Delta Electronics DVP Series PLC DVP04TC-H2 User Manual

Warning, Introduction, Specifications

Warning

Please read this instruction sheet carefully before use.

Switch off the power before wiring.

DVP04TC-H2 is an OPEN-TYPE device and therefore should be installed in an enclosure free of airborne dust,

humidity, electric shock and vibration. The enclosure should prevent non-maintenance staff from operating the device

(e.g. key or specific tools are required to open the enclosure) in case danger and damages on the device may occur.

DO NOT connect input AC power supply to any of the I/O terminals; otherwise serious damage may occur. Check all

the wiring again before switching on the power.

DO NOT touch any terminal when the power is switched on.

Make sure the ground termnial

is correctly grounded in order to prevent electromagnetic interference.

Keep the wire as short as possible between RTD and PLC and the power wire as far away as possible from I/O wire

to prevent interference.

When setting the

thermocouple temperature sensor mode, please make sure that the setting of CR#1 is correct, or it will cause

serious errors.

Introduction

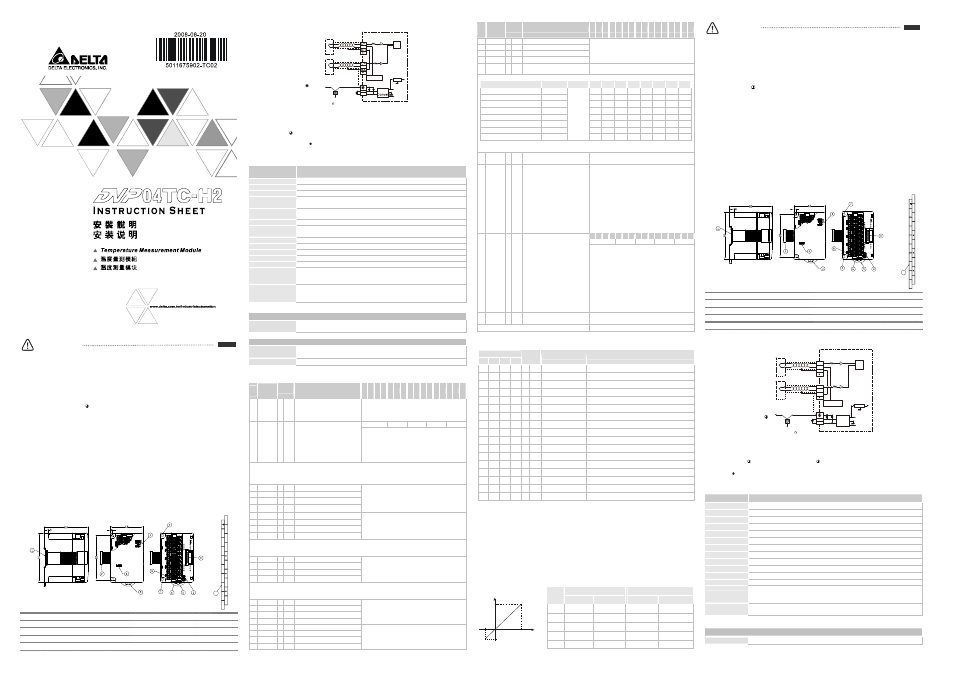

Model Explanation & Peripherals

Thank you for choosing Delta’s DVP series PLC. DVP04TC-H2 is able to receive 4 points of external

thermocouple temperature sensors (J-type, K-type, R-type, S-type, T-type) and convert them into 14-bit

digital signals. Besides, through FROM/TO instructions in DVP-EH2 MPU program, the data in

DVP04TC-H2 can be read or written. There are 49 16-bit control registers (CR) in DVP04TC-H2.

DVP04TC-H2 displays temperatures in Celsius (resolution: 0.1°C) and Fahrenheit (resolution: 0.18°F).

