1 basic principles of plc ladder diagram – Delta Electronics Programmable Logic Controller DVP-PLC User Manual

Page 16

1 Basic Principles of PLC Ladder Diagram

DVP-PLC Application Manual

1-12

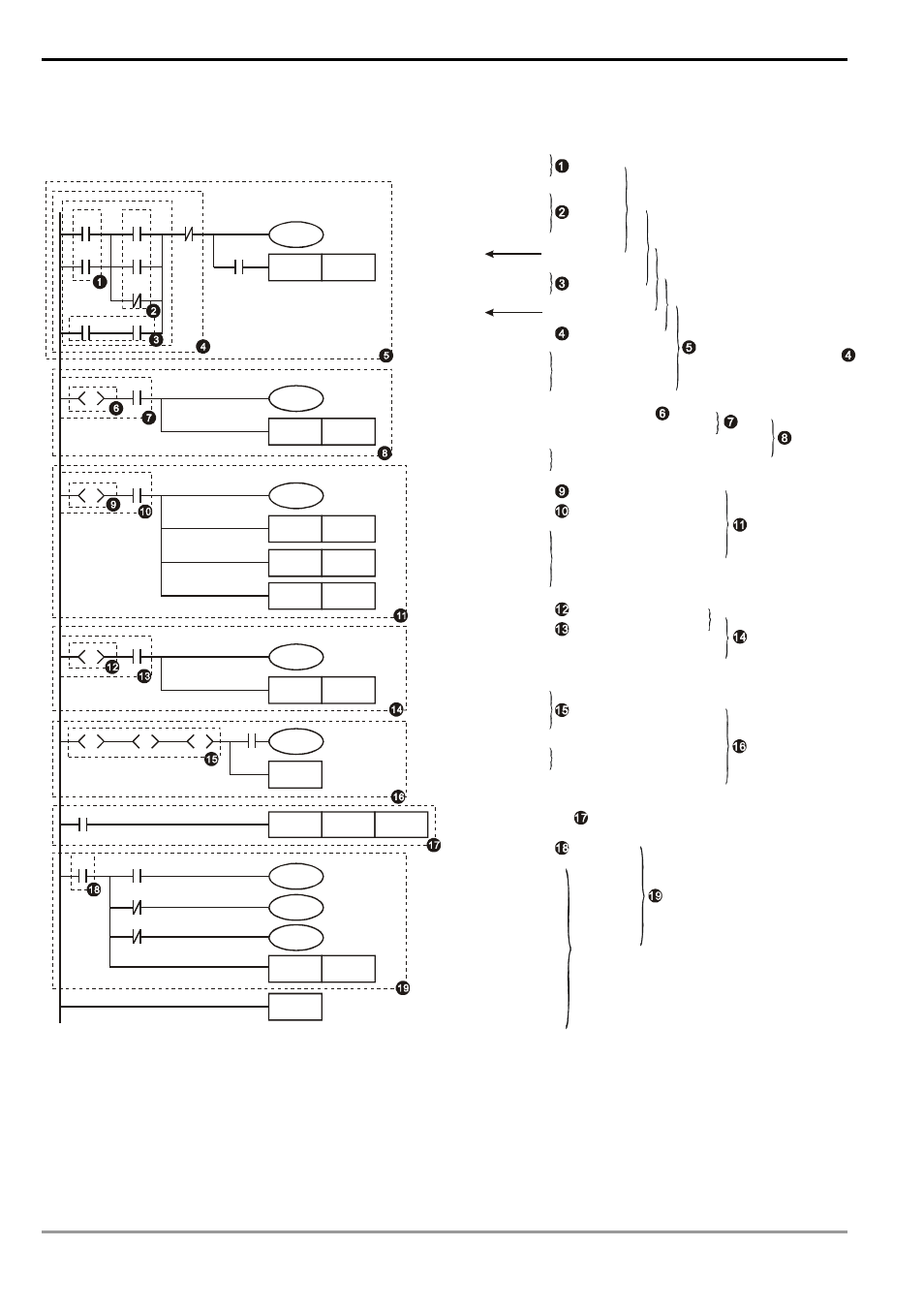

1.5 The Conversion of PLC Command and Each Diagram Structure

Ladder Diagram

X0

X2

X1

X1

M1

C0

Y0

SET

S0

M2

Y0

M0

X10

Y10

SET

S10

S0

S

X11

Y11

SET

S11

S10

S

SET

S12

SET

S13

X12

Y12

SET

S20

S11

S

X13

S0

RET

S20

S

S12

S

S13

S

X0

CNT

C0

K10

X1

M0

C0

X1

M2

RST

C0

M1

M2

END

LD X0

OR X1

LD X2

OR M0

ORI M1

ANB

LD M2

AND Y0

ORB

AN I X1

OUT Y0

AND C0

SET S0

STL S0

LD X10

OUT Y10

SET S10

STL S10

LD X11

OUT Y11

SET S11

SET S12

SET S13

STL S11

LD X12

OUT Y12

SET S20

STL S20

STL S12

STL S13

LD X13

OUT S0

RET

LD X0

CNT C0 K10

LD C0

MPS

AND X1

OUT M0

MRD

AN I X1

OUT M1

MPP

AN I M2

OUT M2

END

OR

block

ANI

Multiple

outputs

RST C0

OR

block

Series

connection blcok

AND

block

Parallel

connection block

The output will continue

following the status of

Step ladder Start

Status working item and

step point transfer

Withdraw S10 status

Withdraw X11 status

Status working item and

step point transfer

Withdraw S11 status

Withdraw X12 status

Status working item and

step point transfer

Bifurcation

convergence

End of step ladder

Status working item

and step point transfer

Return

Read C0

Multiple

outputs

End of program

Status S0 and X10 operation

Fuzzy Syntax

The correct ladder diagram analysis and combination should be conducted from up to down and left to right.

However, without adopting this principle, some instructions can make the same ladder diagram.