5 brake time response, 12 basic drive functions, Danger – Lenze E94AxPExxxx User Manual

Page 561

Lenze · 9400 Servo PLC· Reference manual · DMS 4.0 EN · 11/2013 · TD05/06

561

12

Basic drive functions

12.12

Brake control

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

12.12.2.5 Brake time response

Application and release time

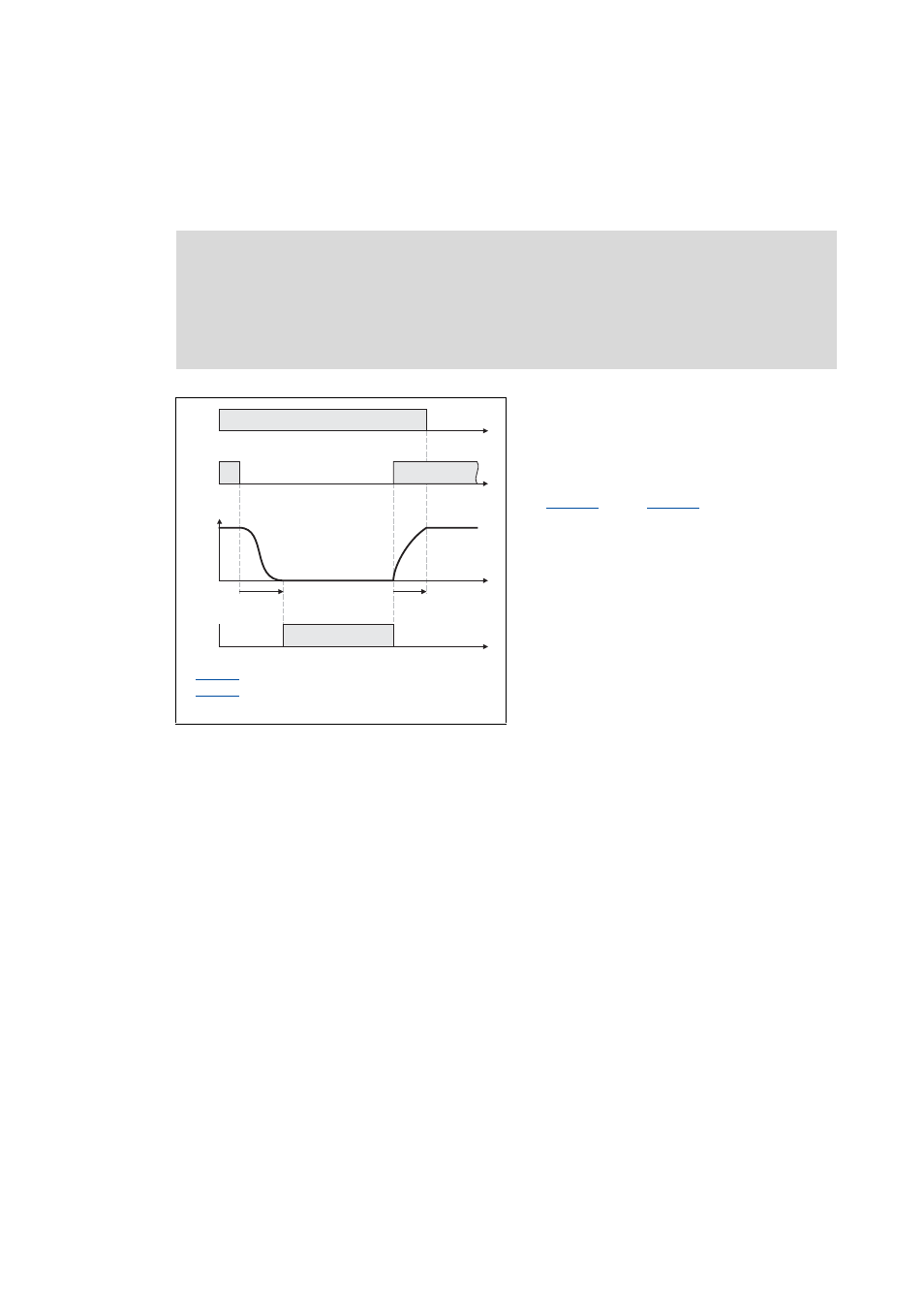

[12-35] Definition of the application and release time with the example of the PM brake

Tip!

The application and release times do not only vary between the brake types but also

depend on the basic conditions in the plant:

• Parameters of the hardware (cable length, temperature, level of supply voltage etc.)

• Contact elements used (motor brake control module or contactor at the digital output)

• Type of overvoltage limitation/suppressor circuit

For optimisation purposes, detect in individual cases the response times by measurement.

Danger!

A wrong setting of the closing and opening time can cause a wrong activation of the

motor holding brake!

• When the closing time is set too low, the controller is inhibited and the drive gets

torqueless before the motor holding brake is closed completely.

: Brake closing time

: Brake opening time

CINH = controller inhibit

• Every mechanical motor holding brake has

a construction-conditioned application

and opening time which has to be taken

into consideration by the brake control and

which for this purpose has to be set in

and in

• The information on the application and

opening time of a Lenze-motor holding

brake can be found in the corresponding

Operating Instructions in the chapter

"Technical data".

• If the application and release times are too

long, this is uncritical in respect of safety

but leads to unnecessarily long delays

during cyclical braking processes.

t

t

t

CINH

t

Stopping/Standstill

BRK_bReleaseBrakeOut

I

BRK