Product Profile (Indicators, Terminal Block, I/O Terminals)

Unit: mm

D

-

L

+

L

-

L

+

2

4

V

0

V

L

-

L

+

L

-

L

+

L

-

D

+

S

L

D

8

S

L

D

S

L

D

S

L

D

C

H

1

C

H

2

C

H

3

C

H

4

R

S

-4

8

5

1

DIN rail (35mm)

6

Terminals

2

Connection port for extension unit/module

7

Mounting hole

3

Model name

8

I/O terminals

4

POWER, ERROR, A/D indicator

9

Mounting port for extension unit/module

5

DIN rail clip

ENGLISH

External Wiring

CH1

CH4

DC/ DC

5V

AG

+15V

-15V

AG

24+

0V

L -

*2

*3

+

-

10 k

MUX

+

-

L -

Thermoc ouple

Thermoc ouple

Shielding

cable *1

Shielding

cable *1

Cold-Junction

Compensation

System

grounding

Terminal of

power module

Earth

(100 or less)

*1: The wiring used for analog input should adopts the connection cable or shielding cable of thermocouple temperature sensor

J-type / K-type / R-type / S-type / T-type and should be separated from other power cable or wirings that may cause interference.

The screw torque of the terminal should be 1.95 kg-cm (1.7 in-lbs).

*2: Terminal SLD is the ground location for noise suppression.

*3: Please connect the

terminal on both the power module and DVP04TC-H2 to the system earth point and ground the system

contact or connect it to the cover of power distribution cabinet.

Note:

DO NOT wire empty terminal . Use 60/75°C copper conductor only.

Specifications

Temperature

measurement module

Explanation

Power supply voltage

24V DC (20.4V DC ~ 28.8V DC) (-15% ~ +20%)

Analog output channel

4 channels/module

Applicable sensor types

J-type, K-type, R-type, S-type, T-type Floating thermocouple sensor

Range of input

temperature

See the table in Section

Range of digital

conversion

See the table in Section

Resolution

14 bits (0.1°C/0.18°F)

Overall accuracy

±0.5% when in full scale (25°C, 77°F)

±1% when in full scale within the range of 0 ~ 55°C, 32 ~ 131°F

Response time

200ms × the number of channels

Isolation

Isolation between digital area and analog area. No isolation among channels.

Digital data format

13 significant bits out of 16 bits are available; in 2’s complement

Average function

Yes; available for setting up in CR#2 ~ CR#5; range: K1 ~ K20

Self-diagnosis

Upper and lower bound detection/channel

Communication mode

(RS-485)

ASCII/RTU mode. Communication speed: 4,800/9,600/19,200/38,400/57,600 /115,200 bps.

ASCII data format: 7-bit, even bit, 1 stop bit (7, E, 1). RTU data format: 8-bit, even bit, 1 stop

bit (8, E, 1). RS-485 cannot be used when connected to PLC MPU.

When connected to

DVP-PLC MPU in series

The modules are numbered from 0 to 7 automatically by their distance from MPU. No. 0 is the

closest to MPU and No. 7 is the furthest. Maximum 8 modules are allowed to connect to MPU

and will not occupy any digital I/O points.

Other Specifications

Power supply

Max. rated power

consumption

24V DC (20.4V DC ~ 28.8V DC) (-15% ~ +20%), 2.5W supplied by external power.

Environment

Operation/storage

1. Operation: 0°C~ 55°C (Temperature), 50 ~ 95% (Humidity), pollution degree 2

2. Storage: -25°C~ 70°C (Temperature), 5 ~ 95%

(Humidity)

Vibration/shock immunity Standard: IEC61131-2, IEC 68-2-6 (TEST Fc)/IEC61131-2 & IEC 68-2-27 (TEST Ea)

Control Register

CR

#

RS-485

parameter

address

Latched

Register content

b15 b14 b13 b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 b0

#0

H’4096

○ R Model name

Set up by the system.

DVP04TC-H2 model code = H’6403.

You can read the model name from the program and see

if the extension module exists.

