Festo Кабели и принадлежности User Manual

Page 266

6. Operating the SPC200 with the control panel

6−54

Festo P.BE−SPC200−EN en 0901d

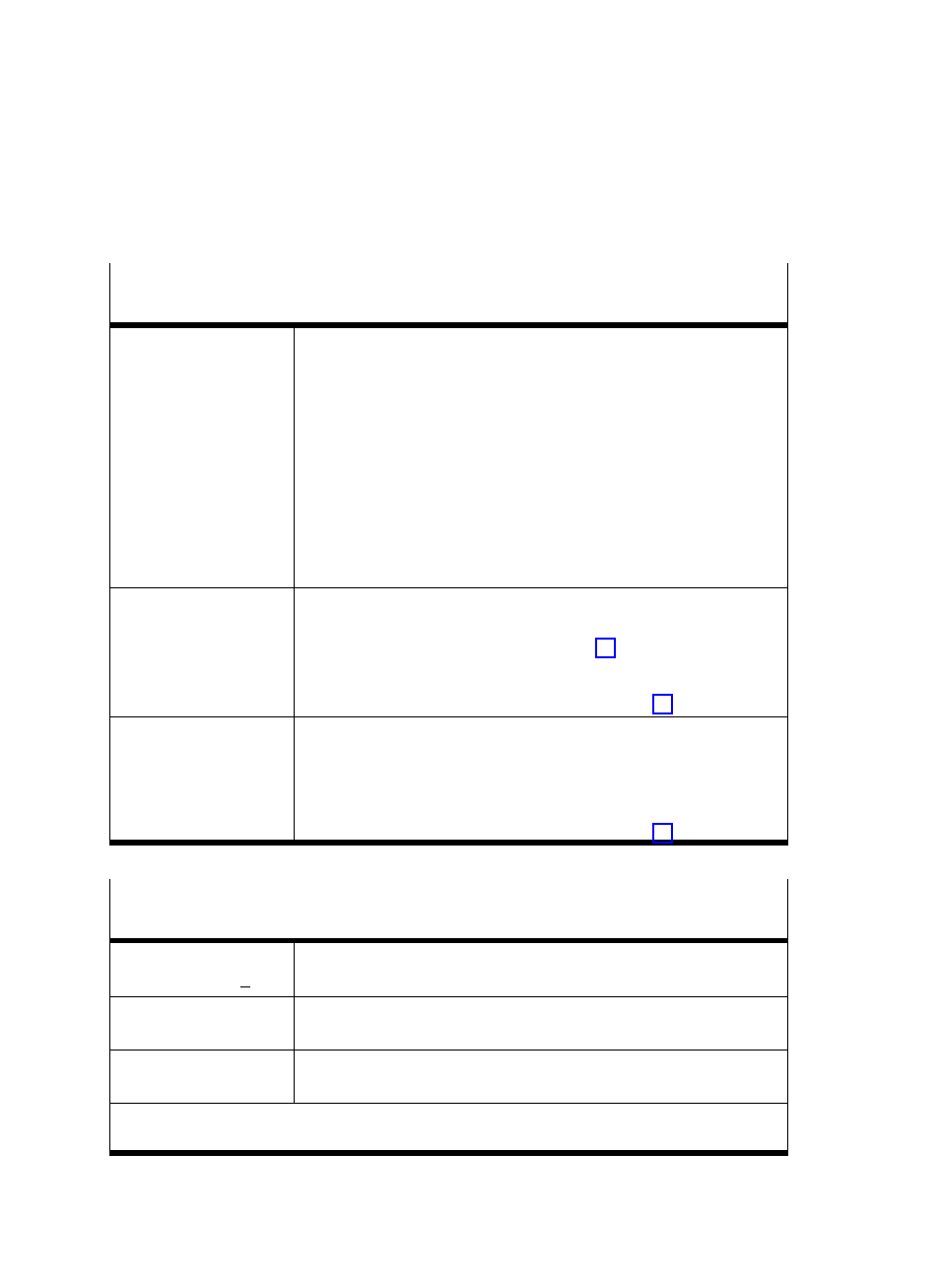

Menu TEST/DIAG. (test and diagnosis)

Sub−menu AXIS: Pneumatic axis

JOG AXIS

X: CONT

Position axis

CONT

; position continuously

STEP

; position in steps twice the set positioning tolerance

Proceed as follows:

1. Select the desired axis (X or Y).

2. Positioning mode (CONT, STEP).

3. Press the Enter button to confirm the selection.

4. Select positioning direction (+ or −).

5. With positioning mode STEP:

ć Press the Enter button in order to move one step.

With positioning mode CONT:

ć Hold the Enter button pressed down for as long as positioning is

carried out.

MOVEMENT TEST

X:05.00 V

Movement test

00.00 ... 10.00 V

Observe the note on compatibility in chapter 4.4.2.

With this command you can check whether the proportional directional

control valve is connected correctly with its axis.

Instructions on this procedure can be found in chapter 4.4.2.

IDENTIFICATION

X:STATIC

System identification

STATIC

; static identification

DYNAMIC1

; dynamic identification with workpiece

DYNAMIC2

; dynamic identification without workpiece

The max. workpiece mass set with the application data is valid.

Instructions on this procedure can be found in chapter 4.4.2.

Menu TEST/DIAG. (test and diagnosis)

Sub−menu AXIS: Electric axis

JOG AXIS

X: +0000.00 +

Position axis

1)

EXIT FROM LIMIT

X:+0000.00 ?

Emergency travel

1)

REFER. TRAVEL

X:+0000.00 ?

Reference travel

1)

1)

Explanations as well as instructions on carrying out these activities can be found in the manual

for the stepping motor indexer module type P.BE−SPC200−SMX−1−...Ă.