Delta Electronics Programmable Logic Controller DVP-PLC User Manual

Page 392

7 Application Instructions API 50-99

D V P - P L C A P P L I C AT I O N M A N U A L

7-108

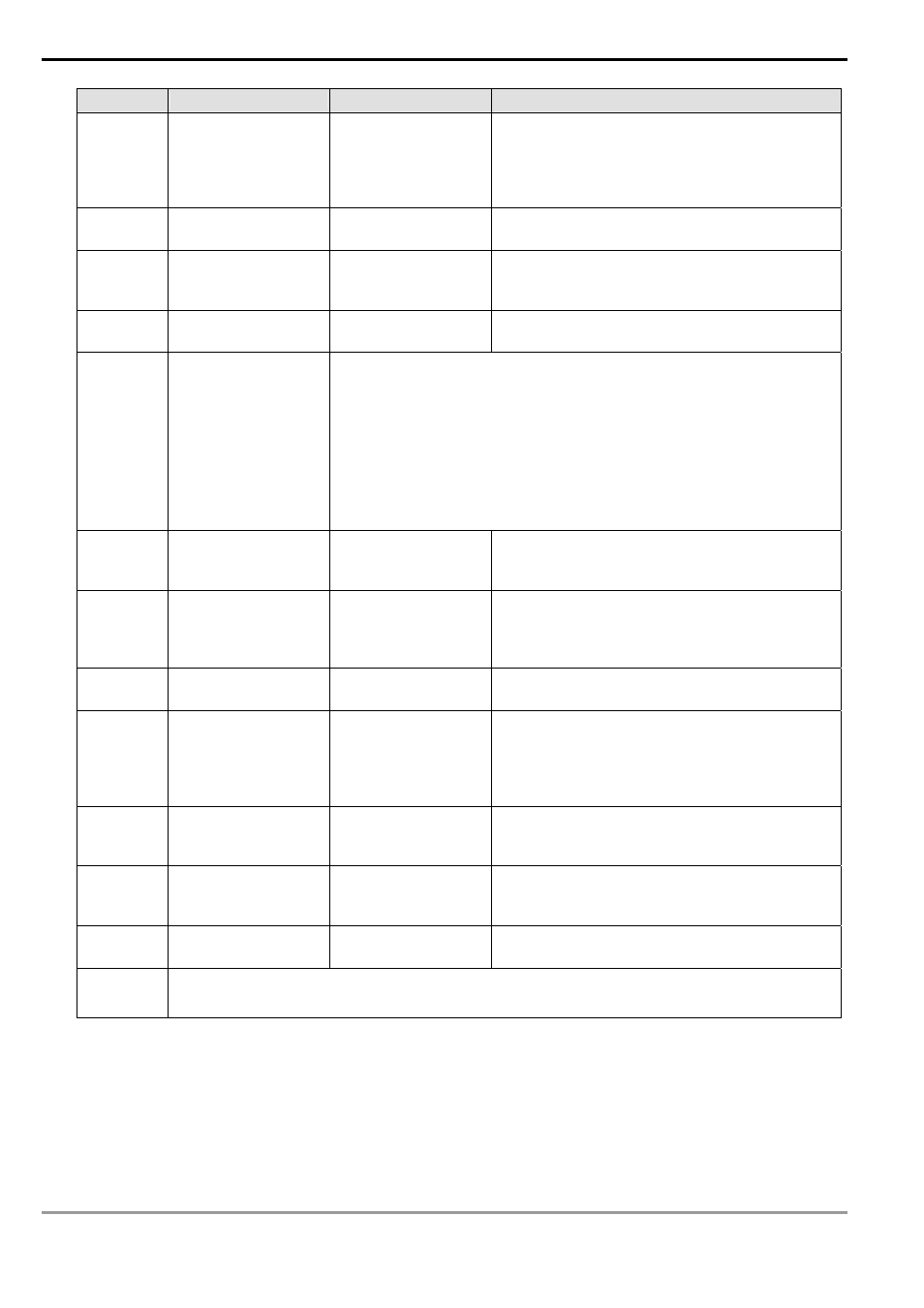

Device No.

Function

Setup Range

Explanation

S

3

:

Sampling time (T

S

)

(unit: 10ms)

1 ~ 2,000

(unit: 10ms)

If T

S

is less than 1 program scan time, PID

instruction will be executed for 1 program scan

time. If T

S

= 0, PID instruction will not be enabled.

The minimum T

S

has to be longer than the

program scan time.

S

3

+1:

Proportional gain (K

P

) 0 ~ 30,000 (%)

The magnified error proportional value between

SV – PV.

S

3

+2:

Integral gain (K

I

)

0 ~ 30,000 (%)

The magnified proportional value of every

sampling time unit × the accumulated value of

the error.

S

3

+3:

Differential gain (K

D

)

-30,000 ~ 30,000 (%)

The magnified proportional value of the varied

error in every samping timme unit.

S

3

+4:

Control direction

(DIR)

0: automatic control

1: forward control (E = SV - PV)

2: inverse control (E = PV - SV)

3: Auto-tuning of parameter exclusively for the temperature control. The

device will automatically become K4 when the auto-tuning is

completed and be filled in with the appropriate parameter K

P

, K

I

and

K

D

(not avaliable in the 32-bit instruction).

4: Exclusively for the adjusted temperature control (not avaliable in the

32-bit instruction).

S

3

+5:

The range that error

value (E) doesn’t

work

0 ~ 32,767

E = the error of SV – PV. When S

3

+5 = K0, the

function will not be enabled, e.g. when S

3

+5 is

set as 5, MV of E between -5 and 5 will be 0.

S

3

+6:

Upper bound of output

value (MV)

-32,768 ~ 32,767

Ex: if S

3

+6 is set as 1,000, the output will be

1,000 when MV is bigger than 1,000. S

3

+6 has

to be bigger or equal S

3

+7; otherwise the upper

bound and lower bound will switch.

S

3

+7:

Lower bound of output

value (MV)

-32,768 ~ 32,767

Ex: if S

3

+7 is set as -1,000, the output will be

-1,000 when MV is smaller than -1,000.

S

3

+8:

Upper bound of

integral value

-32,768~32,767

Ex: if S

3

+8 is set as 1,000, the output will be

1,000 when the integral value is bigger than

1,000 and the integration will stop. S

3

+8 has to

be bigger or equal S

3

+9; otherwier the upper

bound and lower bound will switch.

S

3

+9:

Lower bound of

integral value

-32,768 ~ 32,767

Ex: if S

3

+9 is set as -1,000, the output will be

-1,000 when the integral value is smaller than

-1,000 and the integration will stop.

S

3

+10,11:

Accumulated integral

value

32-bit floating point

The accumulated integral value is only for

reference. You can still clear or modify it (in

32-bit floating point) according to your need.

S

3

+12:

The previous PV

-

The previous PV is only for reference. You can

still modify it according to your need.

S

3

+13:

~

S

3

+19:

For system use only.

5. When parameter setting exceeds its range, the upper bound and lower bound will become the setting value.

However, if the motion direction (DIR) exceeds the range, it will be set to 0.

6. PID instruction can be used in interruption subroutines, step points and CJ instruction.

7. The maximum error of sampling time T

S

= - (1 scan time + 1ms) ~ + (1 scan time). When the error affects the

output, please fix the scan time or execute PID instruction in the interruption subroutine of the timer.

8. PV of PID instruction has to be stable before the execution of PID instruction. If you are to extract the input value