Reserved

CH4

CH3

CH2

CH1

#1

H’4097

○ R/W Thermocouple type

Take the setting of CH1 for example:

1. When (b2, b1, b0) is set as (0,0,0), choose J-type

2. When (b2, b1, b0) is set as (0,0,1), choose K-type

3. When (b2, b1, b0) is set as (0,1,0), choose R-type

4. When (b2, b1, b0) is set as (0,1,1), choose S-type

5. When (b2, b1, b0) is set as (1,0,0), choose T-type

CR#1: The working mode of the 4 channels in the sensors selected by the temperature measurement module. There are

2 modes (J-type and K-type) for each channel which can be set up separately. For example, if the user needs to set up

CH1: mode 0 (b2 ~ b0 = 100); CH2: mode 1 (b5 ~ b3 = 001); CH3: mode 0 (b8 ~ b6 = 000) and CH4: mode 1 (b11 ~ b9 =

001), CR#1 has to be set as H0208 and the higher bits (b12 ~ b15) have to be reserved. The default value = H’0000.

#2

H’4098

○ R/W CH1 average time

#3

H’4099

○ R/W CH2 average time

#4

H’409A

○ R/W CH3 average time

#5

H’409B

○ R/W CH4 average time

Range of settings in CH1 ~ CH4: K1 ~ K20. Default =K10.

Please note that when PLC MPU writes in the average

time by TO/DTO instruction, please use the rising/falling

edge contact detection instructions (LDP/LDF…) in case

you may not obtain the correct average temperature.

#6

H’409C

╳

R

Average °C temp. measured at CH1

#7

H’409D

╳

R

Average °C temp. measured at CH2

#8

H’409E

╳

R

Average °C temp. measured at CH3

#9

H’409F

╳

R

Average °C temp. measured at CH4

Average Celsius temperature measured at CH1 ~ CH4.

Unit: 0.1°C

CR#6 ~ CR#9: The average Celsius temperature measured at CH1 ~ CH4 obtained from the average time settings in

CR#2 ~ CR#5. For example, if the average time is set as 10, the content in CR#6 ~ CR#9 will be the average of the most

recent 10 temperature signals in Celsius at CH1 ~ CH4.

#10 H’40A0

╳

R

Average °F temp. measured at CH1

#11

H’40A1

╳

R

Average °F temp. measured at CH2

#12 H’40A2

╳

R

Average °F temp. measured at CH3

#13 H’40A3

╳

R

Average °F temp. measured at CH4

Average Fahrenheit temperature measured at CH1 ~

CH4.

Unit: 0.1°F

CR#10 ~ CR#13: The average Fahrenheit temperature measured at CH1 ~ CH4 obtained from the average time settings

in CR#2 ~ CR#5. For example, if the average time is set as 10, the content in CR#10 ~ CR#13 will be the average of the

most recent 10 temperature signals in Fahrenheit at CH1 ~ CH4.

#14 H’40A4

╳

R

Present °C temp. measured at CH1

#15 H’40A5

╳

R

Present °C temp. measured at CH2

#16 H’40A6

╳

R

Present °C temp. measured at CH3

#17 H’40A7

╳

R

Present °C temp. measured at CH4

Present Celsius temperature measured at CH1 ~ CH4.

Unit: 0.1°C

#19 H’40A9

╳

R

Present °F temp. measured at CH1

#20 H’40AA

╳

R

Present °F temp. measured at CH2

#21 H’40AB

╳

R

Present °F temp. measured at CH3

#22 H’40AC

╳

R

Present °F temp. measured at CH4

Present Fahrenheit temperature measured at CH1 ~ CH4.

Unit: 0.1°F

CR

#

RS-485

parameter

address

Latched

Register content

b15 b14 b13 b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 b0

#24 H’40AE

○ R/W OFFSET value of CH1

#25 H’40AF

○ R/W OFFSET value of CH2

#26 H’40B0

○ R/W OFFSET value of CH3

#27 H’40B1

○ R/W OFFSET value of CH4

Adjustable OFFSET settings at CH1 ~ CH4.

