Monitoring time – Festo Кабели и принадлежности User Manual

Page 319

7. Description of the commands

7−53

Festo P.BE−SPC200−EN en 0901d

G60

Exact stop without damping time

ć pneumatic axis; ć permitted in operating mode: Start/Stop, Record Select

Nn G60 X [Y, Z, U]

Effect

Switches the specified axis to exact stop without damping time (positioning quality

class 3, see also under G61).

Output MC_A/MC_B or RC_A/RC_B always supplies a 1−signal when the specified

axis is within the range of the positioning tolerance for the complete duration of

the monitoring time (see also Fig. 7/13). If the axis leaves the tolerance range

before the monitoring time expires, the monitoring time will be reset.

Example

N000 G60 X

N001 G00 X100

;Activate exact stop without damping time

;Move to position X100

(example: Positioning tolerance = 0.2 mm): When moving to position 100 mm,

output MC_A/MC_B or RC_A/RC_B always supplies a 1−signal when the X−axis is

within the range of the positioning tolerance (between 99.8...100.2 mm).

Remark

This command has a saving effect. It remains effective until a switch is made to

Fast Stop with command G62 or to any other positioning quality class with

command G61.

With nominal value modes 0 and 1, the set positioning quality class has no effect

(see NC command M13).

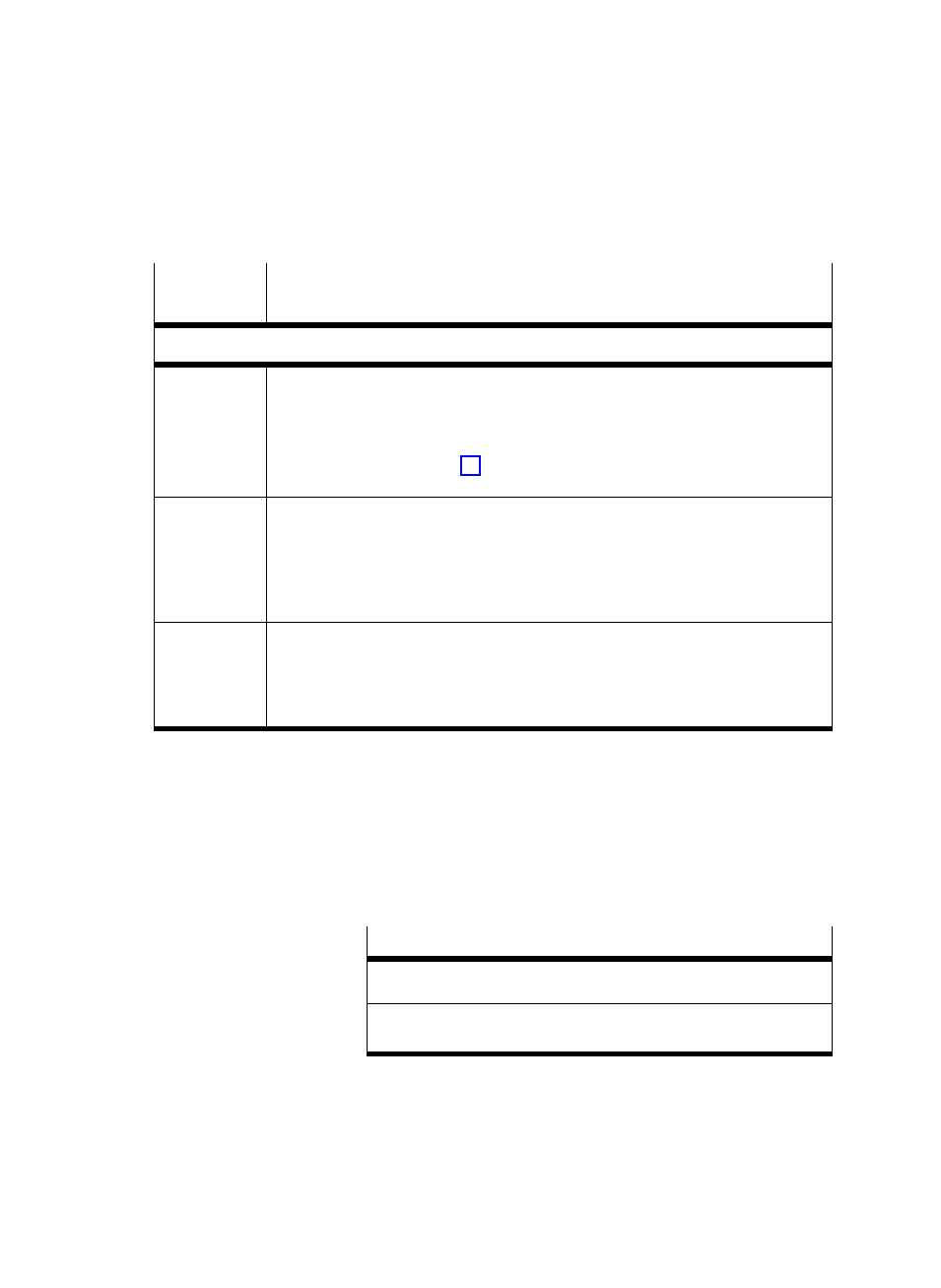

Monitoring time

With the rotary module and with linear drives with a length of

< 300 mm the monitoring time is 20 ms. For linear drives with

a length of > 300 mm the monitoring time can be calculated

as follows:

Formula for linear drives over 300 mm in length

T

monitoring

+

ǒ

L

drive

) 100

Ǔ

B 20

T

monitoring

= monitoring time

in [ms]

L

drive

= stroke length of linear drive in [mm]

Example linear drive (stroke length 500 mm):

Monitoring time in [ms] = (500 + 100) / 20 = 30