Typical motor connections – Rockwell Automation 592- E300 Overload Relay User Manual User Manual

Page 43

Rockwell Automation Publication 193-UM015B-EN-P - June 2014

43

Installation and Wiring Chapter 2

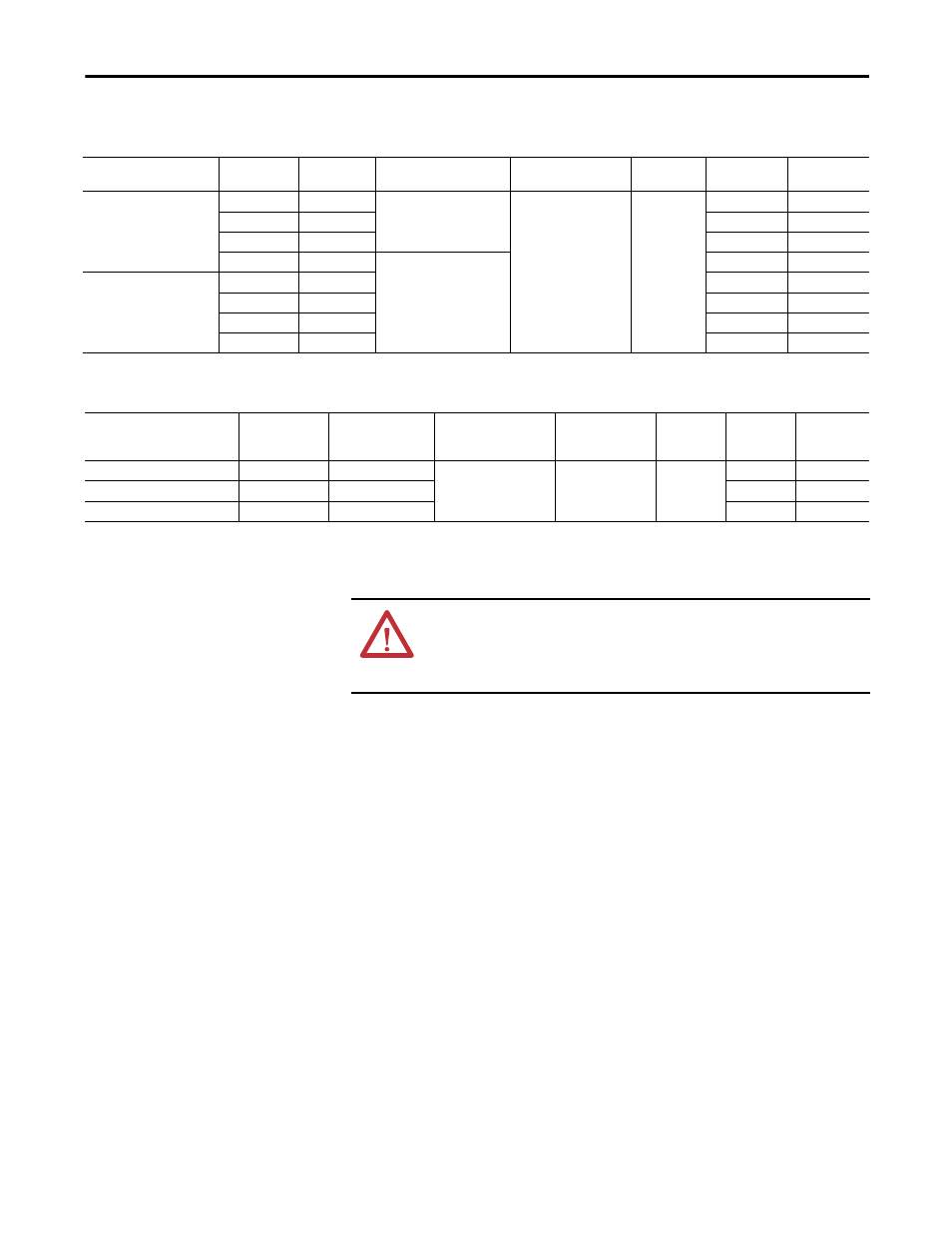

Table 11 - Type 1 and Type II fuse coordination with Bul. 100-C and 100-D contactors per

EN60947-4-1

Table 12 - Type 1 and Type II fuse coordination with Bul. 100-C and 100-D contactors

per EN60947-4-1

Typical Motor Connections

Three-Phase Direct On-Line (DOL) & Single-Phase Full Voltage

The following wiring diagram illustrates the E300 Electronic Overload Relay

typical motor connections in a three-phase DOL and Single-Phase Full Voltage

applications.

Overload Relay using

Sensing Module Cat. No.

Contactor Cat.

No.

Max. Starter

FLC[A]

Prospective Short-Circuit

Current, I

r

[A]

Conditional Short-

Circuit Current, I

q

[A]

Max. Voltage

[V]

Type I Class J or

CC Fuse [A]

Type II Class J

or CC Fuse [A]

193-ESM-___-30A-C23

100-C09

9

1000

100,000

600

20

15

100-C12

12

20

20

100-C16

16

30

30

100-C23

23

3000

40

40

193-ESM-___-30A-C55,

193-ESM-___-60A-C55

100-C30

30

50

50

100-C37

37

50

50

100-C43

43

70

70

100-C55

55

80

80

Overload Relay using Sensing

Module Cat. No.

Contactor Size

Max. Starter FLC[A]

Prospective Short-

Circuit Current, I

r

[A]

Conditional Short-

Circuit Current, I

q

[A]

Max. Voltage

[V]

Type I Class J

Fuse [A]

Type II Class J

Fuse [A]

592-ESM-___-30A-S2

0

18

3000

100,000

600

30

30

592-ESM-___-30A-S2

1

27

30

30

592-ESM-___-60A-S2

2

45

60

60

ATTENTION: When working on energized circuits, DO NOT rely on voltage and

current information provided by the E300 Electronic Overload Relay for personal

safety. Always use a portable voltage or current measurement device to

measure the signal locally.