Delta Electronics Brake Modules BUE Series User Manual

Bue series, Brake modules, Instruction sheet x

2007-11-07

5011642602-BU02

BUE Series

Brake Modules

Instruction Sheet

X

Preface

Congratulations on your purchase of DELTA’s brake module. BUE brake

units are applied to absorb the motor regenerative energy when 3-phase

induction motor stops by deceleration. With BUE brake unit, the

regenerative energy is dissipated in the brake resistors. To prevent

mechanical or human injury, please read this instruction sheet thoroughly

before wiring.

BUE brake units are suitable for VFD-E/VFD-EL Series. BUE brake units

need to be used in conjunction with BR series brake resistors to provide the

optimum brake characteristics.

BUE brake units (20015 and 40015) are approved by Underwriters

Laboratories, Inc. (UL) and Canadian Underwriters Laboratories (cUL). The

content of this instruction sheet may be revised without prior notice, please

consult our distributors or download the most updated version at

http://www.delta.com.tw/industrialautomation.

Y

Specifications

115/230V Series

460V Series

BUE-20015 BUE-20037 BUE-40015 BUE-40037

Max. Motor Capacity (KW)

1.5 3.7 1.5 3.7

Max. Peak Discharge

Current (A) 10%ED

3.6 16 1.8 8

Outpu

t

Rating

Brake Start-up

Voltage (DC)

328/345/362/380/400±3V 656/690/725/760/800±6V

Inpu

t

Rating

DC Voltage

200~400VDC 400~800VDC

Heat Sink Overheat

Temperature over +100

°C

Prote

cti

on

Power Charge

Display

Blackout until bus (+~-) voltage below 50VDC

Installation Location

Indoor (no corrosive gases, metallic dust)

Operating

Temperature

-10℃~+50℃

Storage Temperature

-20℃~+60℃

Humidity

90%R.H., Non-condensing

Environmen

t

Vibration

9.8m/s

2

(1G) under 20Hz

2m/s

2

(0.2G) at 20~50Hz

Mechanical Configuration

Wall-mounted enclosed type IP20

Z

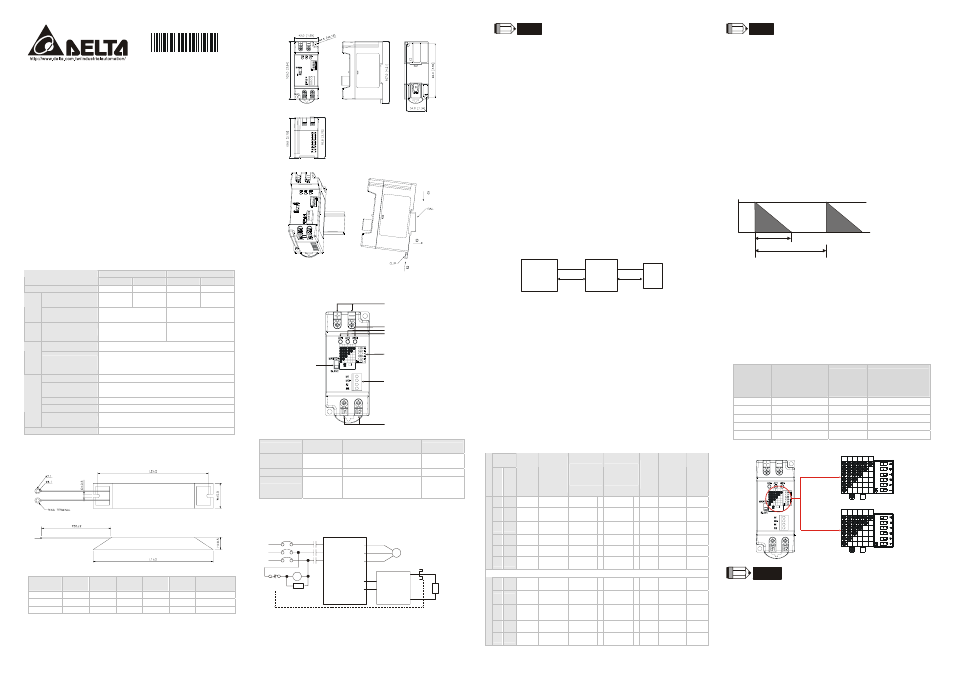

Dimensions and Installations

3.1 Brake resistor

TYPE

L1

L2

H

D

W

MAX.