Range: -1,000 ~ +1,000

Default = K0

Unit: 0.1°C

#30 H’40B4

╳

R

Error status

Register for storing all error status.

See the table of error status for more information.

CR#30: Error status (see the table below)

Error status

Content

b15 ~ b8

b7

b6

b5

b4

b3

b2

b1

b0

Abnormal power supply

K1 (H’1)

0

0

0

0

0

0

0

1

Wiring to empty external contact K2 (H’2)

0

0

0

0

0

0

1

0

Incorrect mode setting

K4 (H’4)

0

0

0

0

0

1

0

0

OFFSET/GAIN error

K8 (H’8)

0

0

0

0

1

0

0

0

Hardware malfunction

K16 (H’10)

0

0

0

1

0

0

0

0

Abnormal digital range

K32 (H’20)

0

0

1

0

0

0

0

0

Incorrect average times setting

K64 (H’40)

0

1

0

0

0

0

0

0

Instruction error

K128 (H’80)

Reserved

1

0

0

0

0

0

0

0

Note:

Each error status is determined by the corresponding bit (b0 ~ b7) and there may be more than 2 errors occurring at the

same time. 0 = normal; 1 = error.

#31 H’40B5

○ R/W Communication address setting

For setting RS-485 communication address.

Range: 01 ~ 254, Default = K1.

#32 H’40B6

○ R/W

Communication speed (baud rate)

setting

For setting up communication speed: 4,800/9,600/19,200/

38,400/57,600/115,200 bps. ASCII data format: 7-bit, even

bit, 1 stop bit (7, E, 1). RTU data format: 8-bit, even bit, 1

stop bit (8, E, 1). Default: H’0002.

b0: 4,800 bps.

b1: 9,600 bps (default).

b2: 19,200 bps.

b3: 38,400 bps.

b4: 57,600 bps.

b5: 115,200 bps.

b14: High/low bit exchange of CRC checksum (only valid

in RTU mode)

b15: Switch between ASCII/RTU modes; 0 = ASCII mode

(default)

b15 b14 b13 b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 b0

ERR LED

CH4

CH3

CH2

CH1

#33 H’40B7

○ R/W Returning to default setting

Take the setting of CH1 for example:

1. b0 is reserved.

2. b1 is reserved.

3. When b2 is set as 1, all the settings will return to

default settings.

ERR LED definition: default of b12 ~ b15 = 1111

1. When b12 = 1, CH1 wiring to empty external contact,

ERR LED will flash.

2. When b13 = 1, CH2 wiring to empty external contact,

ERR LED will flash.

3. When b14 = 1, CH3 wiring to empty external contact,

ERR LED will flash.

4. When b15 = 1 CH2 wiring to empty external contact,

ERR LED will flash.

#34 H’40B8

○ R Firmware version

Displaying the current firmware version in hex; e.g.

version 1.0A is indicated as H’010A

#35 ~ #48

For system use

PID Control Registers

CR#

CH1 CH2 CH3 CH4

Latched

Register content

Explanation

#51

#71

#91 #111

○ R/W Temperature SV

Range: K-1,000 ~ K8,000. Default = K0.

#52

#72

#92 #112

○ R/W Sampling time (s)

Range: K1 ~ K30 (s). Default = K2.

#53

#73

#93 #113

○ R/W KP

Default = K121.

#54

#74

#94 #114

○ R/W KI

Integral constant, Default = K2,098.

#55

#75

#95 #115

○ R/W KD

Derivative constant, Default = K-29.

#56

#76

#96 #116

○ R/W Upper limit of I value

Range: K-32,760 ~ K32,760. Default = K0.

#57

#77

#97 #117

○ R/W Lower limit of I value

Range: K-32,760 ~ K32,760. Default = K0.

