Axis fault – Rockwell Automation GMLC Reference Manual User Manual

Page 737

Publication GMLC-5.2 - November 1999

700

Using the RIO Adapter Option

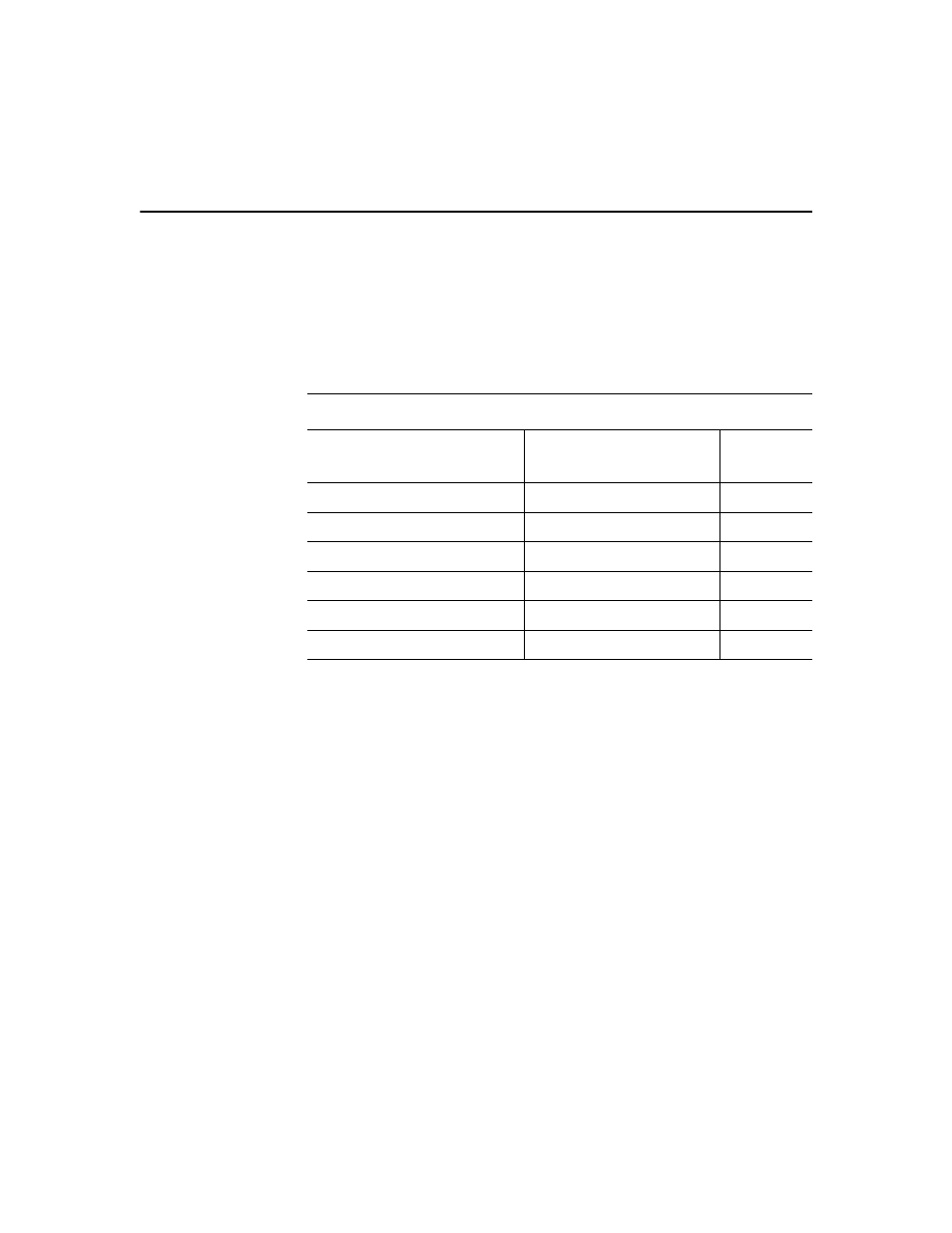

Axis Fault

The axis fault output for each axis (SLC or PLC inputs 4 – 7) is set

whenever an axis fault occurs

(Axis_fault

> 0). The next table shows

the axis faults that trigger an axis fault output, and the corresponding

message that appears in the Terminal Window (or Runtime Display, if

enabled).

If no axis faults have occurred (Axis_fault = 0), the fault output for the

axis is cleared and the message “No Fault” appears in the Terminal

Window (or Runtime Display, if enabled.)

Specifically, the axis fault output for an axis is set whenever the

corresponding Axis_fault variable in GML Commander has a value

greater than 0, and cleared whenever it has a value of 0. See the Status

Variables chapter of this manual for more information on Axis_fault.

To determine which fault is active when one of the axis fault bits is set,

the PLC should issue a block transfer read of the appropriate axis fault

status variable in the motion controller. See Using Block Transfers in this

chapter for more information.

Axis Faults

Description

On Watch & Axis System

Variable Display

Runtime

Display

Drive Fault

Drive_fault

DRV FLT

Position Error Tolerance Exceeded

Position_error_fault

ERR FLT

Hardware Overtravel Fault

Hardware_overtravel_fault

HRD LIM

Software Travel Limits Exceeded

Software_overtravel_fault

SFT LIM

Encoder Noise Fault

Encoder_noise_fault

ENC FLT

Encoder Loss Fault

Encoder_loss_fault

ENC FLT