Trip/warn led troubleshooting procedures – Rockwell Automation 592- E300 Overload Relay User Manual User Manual

Page 320

320

Rockwell Automation Publication 193-UM015B-EN-P - June 2014

Chapter 10 Troubleshooting

•

Setting Overload Reset Mode (Parameter 173) to “Automatic” to allow the

unit to automatically reset after an overload trip

•

Setting Trip Reset (Parameter 163) to a value of 1, “Trip Reset”

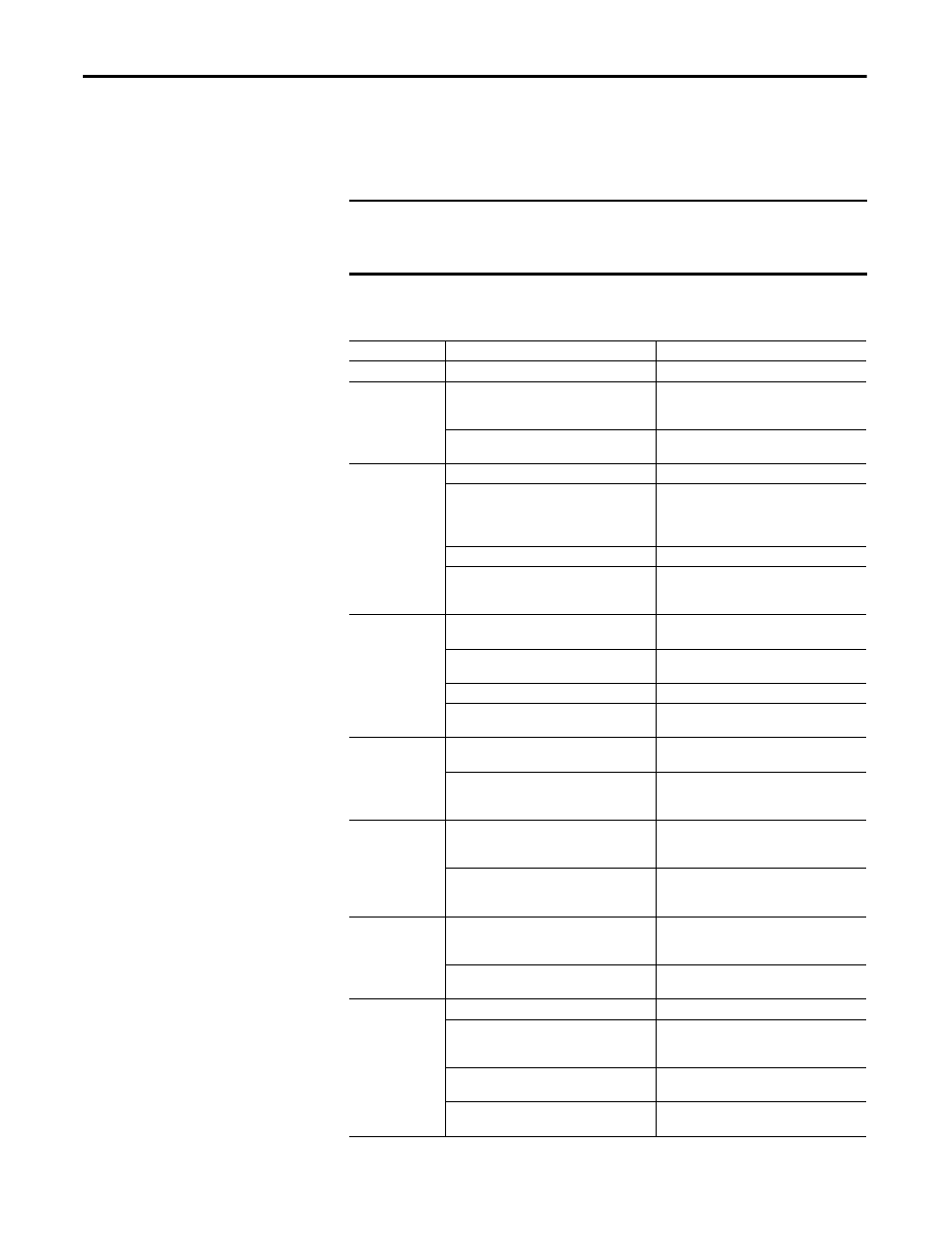

Trip/Warn LED

Troubleshooting Procedures

IMPORTANT

An overload trip cannot be reset until the value of Percent Thermal Capacity

Utilized (Parameter 1) is below the value set in Overload Reset Level

(Parameter 174).

Trip Description

Possible Cause

Corrective Action

Test Trip

1. Operation of the Test/Reset

1. Operate the Test/Reset button to clear

Overload

1. Motor overloaded

1. Check and correct source of overload (load,

mechanical transmission components, motor

bearings).

2. Improper parameter settings

2. Set parameter values to match the motor and

application requirements.

Phase Loss

1. Missing supply phase

1. Check for open line (i.e. blown fuse).

2. Poor electrical connection

2. Check all power terminations from the branch

circuit-protecting device down to the motor for

proper tightness. Ensure that the overload

connection to the contactor is secure.

3. Contactor operation

3. Inspect contactor for proper operation.

4. Improper parameter setting

4. Single-phase applications require that

Single/Three Phase (Parameter 176) is set to

“single phase”.

Ground Fault

1. Power conductor or motor winding is

shorting to ground

1. Check power conductors and motor windings

for low resistance to ground.

2. Motor winding insulation is decayed

2. Check motor winding insulation for low

resistance to ground.

3. Foreign Object short

3. Check for foreign objects.

4. External ground fault sensor (core balance

current transformer) has improper connection

4. Check cable connections.

Stall

1. Motor has not reached full speed by the end

of the Stall Enabld Time (Parameter 249)

1. Check for source of stall (i.e. excessive load, or

mechanical transmission component failure).

2. Improper parameter settings

2. Stall Enabled Time (Parameter 249) is set too

low for the application. Check to ensure that

FLA Setting (Parameter 171) is set correctly.

Jam

1. Motor current has exceeded the programmed

jam level

1. Check for the source of the jam (i.e., excessive

load or mechanical transmission component

failure).

2. Improper parameter settings

2. Jam Trip Level (Parameter 253) is set too low

for the application. Check to ensure that FLA

Setting (Parameter 171) is set correctly.

PTC

1. Motor stator windings overheated

1. Check for source of motor overtemperature

(i.e. overload, obstructed cooling, high ambient

temperature, excessive starts/hour).

2. Thermistor leads short-circuited or broken

2. Inspect thermistor leads for short-circuit or

open

Current Imbalance

1. Imbalance in incoming power

1. Check power system (i.e. blown fuse).

2. Motor winding imbalance

2. Repair motor, or if acceptable, raise value of

Current Imbalance Trip Level (Parameter 261),

CI Trip Level

3. Motor idling

3. Raise value of Current Imbalance Trip Level

(Parameter 261) to an acceptable level.

4. Contactor or circuit breaker operation

4. Inspect contactor and circuit breaker for

proper operation.