#58

#78

#98 #118

╳

R

I value

Current accumulated offset value. Default = K0.

#59

#79

#99 #119

○ R/W Heating/cooling control

0: Heater, 1: Cooler. Default = K0.

#60

#80 #100 #120

○ R/W Upper limit of output

Range: K-32,760 ~ K32,760. Default = K4,000.

#61

#81 #101 #121

○ R/W Lower limit of output

Range: K-32,760 ~ K32,760. Default = K0. .

#62

#82 #102 #122

╳

R

Output percentage (%)

Range: K0 ~ K1,000 (Unit: 0.1%). Default = K0.

#63

#83 #103 #123

╳

R

Output width (ms)

Width of control output, Unit: ms. Default = K0.

#64

#84 #104 #124

╳

R

Output cycle (ms)

Cycle of control output, Unit: ms. Default = K0.

#65

#85 #105 #125

╳

R

Output volume

Default = K0.

#66

#86 #106 #126

╳

R/W PID_Run/Stop

0: Stop, 1: Run. Default = K0.

#67

#87 #107 #127

╳

R/W Auto Tune

0: Disabled, 1: Auto-tuning. Default = K0.

※ CR#0 ~ CR#127: The corresponding parameter address H’4096 ~ H’4115 are for users to read/write data by

RS-485 communication. When using RS-485, the user has to separate the module with MPU first.

1. Modbus ASCII/RTU communication protocol: ASCII data format (7-bit, even bit, 1 stop bit (7, E, 1)); RTU

data format (8-bit, even bit, 1 stop bit (8, E, 1)).

2. Function: H’03 (read register data); H’06 (write 1 word datum into register); H’10 (write many word data

into register).

3. Latched CR should be written by RS-485 communication to stay latched. CR will not be latched if written

by MPU through TO/DTO instruction

4. Symbols:

○: Latched.

╳

: Non-latched. R: Able to read data by FROM instruction or RS-485

communication. W: Able to write data by TO instruction or RS-485 communication.

Temperature / Digital Curve

°C/°F Temperature Measurement Mode:

Max.

Min.

Digital output

Measured

temperature input

Min.

Max.

Range of input temperature

Range of digital conversion

Thermo

-couple

Min. (°C /

°F)

Max. (°C /

°F)

Min. (°C /

°F)

Max. (°C /

°F)

