Configuration settings, Onfiguration, Ettings – Ag Leader InSight Ver.8.0 Users Manual User Manual

Page 184

170

C

ONFIGURATION

S

ETTINGS

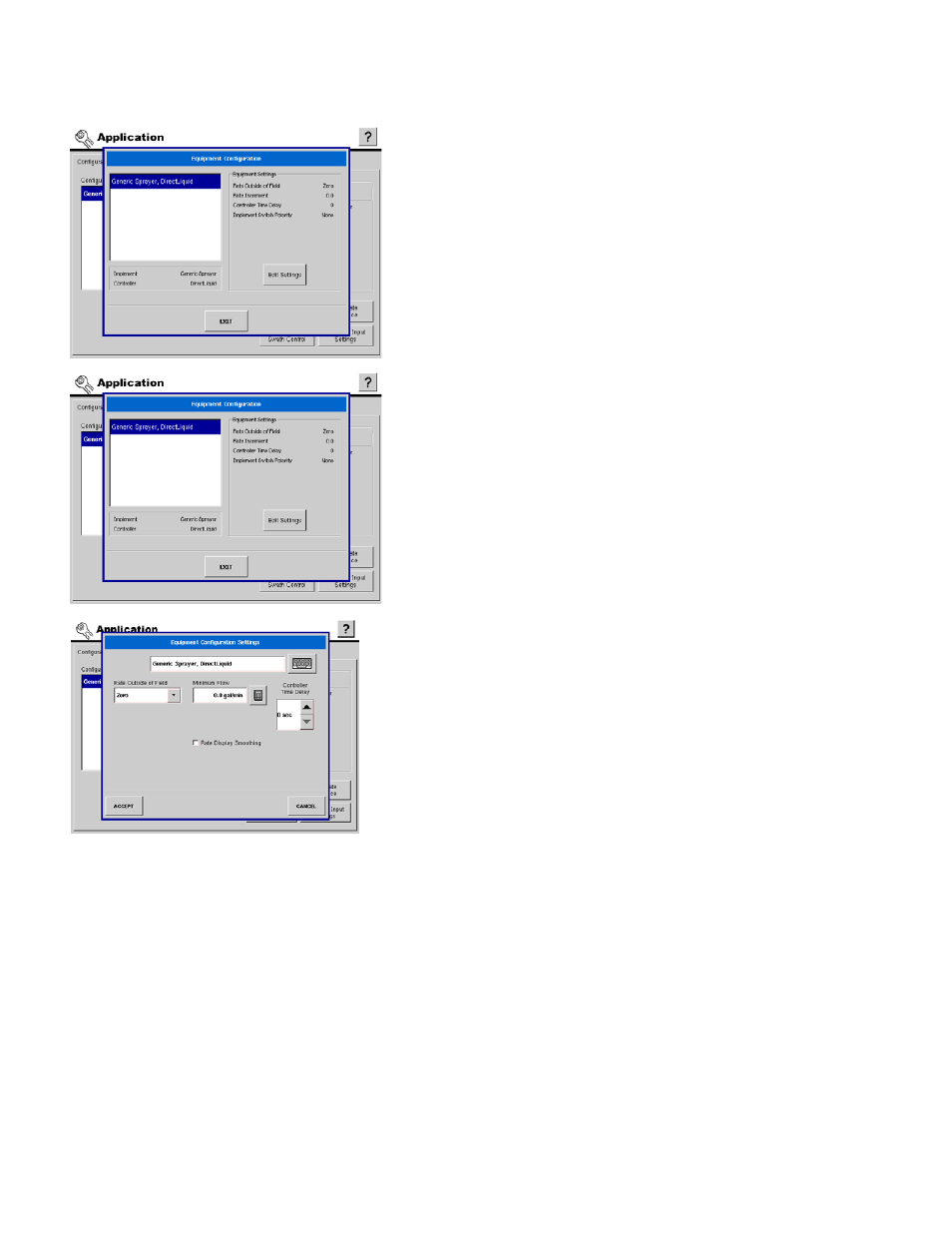

Select a Configuration from the list and press the

Configuration Settings button to access the related settings.

These settings are directly related to that specific

combination of Vehicle, Implement, and Controller.

The Equipment Configuration window, shown at left, will

display after selecting an operating configuration and

pressing the Configuration Settings button.

Implement and controller name for the configuration are

displayed at the lower left on the dialog box. Settings related

to controller operation for the configuration are displayed on

the right.

Press Edit Settings to display detailed information or edit any

of these settings.

The configuration name can be changed by pressing the on-

screen keyboard screen.

The Rate Outside of Field selection as defined in the table below

determines product control channel behavior when the field

boundary is exited.

• Zero = Product application will turn off.

• Last Good = Product application will continue at the last value used

by the control system.

• Rx Default = Product will be applied at the default rate setting

The Minimum Flow setting is used to maintain a consistent spray pattern. The display will not allow

flow to drop below the entered setting. Set to flow at the lowest operating pressure for the selected spray

tips with all sections on. When spraying with one or more boom sections off, the display automatically

reduces the minimum flow setting according to the reduced spray width. To adjust this setting, select the

keyboard button and enter the desired numeric value.

The Rate Display Smoothing setting determines how the feedback from the control channel rate sensor

will be displayed on the run screen. When de-selected, the display will show raw feedback from the rate

sensor. When checked, the display will show target rate when the application rate is within 10% of the

target rate setting.

The Controller Time Delay setting compensates for any latency in the control system when changing

between different product flow rates during variable rate application. The typical setting range for this is

0 - 1 seconds.