1 accepting/adapting plant parameters, Accepting/adapting plant parameters, Accepting/adapting plant parameters ( 172) – Lenze E94AxPExxxx User Manual

Page 172: 6motor interface

6

Motor interface

6.3

Adjusting motor and controller to each other

172

Lenze · 9400 Servo PLC· Reference manual · DMS 4.0 EN · 11/2013 · TD05/06

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6.3.1

Accepting/adapting plant parameters

The "plant parameters" summarise all parameters which result from the combination of motor and

load. These characterise the transfer behaviour of the entire controlled system including the

required monitoring modes.

• The plant parameters depend on the application in which the controller and motor are used.

• When a Lenze motor is selected in the »Engineer«, plant parameters are suggested for this

motor for a load-free operation.

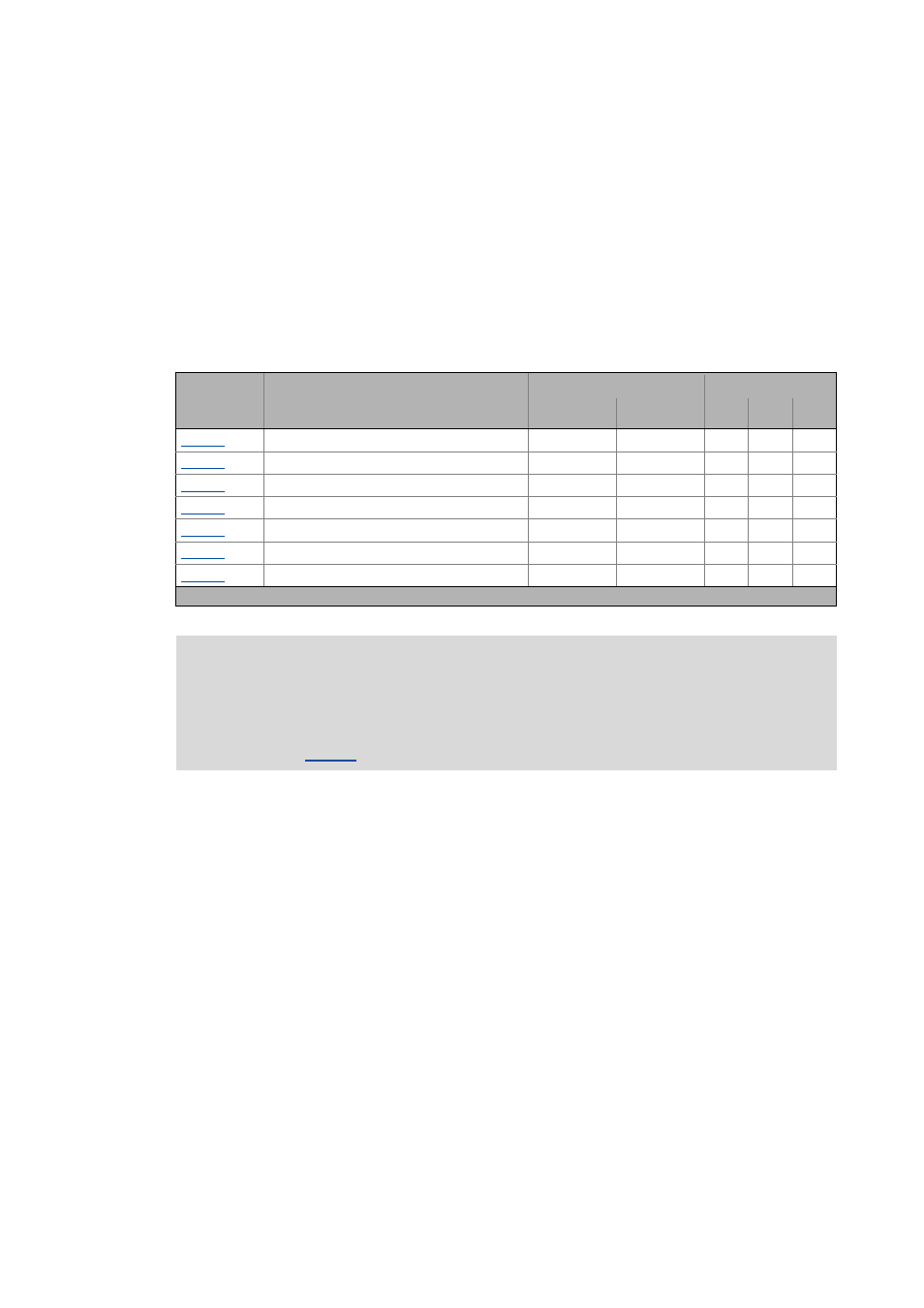

Overview of plant parameters

Parameter

Info

Lenze setting

Motor control*

Value Unit

SC

SLVC

VFC

plus

Motor reference speed

3000 rpm

Maximum current

0.00 A

Speed controller gain

0.500 Nm/rpm

1

Speed controller reset time

24.0 ms

1

Speed controller rate time

0.00 ms

Speed act. val. time const.

2.0 ms

Threshold max. speed reached

6500 rpm

* SC = servo control

SLVC = sensorless vector control

VFCplus = V/f control open loop

1

Only for V/f control closed loop

Note!

If plant data have been adapted offline in »Engineer«, all plant data have to be

transferred to the control afterwards when an online connection has been established

and have to be saved in the memory module with mains failure protection (device

command

= "11: Save start parameters").