Underload protection – Rockwell Automation 592- E300 Overload Relay User Manual User Manual

Page 101

Rockwell Automation Publication 193-UM015B-EN-P - June 2014

101

Protective Trip and Warning Functions Chapter 5

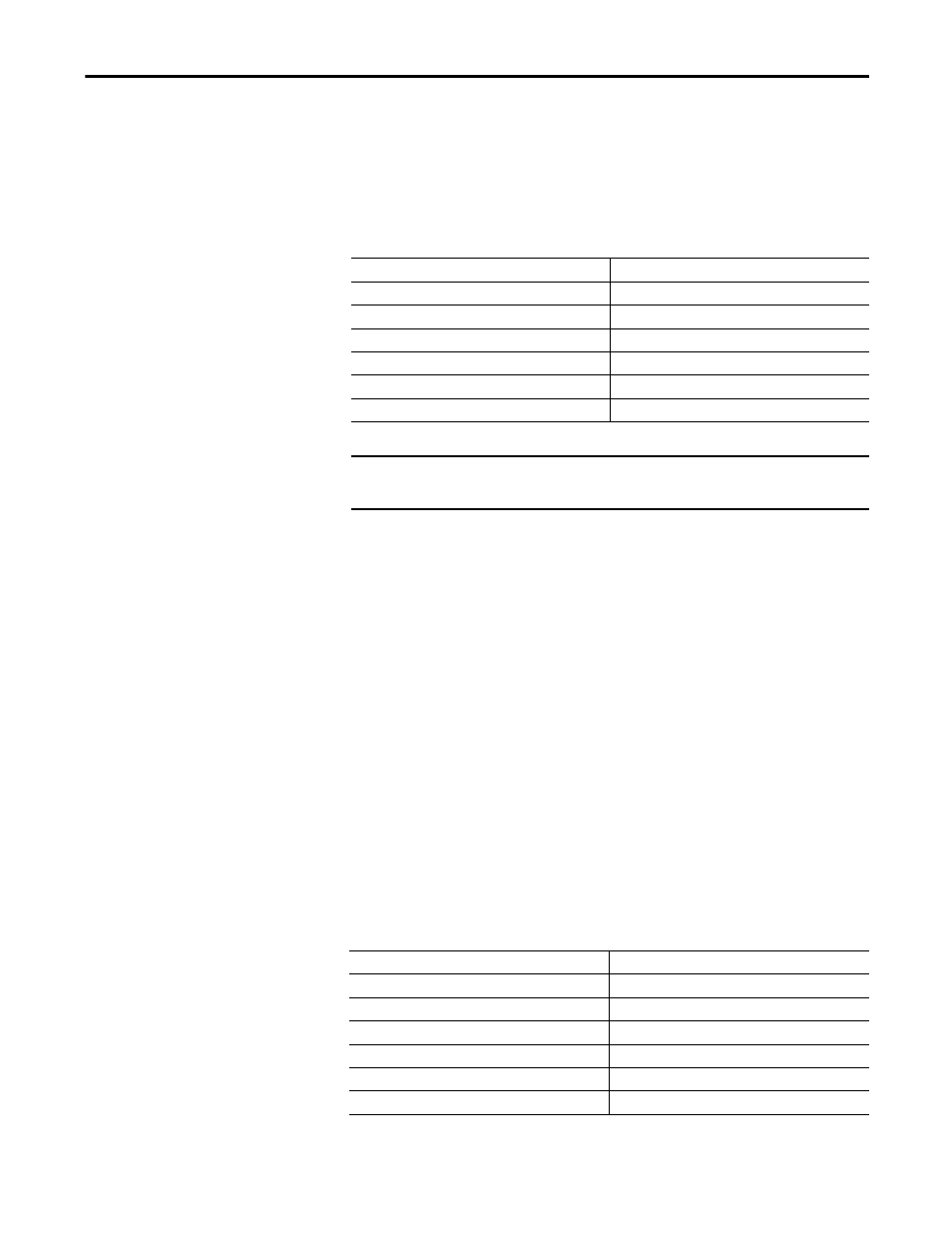

Jam Warn Level

Jam Warn Level (Parameter 254) allows the user to define the current at which

the E300 Electronic Overload Relay will indicate a warning. It is user-adjustable

from 50…600% for the FLA Setting (Parameter 171).

Table 84 - Jam Warning Level (Parameter 254)

Underload Protection

Motor current less than a specific level may indicate a mechanical malfunction in

the installation, such as a torn conveyor belt, damaged fan blade, broken shaft, or

worn tool. Such conditions may not harm the motor, but they can lead to loss of

production. Rapid underload fault detection helps to minimize damage and loss

of production.

The E300 Electronic Overload Relay can monitor for this condition with its

Underload Trip and Warning function to detect for a rapid underload fault to

minimize damage and loss of production.

Underload Inhibit Time

Underload Inhibit Time (Parameter 255) allows the installer to inhibit an

underload trip and warning from occurring during the motor starting sequence. It

is adjustable from 0…250 s.

Table 85 - Underload Inhibit Time (Parameter 255)

Default Value

150

Minimum Value

50

Maximum Value

600

Parameter Type

UINT

Size (Bytes)

2

Scaling Factor

1

Units

%FLA

IMPORTANT

The Jam Warning function does not include a time delay feature. Once the Jam

Inhibit Time has expired, the Jam Warning indication is instantaneous.

Default Value

10

Minimum Value

0

Maximum Value

250

Parameter Type

USINT

Size (Bytes)

1

Scaling Factor

1

Units

Sec