequency inverter is set, a

certain limit arises for the maximum current,

depending on the setting. If this current limit is

exceeded due to a load impulse or overload, an error

message is displayed.

• Observe the maximum current setting depending on

the set switching frequency of the inverter.

• Reduce the required load or setting of the dynamic

switching frequency if necessary.