Rockwell Automation GMLC Reference Manual User Manual

Page 553

Publication GMLC-5.2 - November 1999

516

Fault Variables

When evaluated in an expression, the value of the Position_error_fault

variable indicates whether a position error fault has occurred.

When Position_error_fault = 1, Axis_fault = 4, Axis_status = 10 if no

other faults of higher priority are active on the axis, and Global_fault = 4

if no other faults of higher priority are active on any axis. A position error

fault is usually caused by commanding a speed or acceleration that

exceeds the capability of the drive system, a jammed or stuck axis, or a

faulty feedback device.

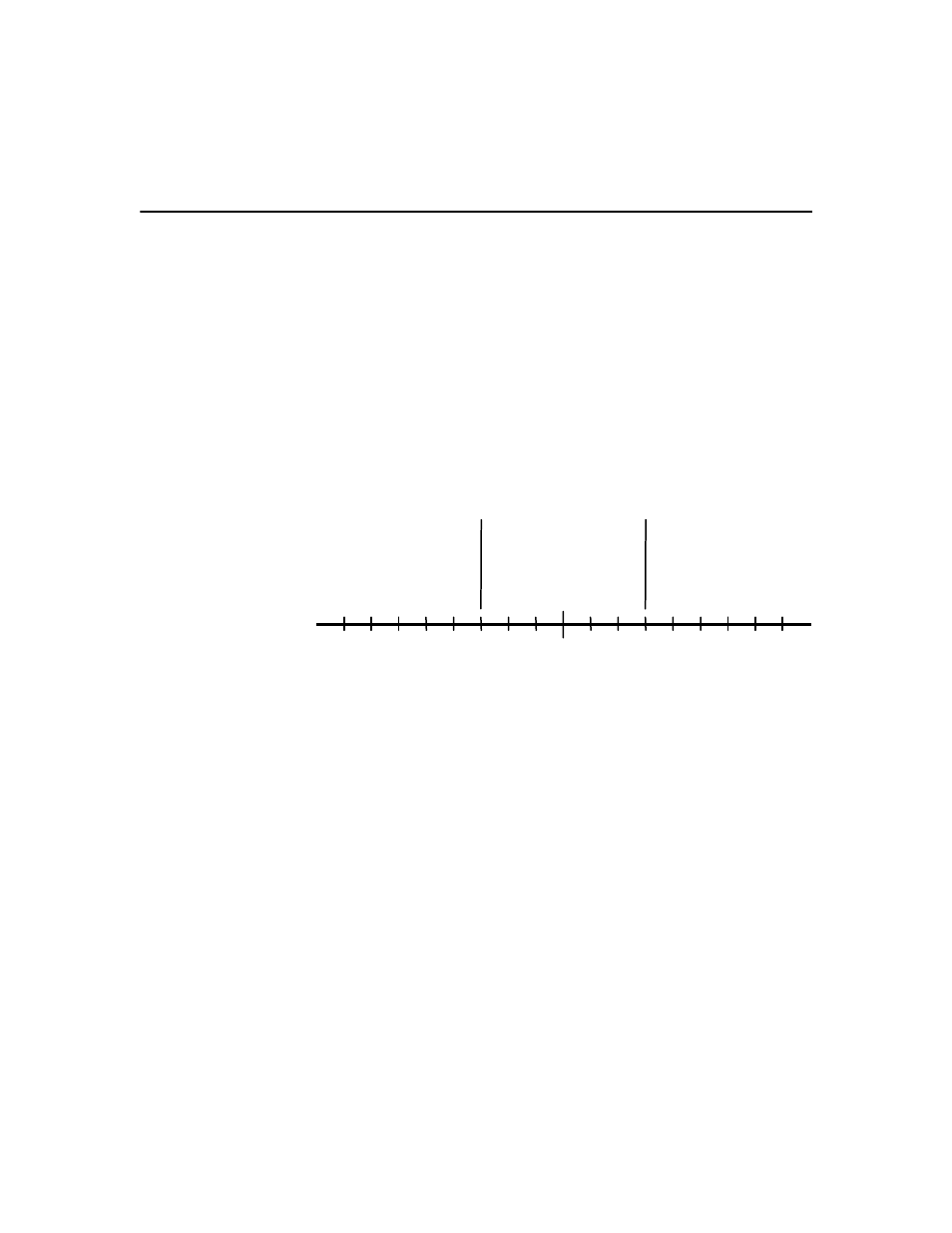

Position error tolerance is the amount of position error (±) the motion

controller tolerates without causing a position error fault.

See the Setup section of the Installation and Setup manual for your

motion controller for more information on position error tolerance.

Each physical axis of the motion controller can be configured to respond

to a position error fault in different ways. If position error fault action is

set to STOP MOTION, then, when the position error tolerance is

exceeded, the axis immediately decelerates to a stop without disabling

feedback or the drive enable output. If DISABLE DRIVE is selected,

when the position error tolerance is exceeded, axis feedback is

immediately disabled, the servo amplifier output is zeroed, and the

appropriate drive enable output is deactivated.

Position Error

Tolerance

Position Error

Position_error_fault

= 1

0.0

Position_error_fault

= 1

Position_error_fault

= 0

+

–