1 basic principles of plc ladder diagram – Delta Electronics Programmable Logic Controller DVP-PLC User Manual

Page 22

1 Basic Principles of PLC Ladder Diagram

DVP-PLC Application Manual

1-18

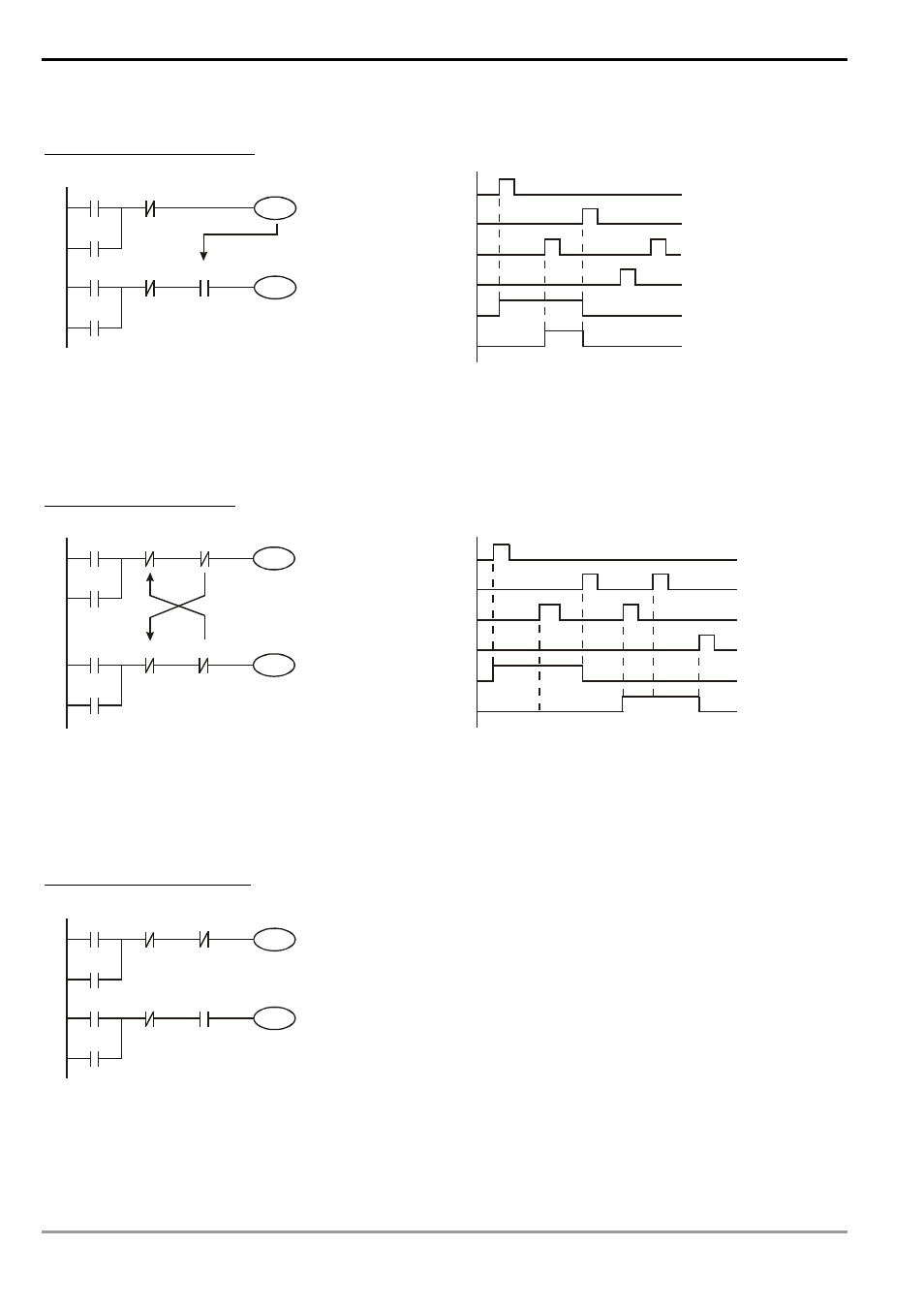

Frequently Used Control Circuit

Example 5: Conditional control

X3

Y1

X1

Y1

X4

Y2

X2

Y2

Y1

X1

X3

X2

X4

Y1

Y2

X1 and X3 enables and disables Y1; X2 and X4 enables and disables Y2, and all are latched. Due to that the

normally open contact of Y1 is connected to the circuit of Y2 in series, Y1 becomes an AND condition for Y2.

Therefore, only when Y1 is enabled can Y2 be enabled.

Example 6: Interlock control

X3

Y1

X1

Y1

X4

Y2

X2

Y2

Y1

Y2

X1

X3

X2

X4

Y1

Y2

Which of the X1 and X2 is first enabled decides either the corresponding output Y1 or Y2 will be enabled first.

Either Y1 or Y2 will be enabled at a time, i.e. Y1 and Y2 will not be enabled at the same time (the interlock). Even X1

and X2 are enabled at the same time, Y1 and Y2 will not be enabled at the same time due to that the ladder diagram

program is scanned from up to down. In this ladder diagram, Y1 will be enabled first.

Example 7: Sequential control

X3

Y1

X1

Y1

X4

Y2

X2

Y2

Y1

Y2

If we serially connect the normally closed contact

of Y2 in example 5 to the circuit of Y1 as an AND

condition for Y1 (as the diagram in the left hand side),

the circuit can not only make Y1 as the condition for Y2,

but also allow the stop of Y1 after Y2 is enabled.

Therefore, we can make Y1 and Y2 execute exactly the

sequential control.