J type

-100°C / -148°F

700°C / 1,292°F

K-1,000 / K-1,480

K7,000 / K12,920

K type

-100°C / -148°F 1,000°C / 1,832°F K-1,000 / K-1,480

K10,000 / K18,320

R type

-10°C / -14°F

1,700°C / 3,092°F

K-100 / K-140

K17,000 / K30,920

S type

-10°C / -14°F

1,700°C / 3,092°F

K-100 / K-140

K17,000 / K30,920

T type

-100°C / -148°F

350°C / 662°F

K-1,000 / K-1,480

K3,500 / K6,620

注意事項

請在使用之前,詳細閱讀本使用說明書。

實施配線,務必關閉電源。

本機為開放型 (OPEN TYPE) 機殼,因此使用者使用本機時,必須將之安裝於具防塵、防潮及免於電擊

∕

衝

擊意外之外殼配線箱內。另必須具備保護措施(如:特殊之工具或鑰匙才可打開)防止非維護人員操作或意

外衝擊本體,造成危險及損壞。

交流輸入電源不可連接於輸入

∕

出信號端,否則可能造成嚴重的損壞,因此請在上電之前再次確認電源配線。

請勿在上電時觸摸任何端子或進行維修。

本體上之接地端子 務必正確的接地,可提高產品抗雜訊能力。

由測溫體到溫調本體的配線路請用最短距離配線,為了避免雜訊及誘導的影響儘可能將電源線和負載配線分

開。

感測器熱電耦型式設定,請檢查 CR#1,如設定錯誤會造成量測重大誤差。

產品簡介

說明及週邊裝置

謝謝您採用台達 DVP 系列產品。DVP04TC-H2 溫度量測模組可接受外部 4 點(熱電耦溫度感測器 J, K, R, S,

T

型),將之轉換成 14 位元之數位信號。透過 DVP-PLC EH2 主機程式以指令 FROM/TO 來讀寫模組內之

資料,模組內具有 49 個 CR (Control Register) 暫存器,每個暫存器有 16 bits。

使用者可選擇攝氏溫度或華氏溫度,攝氏溫度輸入解析度為 0.1

°C

,華氏溫度輸入解析度為 0.18

°F

。

產品外觀及各部介紹

尺寸單位:mm

D

-

L

+

L

-

L

+

2

4

V

0

V

L

-

L

+

L

-

L

+

L

-

D

+

S

L

D

8

S

L

D

S

L

D

S

L

D

C

H

1

C

H

2

C

H

3

C

H

4

R

S

-

4

8

5

1

DIN 軌糟 (35mm)

6

端子

2

擴充機/擴充模組連接口

7

固定孔

3

機種名稱

8

端子配置

4

電源、錯誤及轉換指示燈

9

擴充機/擴充模組連接座

5

DIN 軌固定扣

繁體中文

外部配線

熱電耦

CH1

CH4

DC/ DC

5V

AG

+15V

-15V

AG

24+

0V

L -

L+

轉換器

系統接地點

第三種接地

接地阻抗

以下

(100

)

接至電源模

隔離線 *1

*2

*3

隔離線 *1

熱電耦

+

-

10 k

MUX

冷接點補償

組之

端

+

-

L -

L+

SLD

SLD

註 1:使用於類比輸入的配線應採用 J / K / R / S / T 型熱電耦溫度感測器之連接線或隔離線且應與其他電源線或可能引起雜訊

之接線分開。端子鏍絲扭力為 1.95 kg-cm (1.7 in-lbs)。

註 2:如果雜訊過大請將 SLD 及接地端子連接。

註 3:請將電源模組之 端及 DVP04TC-H2 溫度量測模組之 端連接到系統接地點,再將系統接點作第三種接地或接到

配電箱之機殼上。

注意:空端子 請勿配線。只能使用 60/75°C 的銅導線。

規格

溫度量測模組

規格說明

電源電壓

24V DC (20.4V DC ~ 28.8V DC) (-15% ~ +20%)

類比訊號輸出通道

4

通道/台

適合感應器形式

J-type, K-type, R-type, S-type, T-type

非接地型熱電耦感測器

輸入溫度範圍

請參閱

附表

數位轉換範圍

請參閱

附表

解析度

14 bits (0.1°C/0.18°F)

總和精密度

±0.5%

在 (25°C, 77°F) 範圍內滿刻度時。±1% 在 (0 ~ 55°C, 32 ~ 131°F) 範圍內滿刻度時。

響應時間

200ms ×

通道數

隔離方式

數位區與類比區有隔離,通道間未隔離。

數位資料格式

16

位元二補數,有效位 13 bits。

平均功能

有(CR#2 ~ CR#5 可設定,範圍 K1 ~ K20)

自我診斷功能

上下極限偵測/通道

通訊模式 (RS-485)

包含 ASCII/RTU 模式,通訊速率可選 (4,800/9,600/19,200/38,400/57,600/115,200),ASCII 模式資

料格式固定為 7-bit、偶位元、1 stop bit (7, E, 1),RTU 模式資料格式固定為 8-bit、偶位元、1 stop bit

(8, E, 1)

。當與 PLC 主機串接時,RS-485 通訊無法使用。

與 DVP-PLC 主機

串接說明

模組編號以靠近主機之順序自動編號由 0 到 7,最大可連接 8 台且不佔用數位 I/O 點數

其他規格

電源規格

額定最大消耗功率

直流 24V DC (20.4V DC ~ 28.8V DC) (-15% ~ +20%), 2.5W, 由外部電源供應