WEIGHT(g)

BR080W200

140 125 20 5.3 60 160

BR080W750

140 125 20 5.3 60 160

BR300W400

215 200 30 5.3 60 750

3.2 Brake unit

3.3 DIN Rail Installation

[

Outline and Wire Gauge

4.1 Outline

Slave output/input

Terminals

220

240230

210200190

OFF

ON

Power lamp

Brake lamp

Fault lamp

MASTER/SLAVE

Switch

Power Input

Terminal

Brake Resistor Terminal

Dip Switch

for Input Voltage Setting

M1 SLAVE output signal +

M2

S1

S2

:

:

:

:

SLAVE output signal -

SLAVE input signal +

SLAVE input signal -

4.2 Wire Gauge for Terminals

Circuit

Terminal

Symbol

Wire Gauge

AWG/mm

2

Terminal

Power Input

Circuit

+(P), -(N)

20~22AWG/0.5~0.3mm

2

M4

Screw

Brake Resistor

B1, B2

20~22AWG/0.5~0.3mm

2

M4

Screw

SLAVE Circuit

M1, M2

S1, S2

24AWG/0.2mm

2

M1, M2, S1, S2 with shielded

wires

M2 Screw

\

Basic Wiring Diagram

R/L1

S/L2

T/L3

NFB

MC

VFD-E/VFD-EL

Series

BUE

MOTOR

O.L.

U/T1

V/T2

W/T3

+/B1 P

- N

( )

( )

B1

B2

SA

R/L1

S/L2

T/L3

MC

IM

BR

O.L.

Thermal

Overload

Relay

Surge

Absorber

Thermal Overload

Relay

Brake Resistor

Brake

Unit

+ P

- N

( )

( )

Note1: When the AC drive uses with DC reactor, please refer to the wiring diagram in the

VFD-E/EL user manual for wiring terminal +(P) of brake unit.

Note2:

wire terminal -(N) to neutral point of power system.

DO NOT

NOTE

For safety consideration, install an overload relay between the

brake unit and the brake resistor. In conjunction with the magnetic

contactor (MC) prior to the drive, it can perform complete protection

against abnormality.

The purpose of installing the thermal overload relay is to protect the

brake resistor from damage due to frequent brake, or due to brake

unit keeping operating resulted from unusual high input voltage.

Under such circumstance, just turn off the power to avoid

damaging the brake resistor.

Please refer to “7 Brake Resistor/Units for the AC Drives” for the

specification of the thermal overload relay.

]

Wiring Warnings

Do not proceed with wiring while power is applied to the circuit.

The wiring gauge and distance must comply with the local

regulations.

The +(P), -(N) terminals of the AC motor drive (VFD-E/VFD-EL

Series), connected to the brake unit (BUE), must be confirmed for

correct polarity lest the drive and the brake unit be damaged when

power on.

When the brake unit performs brake, the wires connected to +(P),

-(N), B1 and B2 would generate a powerful electromagnetic field

for a moment due to high current passing through. These wires

should be wired separately from other low voltage control circuits

lest they make interference or mis-operation

Wiring distance

VFD-E/VFD-EL

series

0.2~1.5kW

115V/230/460V

Max. 2M

Max. 1M

BR

BUE-

20015

20037

40015

40037

AC Motor Drive

Brake Unit

Brake Resistor

Inflammable solids, gases or liquids must be avoided at the location

where the brake resistor is installed. The brake resistor had better

be installed in individual metallic box with forced air-cooling.

Connect the ground terminal to the Earth Ground. The ground lead

must be at least the same gauge wire as leads +(P), -(N).

Please install the brake resistor with forced air-cooling or the

equivalent when frequent deceleration brake is performed (over

10%ED).

To avoid personal injury, do not connect/disconnect wires or

regulate the setting of the brake unit while power on. Do not touch

the terminals of related wiring and any component on PCB lest

users be damaged by extreme dangerous DC high voltage

We suggest to use ring terminals for main circuit wiring. Make sure

the terminals are fastened before power on.

^

Brake Resistors/Units for Delta VFD

AC Motor Drives Series

Applicable

Motor

Vo

lta

ge

HP kW

Full-load

output

torque

KG-M

Equivalent

brake

resistor for

each AC

drive

Brake Unit

Model and

Quantity

Brake Resistor

Model and

Quantity

Brake

Torque

10%

ED%

Min.

