5motor control (mctrl) – Lenze 8400 User Manual

Page 274

5

Motor control (MCTRL)

5.13

Braking operation/brake energy management

274

Lenze · 8400 protec HighLine · Reference manual · DMS 3.0 EN · 03/2013 · TD05

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

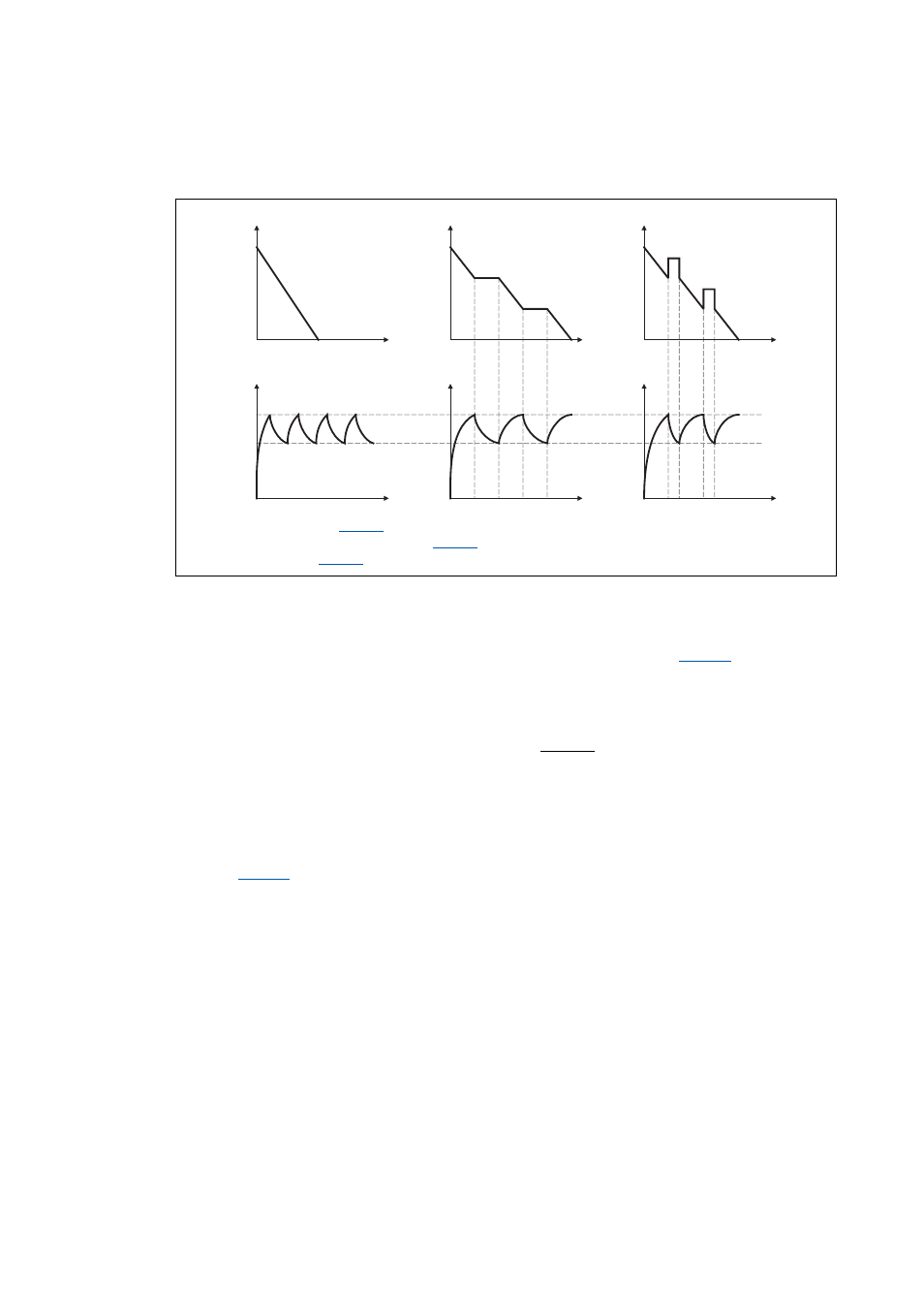

The way in which the different braking procedures work is demonstrated schematically in the

following illustration:

[5-30] Graph of the effective speed setpoint and the DC bus voltage during braking

Tip!

Independent of the selected motor control, all procedures given in

The actual speed value can optimally follow the speed setpoint when a brake resistor is

used.

If it is possible to dispense with exact adherence to the deceleration ramp in simple

applications, selection of a braking method without an external brake resistor enables

costs to be reduced due to the avoidance of having to use a brake resistor .

With the "inverter motor brake" function, an effective braking torque of 10 ... 20 % of the

rated motor torque can be achieved.

A combination of all three braking procedures is also possible, e.g. for emergency braking if

the brake resistor fails

(

= "4: Brake resistor + FI_MotBrk + RfgStop").

Use of the brake resistor (

Stopping of the ramp function generator (

= "1: HlgStop")

Inverter motor brake (

= "3: FI_MotBrk + RfgStop)

n

Set

t

n

Set

t

1

2

n

Set

t

0

t

t

t

U

DC

U

DC

U

DC