Rockwell Automation 592- E300 Overload Relay User Manual User Manual

Page 82

82

Rockwell Automation Publication 193-UM015B-EN-P - June 2014

Chapter 5 Protective Trip and Warning Functions

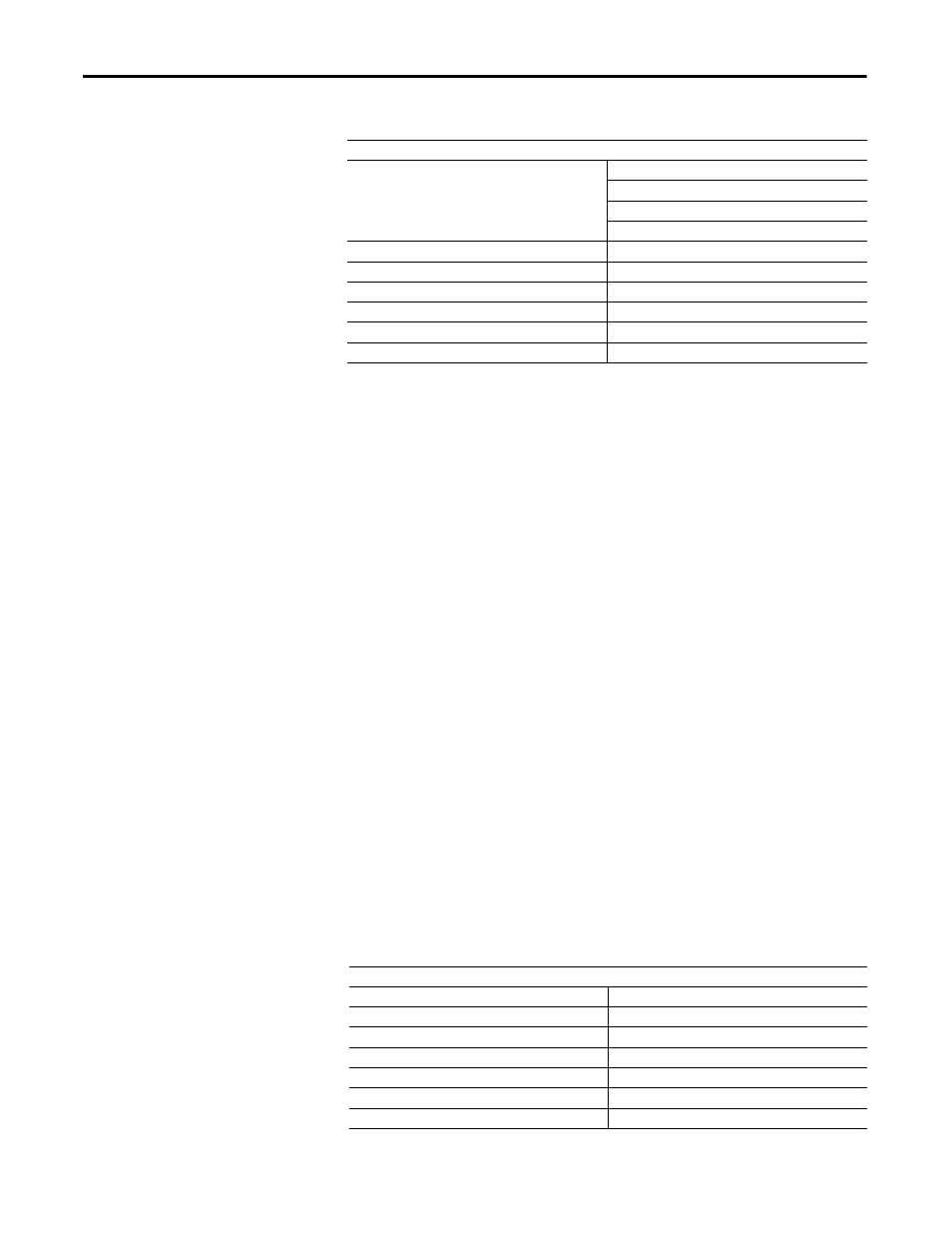

Table 59 - FLA2 (Parameter 177)

USA & Canada Guidelines

•

Motor Service Factor ≥ 1.15: For motors with a service factor rating of

1.15 or greater, program the FLA setting to the printed nameplate’s full

load current rating.

•

Motor Service Factor < 1.15: For motors with a service factor rating less

than 1.15, program the FLA setting to 90% of the printed nameplate’s full

load current rating.

•

Wye-Delta (Y-Δ) Applications: Follow the application’s service factor

instructions, except divide the printed nameplate’s full-load current rating

by 1.73.

Outside USA & Canada Guidelines

•

Maximum Continuous Rated (MCR) Motors: Program the FLA setting

to the printed nameplate’s full-load current rating.

•

Star-Delta (Y-Δ) Applications: Follow the MCR instructions, except

divide the printed nameplate’s full-load current rating by 1.73.

Trip Class

Trip Class is the second of two parameters that affect the E300 Electronic

Overload Relay’s thermal capacity utilization algorithm. Trip class is defined as

the maximum time (in seconds) for an overload trip to occur when the motor’s

operating current is six times its rated current. The E300 Electronic Overload

Relay offers an adjustable trip class range of 5…30. The user enters the

applications trip class into Trip Class (Parameter 172).

Table 60 - Trip Class (Parameter 172)

FLA2 (Parameter 177)

Default Value

0.50 (0.5…30 A Sensing Modules)

6.00 (6…60 A Sensing Modules)

10.00 (10…100 A Sensing Modules)

20.00 (20…200 A Sensing Modules)

Minimum Value

0.50

Maximum Value

65535.00

Parameter Type

UDINT

Size (Bytes)

4

Scaling Factor

100

Units

Amps

Trip Class (Parameter 172)

Default Value

10

Minimum Value

5

Maximum Value

30

Parameter Type

USINT

Size (Bytes)

1

Scaling Factor

1

Units