Segment generator diagram – MTS Multipurpose Elite User Manual

Page 425

Monitor Continuous

Continuous monitor watches specified variables for span and setpoint values and sets them in the controller

whenever the variable values change. The activity runs until the parallel activity in which it is contained is

closed from another branch.

For example, use the Continuous monitor option in fatigue crack growth applications. Crack length updates

with each cycle. Span and setpoint variables are also calculated, which means that new values are sent

to the controller on every cycle.

Maintain command to prevent movement

When you enable the Maintain command option, the command signal holds steady while the span and

setpoint values are adjusted. The Maintain command feature is particularly useful when an operator needs

to recover setpoint and span values from an unusual circumstance, such as a system crash occurring

while a test was running.

For More Information

Task

Setting Initial (One Time) Span and Setpoint Values

(p. 428)

Setting Continuous Span and Setpoint Values

(p. 429)

Maintaining Command to Prevent Movement

(p. 429)

Reference

(p. 425)

Set Span and Setpoint Activity Properties

(p. 426)

Example: Setting Span and Setpoint

(p. 430)

Example: Maintain Command Test Design

(p. 431)

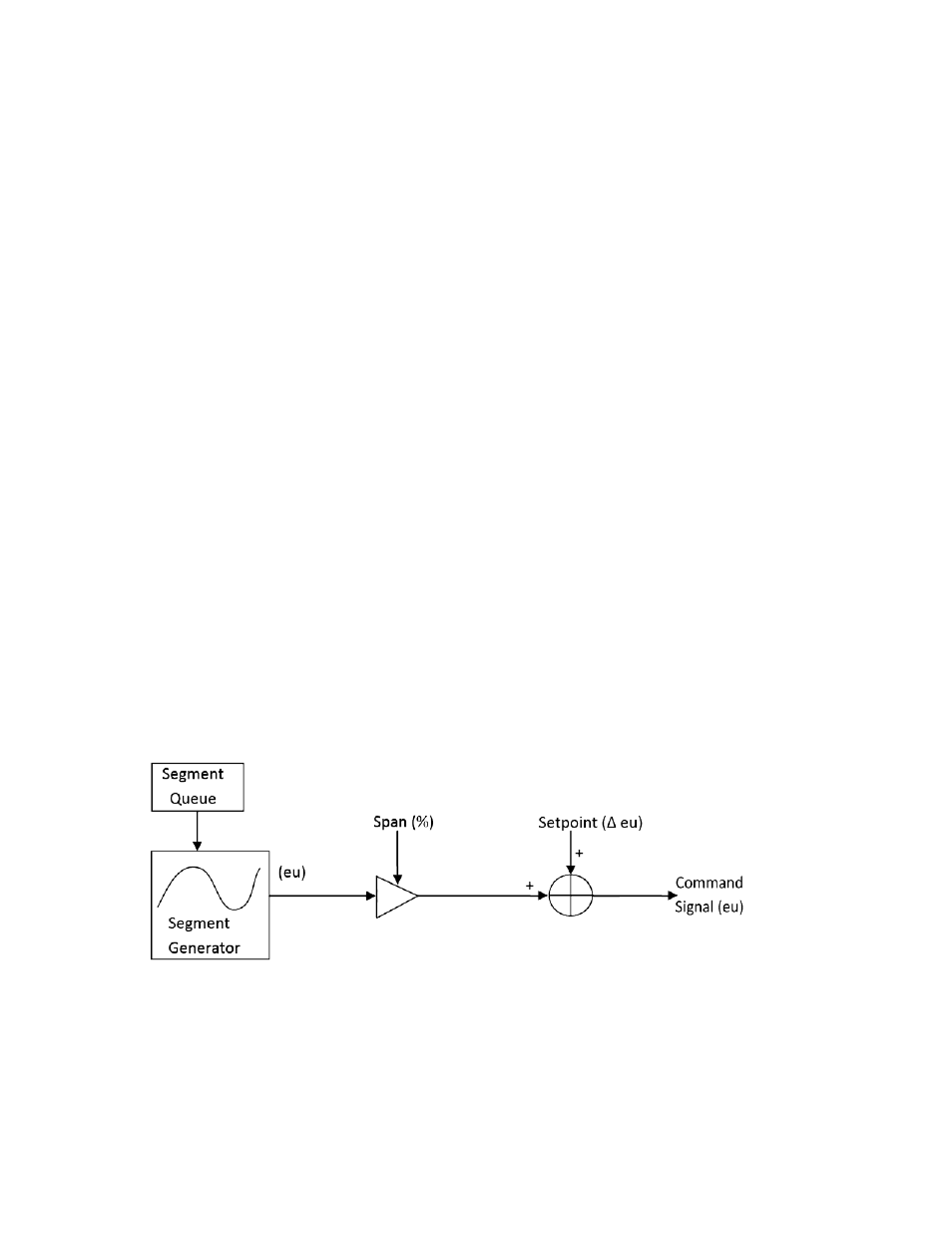

Segment Generator Diagram

The following diagram illustrates the relationship between the segment generator (internal to the controller)

and the Span and Setpoint controls in the Station Manager application for the FlexTest controller. The

Maintain Command feature applies the inverse of the span and setpoint values to the output of the

segment generator.

Segment Generator Diagram

MTS TestSuite | 425

Test Activities