Delta Electronics Programmable Logic Controller DVP-PLC User Manual

Page 552

9 Application Instructions API 150-199

DVP-PLC Application Manual

9-80

7. When the 2-axis synchronous motion instruction is enabled, the start frequency and acceleration/deceleration

time in Y axis will be same as the settings in X axis.

8. The number of output pulses for the 2-axis motion shall not be the values within 1 ~ 59; otherwise the line drawn

will not be straight enough.

9. There is no limitation on the number of times using the instruction. However, assume CH1 or CH2 output is in use,

the 1

st

group X/Y axis will not be able to output. If CH3 or CH4 output is in use, the 2

nd

group X/Y axis will not be

able to output.

Program Example:

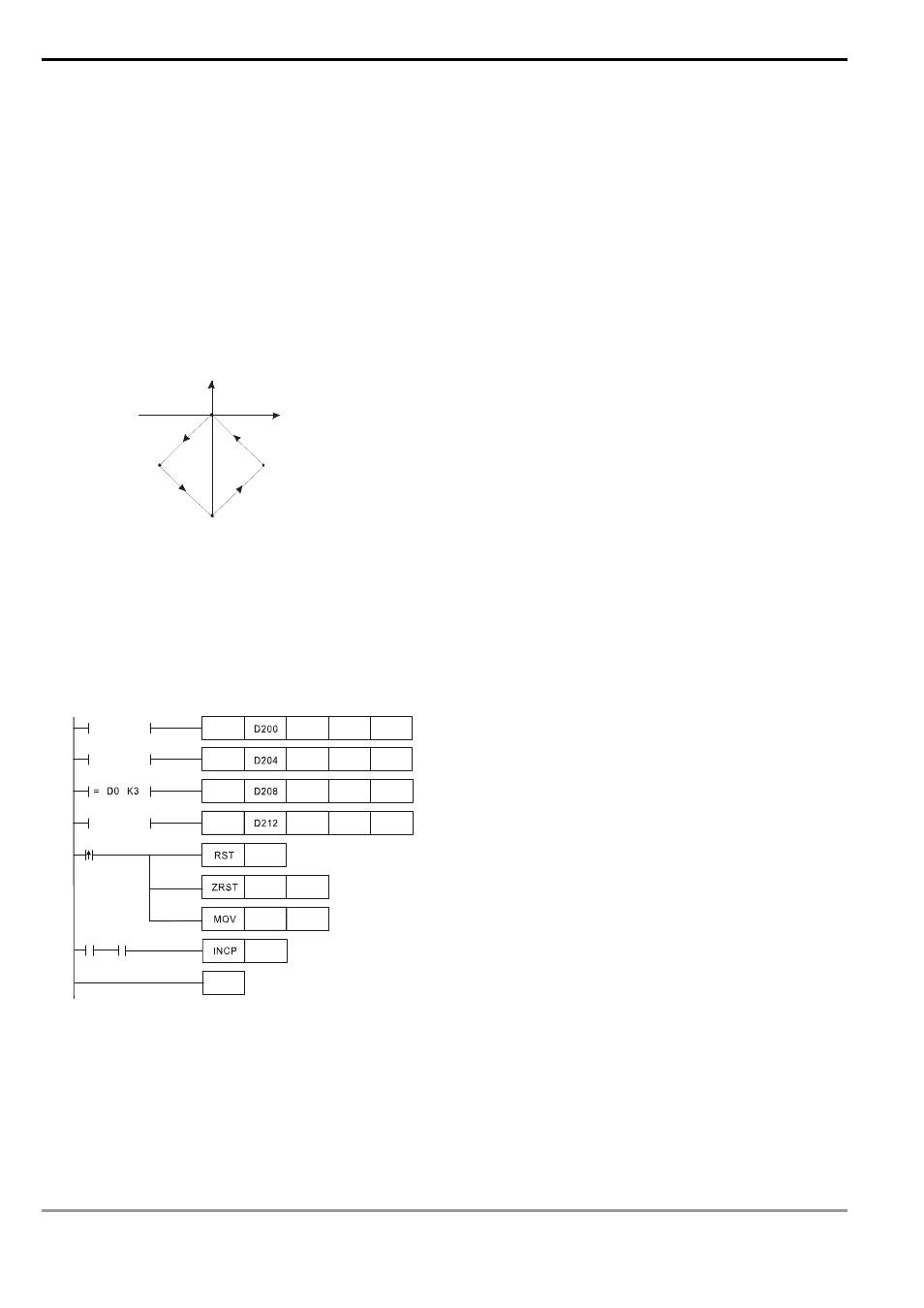

1. Draw a rhombus as the figure below.

(0, 0)

(-2700 0,-27 000)

(0, -5 5000)

(270 00,-27 000)

X

Y

2. Steps:

a) Set the four coordinates (0,0), (-27000, -27000), (0, -55000), (27000, -27000) (as the figure above). Place them in

the 32-bit (D200, D202), (D204, D206), (D208, D210), (D212, D214).

b) Write program codes as follows.

c) PLC RUN. Set M0 as On and start the 2-axis line drawing.

D214

DPPMA

D210

DPPMA

D206

DPPMA

K100000

D202

DPPMA

Y0

= D0 K1

= D0 K2

= D0 K4

K100000

Y0

K100000

Y0

K100000

Y0

M1029

END

M0

K1

D0

D0

M0

M1029

D1336

D1339

3. Motion

explanation:

When PLC RUN and M0 = On, PLC will start the first point-to-point motion by 100KHz. D0 will plus 1 whenever a

point-to-point motion is completed and the second point-to-point motion will start to execute automatically. The

same motion will keep executing until the fourth point-to-point motion is completed.