Delta Electronics Programmable Logic Controller DVP-PLC User Manual

Page 399

7 Application Instructions API 50-99

D V P - P L C A P P L I C AT I O N M A N U A L

7 - 115

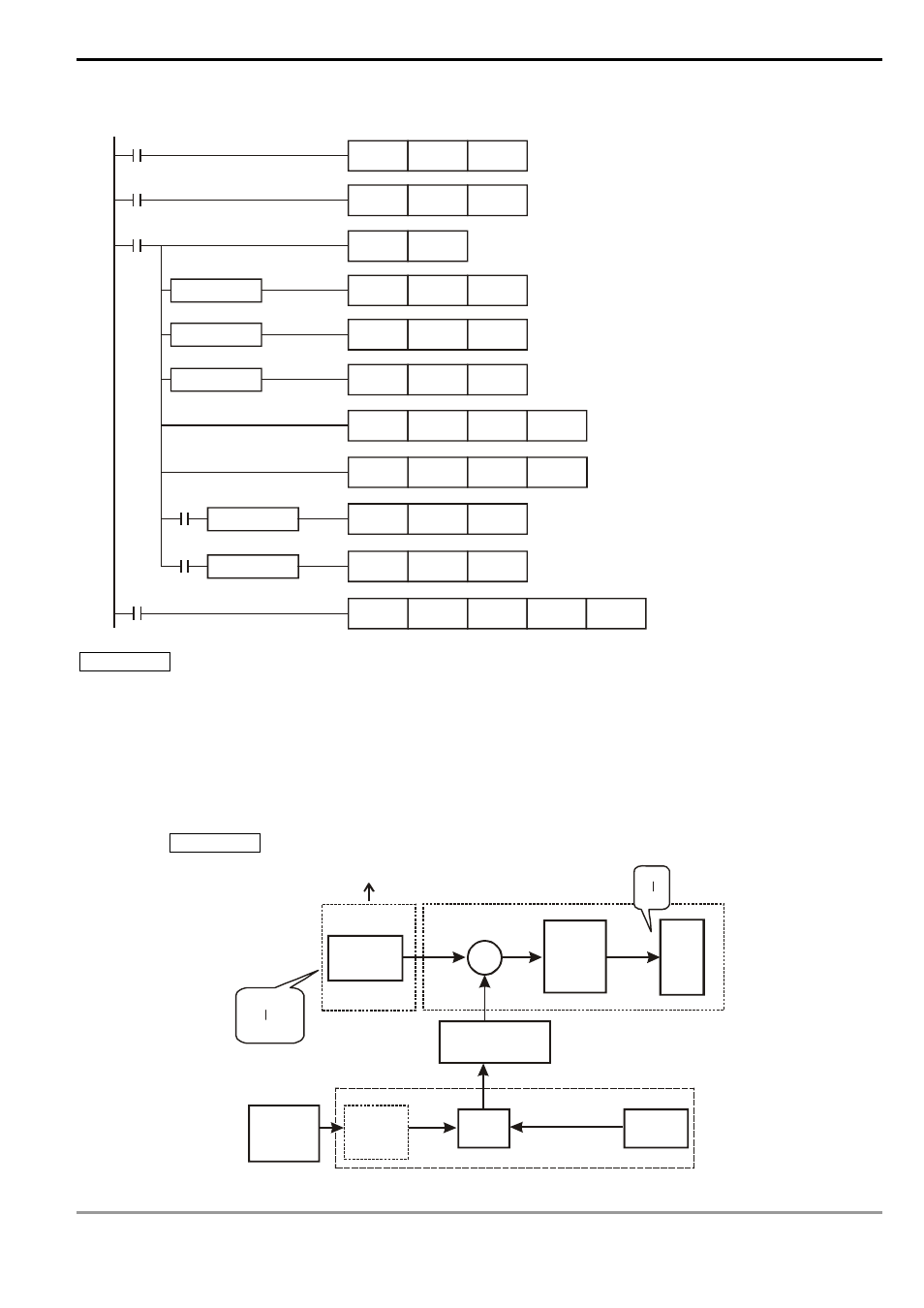

The example program of the instruction delay:

M1002

MOV

K10

D3

M0

TMR

T0

D3

T0

RST

T0

MOV

K50

D2

D1

D0

>

MOV

K-50

D2

D1

D0

<

MOV

K0

D2

D1

D0

=

ADD

D2

D1

D1

M10

CMP

D2

K0

M10

D0

D1

<

MOV

D0

D1

M12

D0

D1

>

MOV

D0

D1

M0

PID

D1

D1116

D10

D5

Application 2 Speed control system and pressure control system work individually (use diagram of Example 2).

Purpose: After the speed control operates in open loop for a period of time, adding into it the pressure control system

(PID instruction) for close loop control.

Explanation: Since the speed and pressure control systems are not interrelated, we have to structure a open loop for

speed control first following by a close loop pressure control. If you fear that the control instruction of the

pressure control system changes too fast, you can consider to add the instruction delay illustrated in

Application 1 into the control. See the control diagram below.

D40

0

255

0rpm

3,000rpm

D30

D32

D1116

D31

+

+

M3

PID

PV

MV

D5

D1

SV

D0

D1110

Speed

instruction

M2 = On

Speed

converted

to

voltage

AC

motor

drive

MV converted to

accel/decel value

M0 = On

Pressure

instruction

Delay

(optional)

M1 = On

Pressure

meter