4 optimising the control mode, Optimising the control mode, 5motor control (mctrl) – Lenze 8400 User Manual

Page 228

5

Motor control (MCTRL)

5.9

Servo control (SC)

228

Lenze · 8400 protec HighLine · Reference manual · DMS 3.0 EN · 03/2013 · TD05

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.9.4

Optimising the control mode

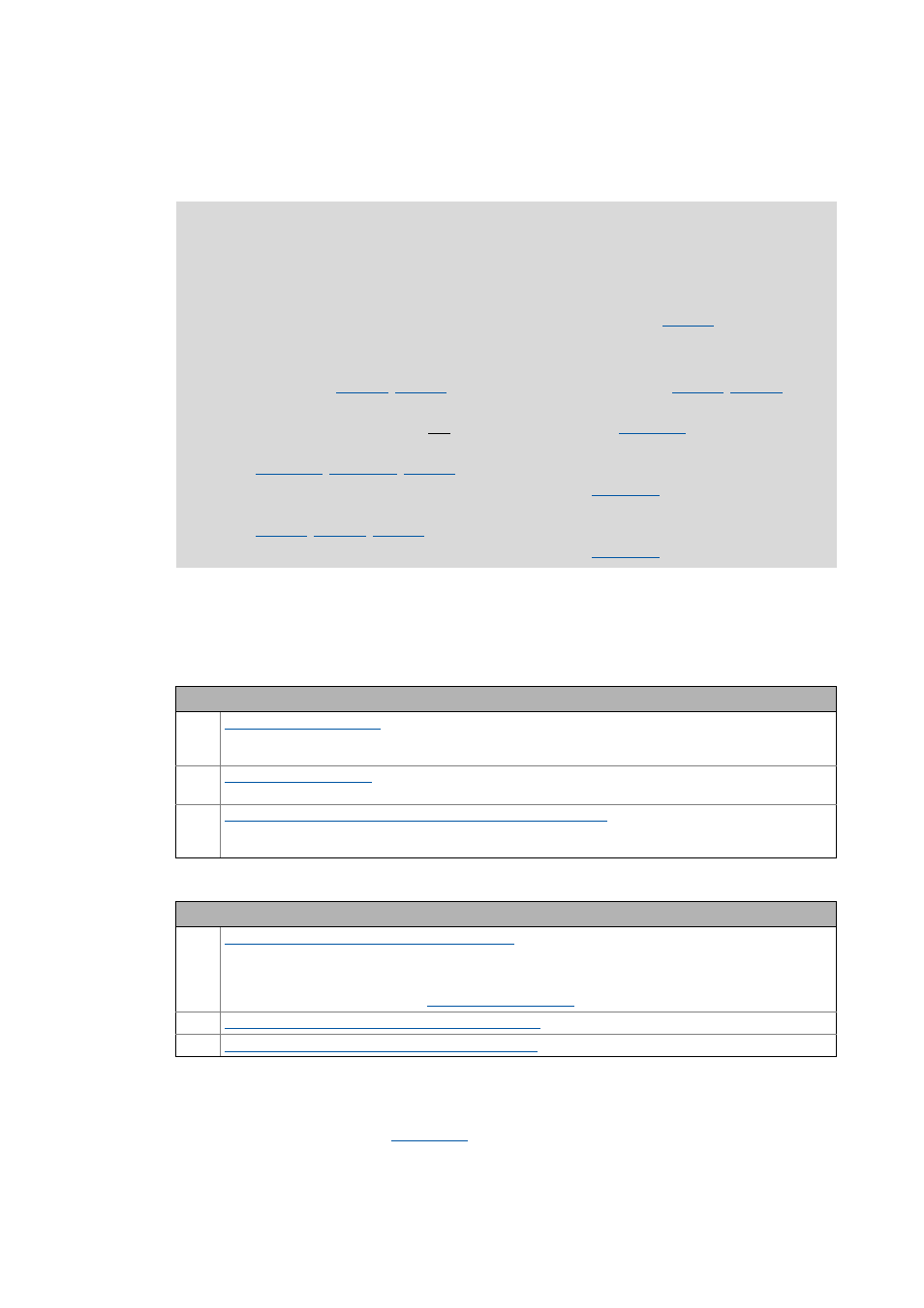

The "optimisation steps" given in the table below serve to further optimise the control behaviour of

the servo control and adjust it to the concrete application.

• Detailed information on the individual steps can be found in the following subchapters.

Generally, the following optimisation steps are recommended:

Special cases may require further optimisation steps:

Tip!

In order to traverse a typical speed profile for optimisation of motor control, you can also

use the basic function "

" with appropriately adapted manual jog parameters if

this basic function is supported by the selected technology application.

Note!

When the controller has been enabled, starting up is delayed by the magnetization

process of the motor. The speed setpoint is only enabled for motor control if 87 % of the

motor magnetising current are available. If this delay is not tolerable for certain

applications, the preset percentage threshold can be reduced in

.

From version 12.00.00:

• Following successful motor parameter identification, the current controller

parameters (

) and field controller parameters (

calculated automatically.

• If these parameters are not to be calculated, bit 4 of

must be set to "1".

• Following successful motor parameter identification, the speed controller parameters

(

) can be calculated automatically.

• If these parameters are to be calculated, bit 6 of

must be set to "5".

• Following successful motor parameter identification, other controller parameters

(

) can be calculated automatically.

• If these parameters are to be calculated, bit 6 of

must be set to "6".

Optimisation steps

1.

• The current controller should always be optimised if a motor of a third-party manufacturer with

unknown motor data is used!

2.

• The setting of the speed controller must be adapted depending on the mechanical path.

3.

Optimise response to setpoint changes and determine mass inertia

• For an optimal reference behaviour, the total moment of inertia can be used to make a feedforward

control of the speed setpoint.

Optimisation steps

1.

Setting the current setpoint filter (band-stop filter)

• In order to suppress or damp (mechanical) resonant frequencies, a current setpoint filter is integrated in

the speed control loop which is switched off in the default setting but can be parameterised accordingly,

if required.

Then readjust the speed controller:

2.

Adapting the max. acceleration change (jerk limitation)

3.

Optimising the behaviour in the field weakening range