Delta Electronics Programmable Logic Controller DVP-PLC User Manual

Page 396

7 Application Instructions API 50-99

D V P - P L C A P P L I C AT I O N M A N U A L

7-112

b) PID instruction can only be used once in ES/EX/SS (v5.6 and below) series MPU. There is no limitation on

the times of using PID instruction in ES/EX/SS (v5.7 and above) series and SA/SX/SC/EH/EH2/SV series

MPU.

c) S

3

+ 3 of ES/EX/SS (v5.7 and below), SA/SX/SC (v1.1 and below) and EH (v1.0 and below) series MPU can

only be the value within 0 ~ 30,000.

d) There are a lot of circumstances where PID instruction can be applied; therefore, please choose the control

functions appropriately. For example, when you select parameter auto-tuning for the temperature (S

3

+ 4 =

K3), you cannot use it in a motor control environment in case improper control may occur.

e) When you adjust the three main parameters, K

P

, K

I

and K

D

(S

3

+ 4 = K0 ~ K2), you have to adjust K

P

first

(according to your experiences) and set K

I

and K

D

as 0. When you can roughly handle the control, you then

adjust K

I

(increasingly) and K

D

(increasingly) (see example 4 below for how to adjust). K

P

= 100 refers to

100%, i.e. the gain of the error is 1. K

P

< 100% will decrease the error and K

P

> 100% will increase the error.

f) When you select the parameter exclusively for temperature control (S

3

+ 4 = K3, K4), it is suggested that you

store the parameter in D register in the latched area in case the automatically adjusted parameter will

disappear after the power is cut off. There is no guarantee that the adjusted parameter is suitable for every

control. Therefore, you can modify the adjusted parameter according to your actual need, but it is suggested

that you modify only K

I

or K

D

.

g) PID instruction can to work with many parameters; therefore please do not randomly modify the parameters

in case the control cannot be executed normally.

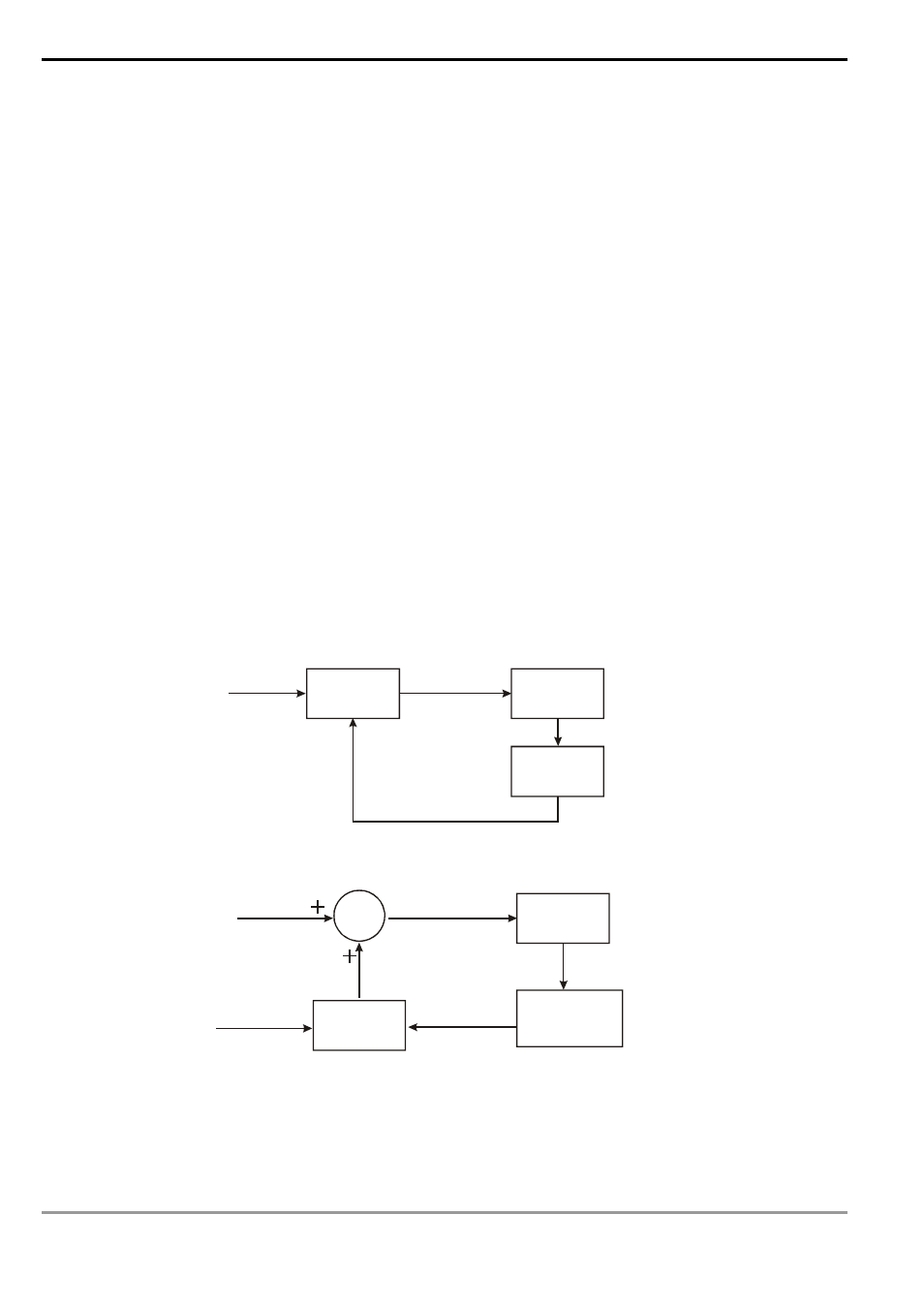

Example 1:

Diagram of using PID instruction in position control (S

3

+ 4 = 0)

PID

MV

Encoder

PV

Position instruction

(SV)

Controlled

device

Example 2:

Diagram of using PID instruction with AC motor drive on the control (S

3

+ 4 = 0)

PID

S+MV

Speed instruction (S)

Acceleration/deceleration

instruction (SV)

Acceleration/deceleration

output (MV)

Actual acceleration/

deceleration speed

(PV = S - P)

AC motor

drive

Speed

detection

device (P)