Position lock tolerance – Rockwell Automation 1784-PM16SE SoftLogix Motion Card Setup and Configuration Manual User Manual

Page 407

Publication 1784-UM003A-EN-P – June 2003

Motion Object Attributes 399

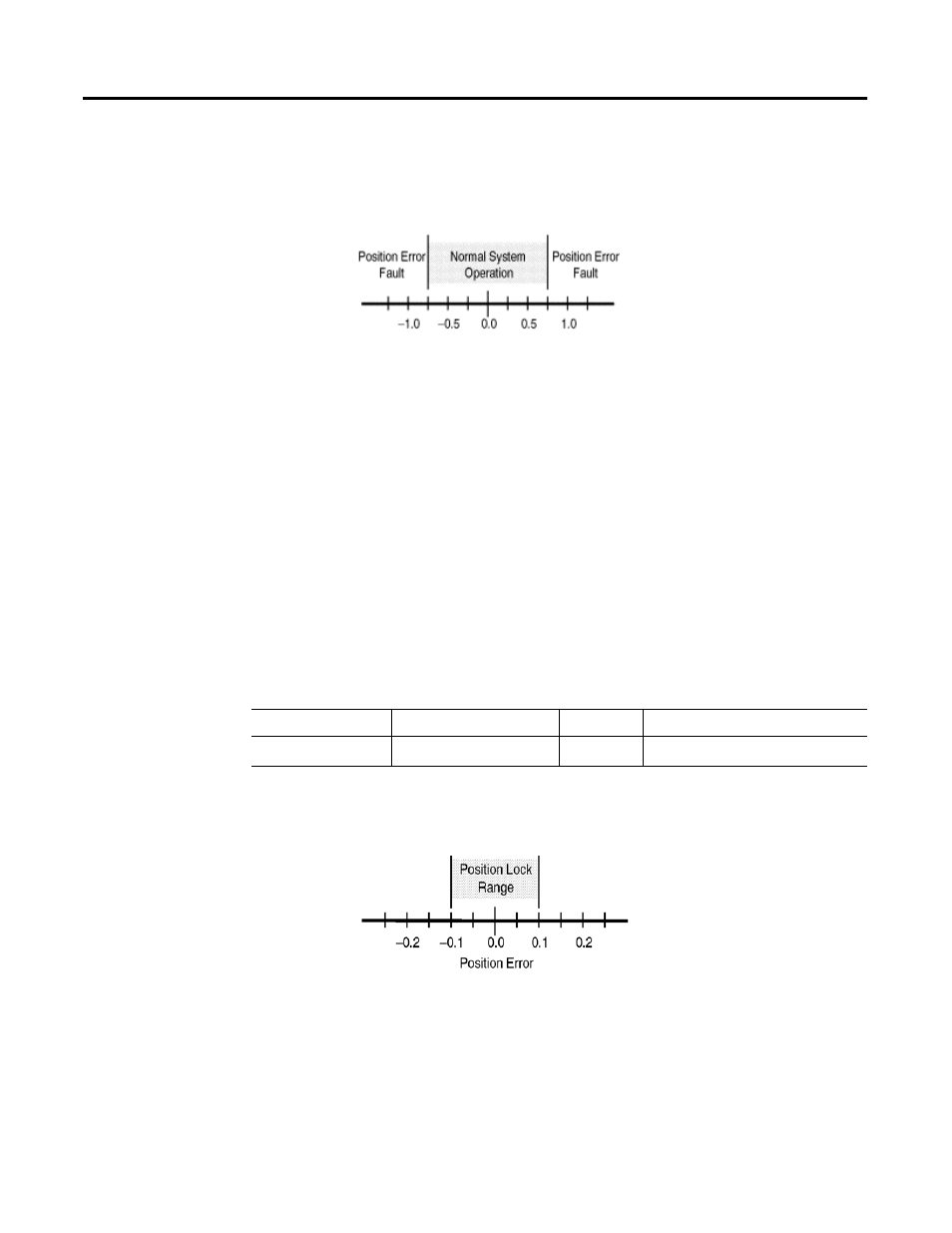

For example, specifying a position error tolerance of 0.75 Position Units

means that a Position Error Fault will be generated whenever the position

error of the axis is greater than 0.75 or less than -0.75 Position Units, as shown

below:

Figure 13.25 Position Error

The self tuning routine sets the position error tolerance to twice the following

error at maximum speed based on the measured response of the axis. In most

applications, this value provides reasonable protection in case of an axis fault

or stall condition without nuisance faults during normal operation. If you need

to change the calculated position error tolerance value, the recommended

setting is 150% to 200% of the position error while the axis is running at its

maximum speed.

Position Lock Tolerance

The Position Lock Tolerance attribute value specifies how much position error

the SERCOS module tolerates when giving a true Position Locked Status

indication. When used in conjunction with the Position Locked Status bit, it is

a useful parameter to control positioning accuracy. The Position Lock

Tolerance value should be set, in Position Units, to the desired positioning

accuracy of the axis.

The position lock tolerance value is interpreted as a ± quantity. For example, if

your position units are Inches, specifying a position lock tolerance of 0.01

provides a minimum positioning accuracy of ±0.01 inches as shown below.

Figure 13.26 Position Lock Range

GSV/SSV Access

Attribute Name

Data Type

Values

SSV/GSV

Position Lock Tolerance

REAL

Position Units