Equivalent

Resistor

Value for

Each AC

Drive

Typical

Thermal

Overload

Relay

Value

1/4 0.2

0.110

200W 250Ω

BUE20015 1

BR200W250

1

320

200Ω 2A

1/2 0.4

0.216

200W 250Ω

BUE20015 1

BR200W250

1

170

100Ω 3A

1 0.75 0.427

200W 150Ω

BUE20015 1

BR200W150

1

140

80Ω 4A

2

1.5

0.849

300W100Ω

BUE20015 1

BR300W100

1

107

80Ω 4A

3

2.2

1.262

600W 50Ω

BUE20037 1

BR300W100

2

150

25Ω 12A

115/230V

Serie

s

5

3.7

2.080

900W 30Ω

BUE20037 1

-

-

150

25Ω 12A

1/2 0.4

0.216

300W 400Ω

BUE40015 1

BR300W400

1

400

400Ω 2A

1 0.75 0.427

300W 400Ω

BUE40015 1

BR300W400

1

200

200Ω 3A

2

1.5

0.849

400W 300Ω

BUE40015 1

BR200W150

1

140

160Ω 4A

3

2.2

1.262

300W 400Ω

BUE40037 1

BR300W400

2

150

100Ω 6A

460V

5

3.7

2.080

900W 120Ω

BUE40037 1

-

-

150

100Ω 6A

NOTE

“-“ means no Delta product. Please use the brake unit according to

the Equivalent Resistor Value.

The cycle time of brake usage ED% in the above table is 10

seconds.

For the detail applicable models, refer to the following list:

A. BUE20015 is used for

VFD002E11A/11P/11C/21A/21P/21C/23A/23P/23C,

VFD004E11A/11P/11C/21A/21P/21C/23A/23P/23C,

VFD007E21A/21P/21C/23A/23P/23C, VD015E23A/23P/23C,

VFD002EL11A/21A/23A, VFD004EL11A/21A/23A,

VFD007EL11A/21A/23A, VFD015EL21A/23A

B. BUE20037 is used for VFD022EL21A/23A, VFD037EL23A

C. BUE40015 is used for VFD004E43A/43P/43C,

VFD007E43A/43P/43C, VFD015E43A/43C, VFD004EL43A,

VFD007EL43A, VFD015EL43A

D. BUE40037 is used for VFD022EL43A, VFD037EL43A

_

Definition for the Brake Usage ED%

100%

T0

T1

Brake Time

Cycle Time

ED% = T1/T0x100(%)

The definition of the brake usage ED(%) is to assure having enough time

for the brake unit and brake resistor to dissipate the heat generated by

brake. When the brake resistor heats up, the resistance would increase

with temperature, and brake torque would decrease accordingly.

`

The Voltage Settings

The power source of the brake unit is the DC power from the + (P) and - (N)

terminals of the AC motor drive. Therefore, it is an important step to set the

voltage by the input voltage of the AC motor drive before operation. This

setting will affect the voltage level of the brake unit.

Table 1: The voltage selection and operation level of the PN DC voltage

115V/230V

Model

AC Power

Voltage

Brake Start-up

voltage

DC Bus (+(P), -(N))

Voltage

460V Model

AC Power

Voltage

Brake Start-up voltage

DC Bus (+(P), -(N))

Voltage

190Vac 330Vdc 380Vac 660Vdc

200Vac 345Vdc 400Vac 690Vdc

210Vac 360Vdc 420Vac 725Vdc

220Vac 380Vdc 440Vac 760Vdc

230Vac 400Vdc 460Vac 800Vdc

NOTE: Input Power With Tolerance ±10%

220

24 02 30

21 02 0019 0

OFF

ON

220

240230

210200190

OFF

ON

440

480460

420400380

OFF

ON

For BUE-20015 Series/

BUE-20037 Series

Factory setting: 190V

For BUE-40015 Series/

BUE-40037 Series

Factory setting: 380V

NOTE

Before setting the voltage, make sure the power has been turned

off.

Please set power voltage as the possible highest voltage for

unstable power system. Take 380VAC power system for example.

If the voltage may be up to 410VAC, 415VAC should be selected.

For VFD-E/VFD-EL Series, please set parameter Pr06.00=0 (Over

Voltage Stall Prevention) to disable over-voltage stall prevention, to

ensure stable deceleration characteristic.