6 maloperation of the drive, 14 diagnostics & fault analysis – Lenze E94AxPExxxx User Manual

Page 641

Lenze · 9400 Servo PLC· Reference manual · DMS 4.0 EN · 11/2013 · TD05/06

641

14

Diagnostics & fault analysis

14.6

Maloperation of the drive

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

14.6

Maloperation of the drive

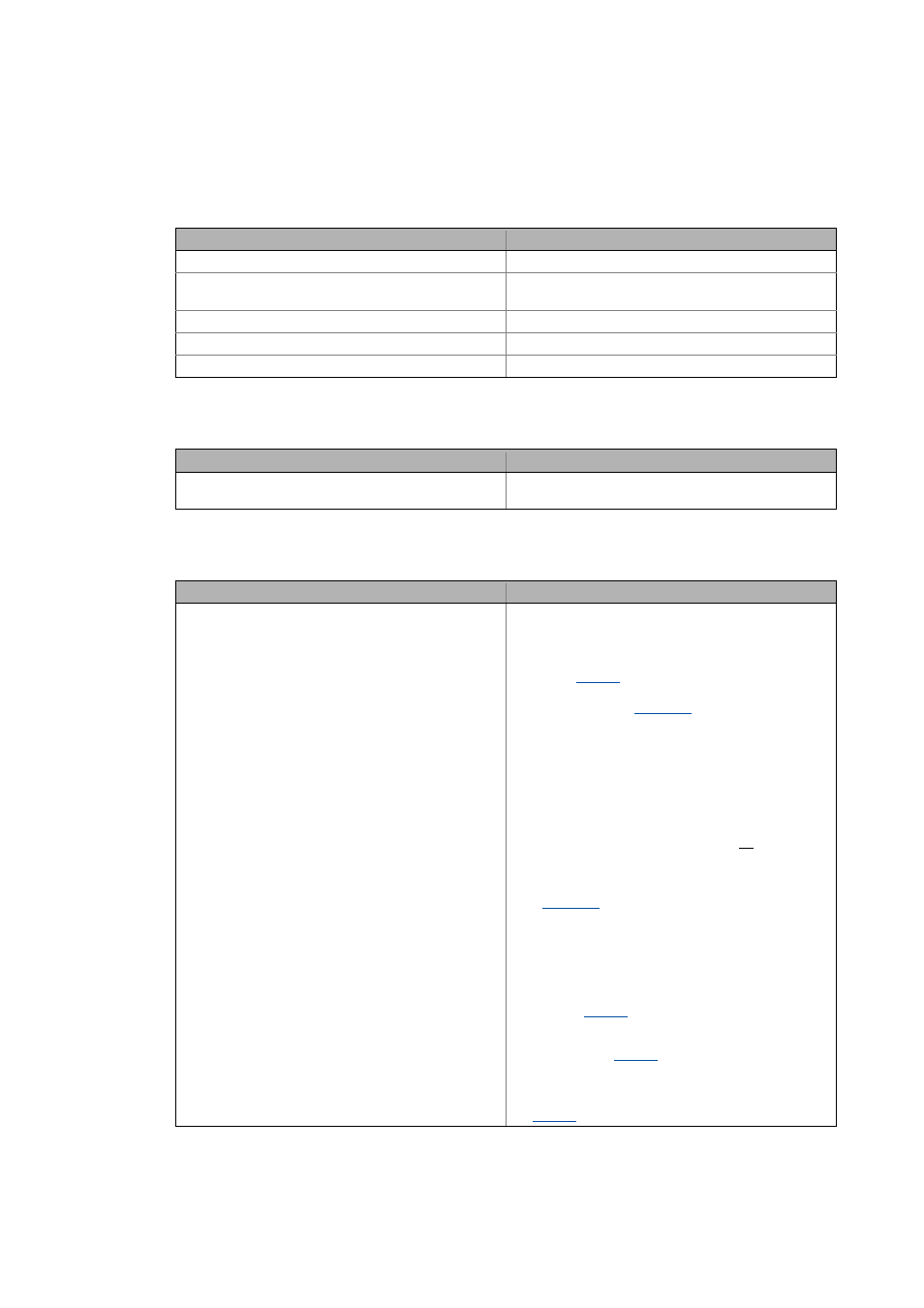

The motor does not rotate.

With a positive speed setpoint selection, the motor rotates counter-clockwise instead of clockwise

(when looking at the motor shaft).

The maximum current (C00022) flows and the motor does not rotate according to the defined

speed setpoint.

Cause

Remedy

DC-bus voltage is too low.

Check mains voltage.

Controller is inhibited.

Deactivate controller inhibit (can be set by several

sources).

Motor holding brake is not released.

Release motor holding brake.

Quick stop is active

Deactivate quick stop

Setpoint = 0

Select setpoint.

Cause

Remedy

Feedback system is not connected in correct phase

relation.

Connect feedback system in correct phase relation.

Cause

Remedy

Two motor phases are interchanged, i.e. an anti-

clockwise rotating field is applied to the motor.

Carry out the following steps for verification:

1.Ensure that the motor shaft is not blocked and can

rotate freely without damaging the system.

2.Activate the "U-rotation test mode" for the motor

control (

= "1").

• In this test mode a voltage phasor with the

frequency set in

and the amplitude from

the linear characteristic of rated voltage and rated

frequency is applied to the machine, which

corresponds to a clockwise rotating field.

• Danger!

When the test mode is active, the parameterisable

error response "Quick stop by trouble" has no

effect!

If the test mode is active and a monitoring function

responds with this error response, no quick stop is

executed but the motor continues to rotate with

the frequency set for the test mode!

3.Increase the frequency step by step for the test mode

in

until the motor shaft starts to rotate.

• If the motor shaft does not rotate, check the

electrical connection.

4.While the motor shaft is rotating, check whether it

rotates clockwise when looking at the A end shield. If

not, two motor phases are interchanged.

5.Additionally check whether the actual speed value

shown in

is positive and whether it

corresponds to the defined frequency, taking the

number of pole pairs of the machine into

consideration (

). If this is not the case, the

connection and the parameter setting of the

feedback system are to be checked.

6.Deactivate the test mode for the motor control again

(

= "0").