Jam protection – Rockwell Automation 592- E300 Overload Relay User Manual User Manual

Page 98

98

Rockwell Automation Publication 193-UM015B-EN-P - June 2014

Chapter 5 Protective Trip and Warning Functions

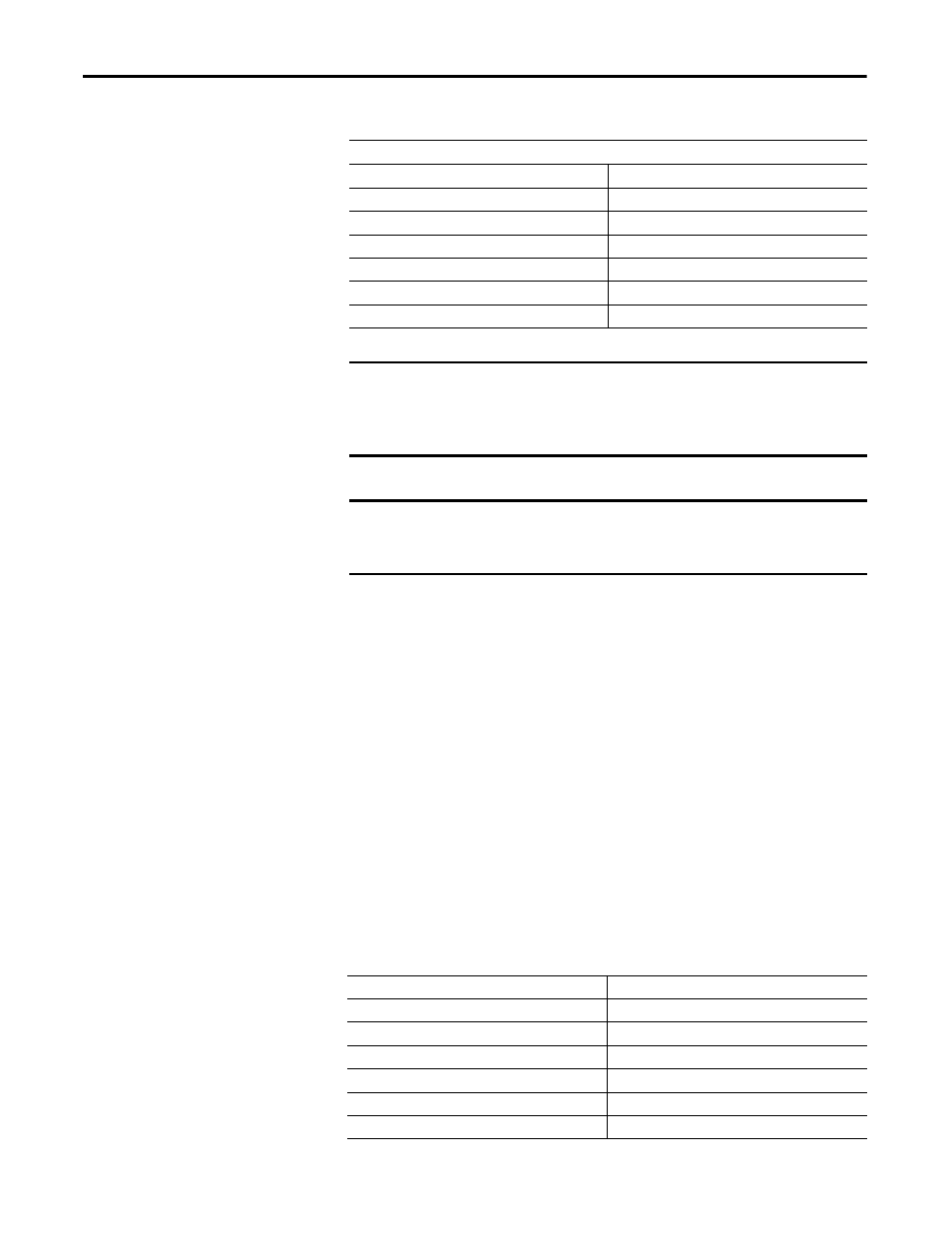

Table 80 - Stall Trip Level (Parameter 250)

Jam Protection

A motor goes into a jam condition when a running motor begins to consume

current greater than50% of the motor’s nameplate rating. An example of this

condition could be an overloaded conveyor or jammed gear. These conditions

can result in the overheating of the motor and equipment damage. The E300

Electronic Overload Relay can monitor for this condition with its Jam Trip and

Warning function to detect for a rapid jam fault to minimize damage and loss of

production.

Jam Inhibit Time

Jam Inhibit Time (Parameter 251) allows the installer to inhibit a jam trip and

warning from occurring during the motor starting sequence. It is adjustable from

0…250 s.

Table 81 ‐ Jam Trip Inhibit Time (Parameter 251)

Stall Trip Level (Parameter 250)

Default Value

600

Minimum Value

100

Maximum Value

600

Parameter Type

UINT

Size (Bytes)

2

Scaling Factor

1

Units

%FLA

IMPORTANT

Stall Protection is only enabled during the motor starting sequence. If the

maximum phase of load current falls below the programmed Stall Trip Level

before the Stall Enabled Time elapses, the E300 Electronic Overload Relay

disables Stall Protection until the next motor starting sequence.

IMPORTANT

The E300 Electronic Overload Relay considers a motor to have begun its

starting sequence if the maximum phase of motor current transitions from 0A

to approximately 30% of the device’s minimum FLA Setting.

Default Value

10

Minimum Value

0

Maximum Value

250

Parameter Type

USINT

Size (Bytes)

1

Scaling Factor

1

Units

Sec