Product description – Lenze I/O system 1000 System Manual User Manual

Page 82

Product description

I/O compound modules − digital I/O

2 digital inputs with time stamp function − EPM−S207

l

82

EDSIO1000 EN 7.0

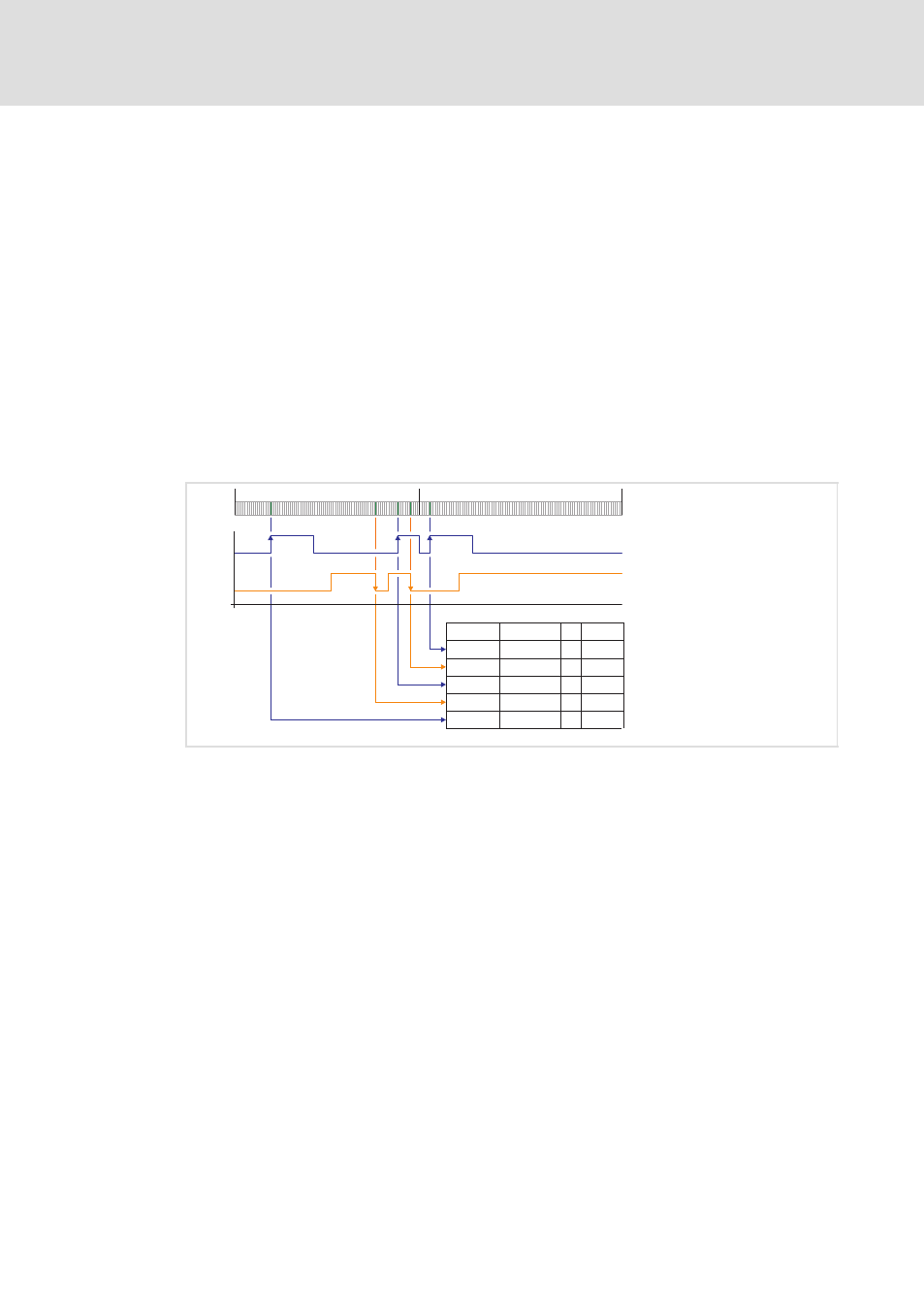

Functional principle taking the example of the system bus CAN

Long cycle times or fieldbus cycle times which fluctuate depending on bus load inevitably

result in unacceptable inaccuracy when precise switching times are needed. The time

stamp function can be used to calculate switching times for outputs accurate to 1

ms.

An I/O compound module with time stamp function is fitted with an internal ticker. The

tickers within a station are all synchronised via the backplane bus to ensure the same time

base.

ƒ

The ticker has a resolution of 1

ms. After power−on, it counts from 0 ... 65535 ms and

then goes back to 0.

ƒ

If using I/O compound modules with the time stamp function, when the signal

undergoes a edge change, the ticker value is saved to the process image along with

the channel status.

ƒ

Up to 15 DI switching orders (sub−index entries) can be transmitted with the time

stamp function.

65535 µs

0 µs

0 µs

65535 µs

0

00000001

00000001

00000011

00000000

00000001

1

4

0

1

2

3

2

4560

61210

56200

49150

16000

Sub-Index

+0

+16

+12

+8

+4

Ticker

DI1

DI2

SLIO080

Fig. 3−20

Saving the time stamp entries

DI1

Digital input 1

The time stamp entry for the edge evaluation is generated with a rising edge.

DI2

Digital input 2

The time stamp entry for the edge evaluation is generated with a falling edge.

0

Channel status

1

Running number (RN)

Counts from 0

127 and then starts with 0 again. The consecutive number reflects the

time sequence of the edges.

2

Ticker value