0x00850000, 0x00860020, 0x00860000 – Lenze E94AxPExxxx User Manual

Page 700: 14 diagnostics & fault analysis

14

Diagnostics & fault analysis

14.7

Error messages of the operating system

700

Lenze · 9400 Servo PLC· Reference manual · DMS 4.0 EN · 11/2013 · TD05/06

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

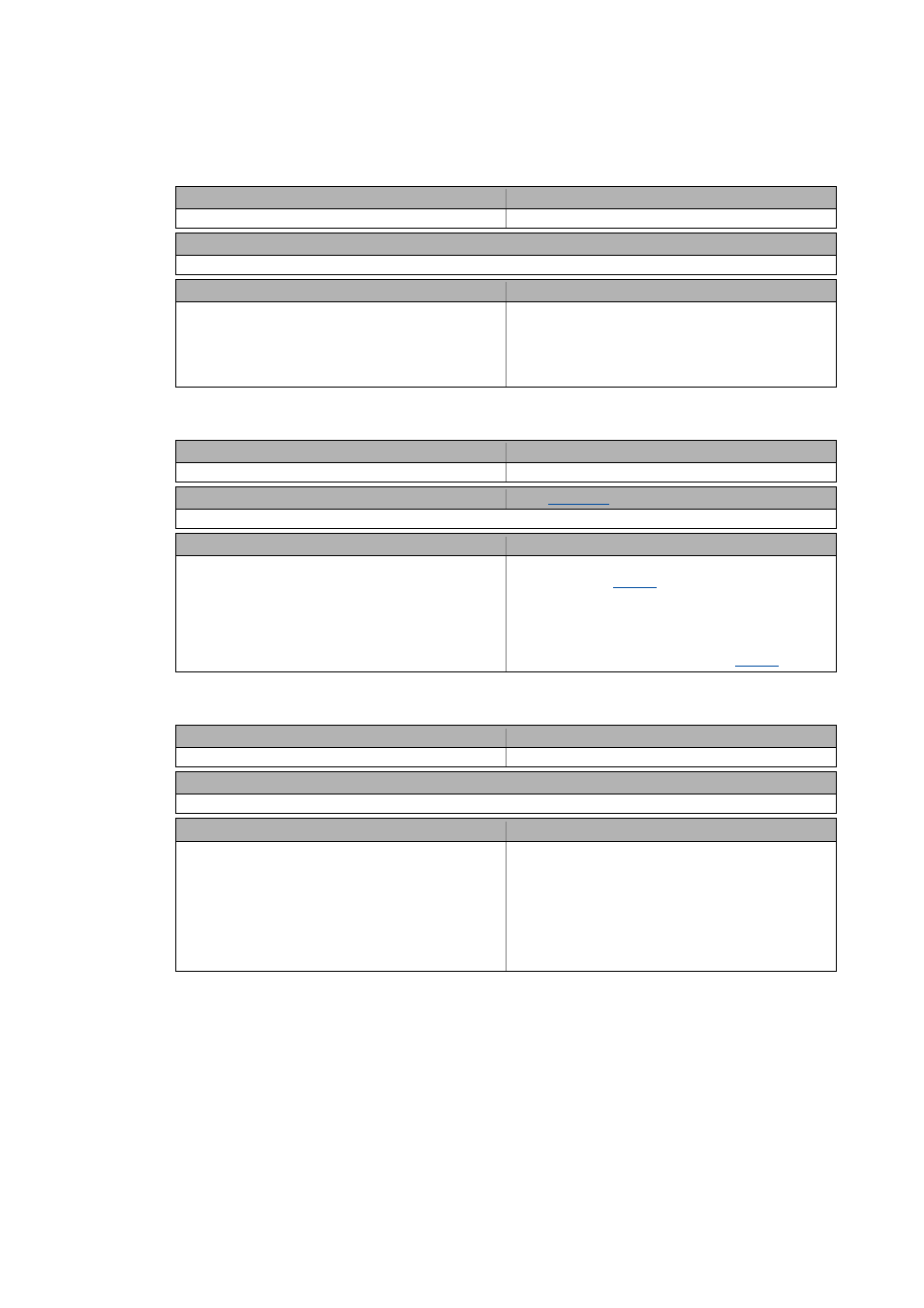

CAN on board: Faulty emergency configuration [0x00850000]

CAN on board: Node guarding error 1 ... 32 [0x00860000 ... 0x0086001f]

CAN on board: Faulty NMT master configuration [0x00860020]

Module ID (decimal)

Error ID (decimal)

133: "CAN on board": CAN emergency handler

0

Response (Lenze setting printed in bold)

None System fault Fault Trouble Quick stop by trouble Warning locked Warning Information

Cause

Remedy

CAN on board: CAN emergency configuration is faulty.

• Faulty download of an Engineer or PLC Designer

project

• Invalid CAN emergency settings according to

DS301V402 in the Engineer or PLC Designer.

• Repeat download

• Correct CAN settings in the project and regenerate

project.

Module ID (decimal)

Error ID (decimal)

134: "CAN on board": CAN-NMT master

0 ... 31

Response (Lenze setting printed in bold)

Setting:

( Adjustable response)

None System fault Fault Trouble Quick stop by trouble Warning locked Warning Information

Cause

Remedy

CAN on board: Cyclic node monitoring

• CAN master has not received a response to a node

guarding telegram (remote transmission request

telegram) from node 1 ... 32 within the defined time.

• Reactivate CAN node by mains switching, restart of

the controller (

="11000") or CAN reset node.

• Select a different node guarding monitoring time or

switch off monitoring.

• Reset potentially caught error status.

Tip: Save the current parameter set before mains

switching and restart of the controller (

="11").

Module ID (decimal)

Error ID (decimal)

134: "CAN on board": CAN-NMT master

32

Response (Lenze setting printed in bold)

None System fault Fault Trouble Quick stop by trouble Warning locked Warning Information

Cause

Remedy

CAN on board: A configuration error has occurred in the

network management of the CAN master.

• Faulty download of an Engineer or PLC Designer

project.

• Invalid CAN master settings according to DS301V402

and DS405 in the Engineer or PLC Designer.

• Incorrect parameterisation of node guarding or

heartbeat.

• Repeat download

• Correct CAN settings in the project and regenerate

project.