S on – Rockwell Automation Energy Management Accelerator Toolkit Quick Start User Manual

Page 84

84

Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014

Chapter 3 Energy Data Collector Configuration

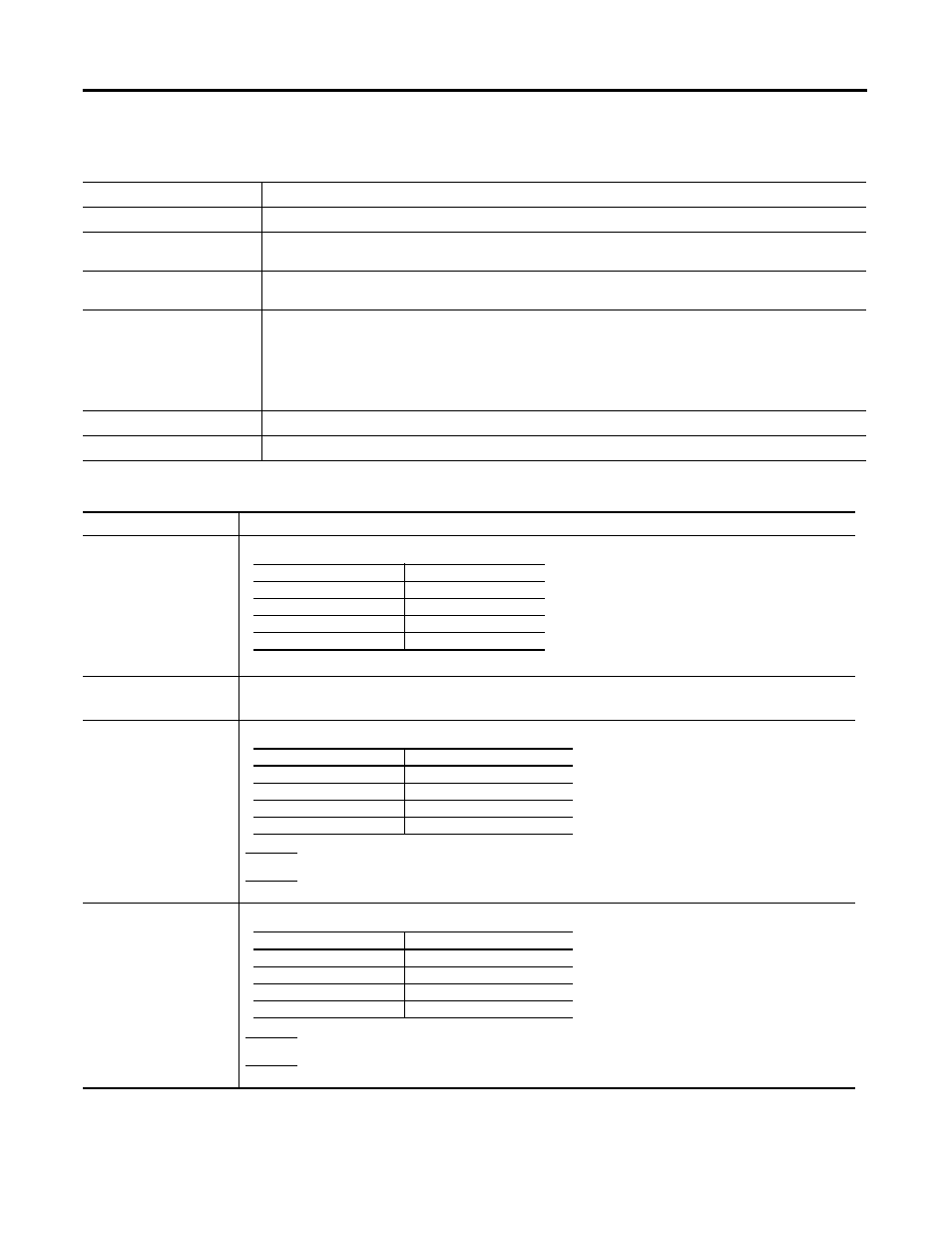

Energy Add-On Instruction Factors for Electric Inputs

Energy Factor Tag

Description

Set_Meter_Pulse_Factor

The kWh value used to scale the input pulses. The value 1.5 represents 1.5 kWh per pulse.

Set_Demand_Interval

The value, in minutes, used to calculate the End of Demand Interval (EOI). This value is used only if the Val_End_of

Demand_Type is 2.

Set_Demand_Delay

The time value used to reset the end of interval after the Set_Demand_Interval value has been exceeded without a

utility contact or master end of demand contact closure. The value must be in the range of 0…90 seconds.

Set_End_of_Demand_Interval_

Type

The value that defines how the End of Demand Interval (EOI) is triggered.

1 = A local digital input connected to an electric utility meter EOI contact (Inp_End_of_Demand_Utility_Contact).

2 = An internal PLC timer (Demand_Interval _PLC Timer) that is typically used when an electric utility meter EOI

contact is not available.

3 = A master command input (CMD_Master_End_Of_Demand_Interval) typically from a central controller that is used

to synchronize multiple electric meter EOIs.

Set_High_Demand

When the demand (kW) value exceeds the Set_High_Demand, the High Demand Fault is set.

Set_Critical_Demand

When the demand (kW) value exceeds the Set_Critical_Demand, the High Critical Fault is set.

Energy Add-On Instruction Factors for Gas, Propane, Fuel Oil, Steam, Air and Water Inputs

Energy Factor Tag

Definitions

Set_Meter_Pulse_Factor

(1)

(1) The Set_Meter_Pulse_Factor applies only to Energy_xxx_Digital Add-On Instructions. Analog inputs must be scaled to represent flow by using the

engineering units in the table.

The consumption value of each input pulse.

For example, a value of 1.5 for the Energy_Gas_Digital Add-On Instruction, represents 1.5 therms per pulse.

Set_Calc_Interval

The time interval, in minutes, used to calculate the average energy flow.

For example, an interval value of 5 will calculate the average energy flow every 5 minutes.

Set_High_Flow

When the flow rate value exceeds the Set_High_Flow value, the High Flow Fault is set.

Example 1: A value of 500 will set the High Flow Fault in the Energy_Gas_Digital Add-On Instruction when the gas flow

rate exceeds 500 therms/hr.

Example 2: A value of 500 will set the High Flow Fault in the Energy_Air_Analog Add-On Instruction when the air flow

rate exceeds 500 cfm.

Set_Critical_Flow

When the flow rate value exceeds the Set_Critical_Flow value, the Critical Flow Fault is set.

Example 1: A value of 750 will set the Critical Flow Fault in the Energy_Gas_Digital Add-On Instruction when the gas

flow rate exceeds 750 therms/hr.

Example 2: A value of 750 will set the Critical Flow Fault in the Energy_Air_Analog Add-On Instruction when the air flow

rate exceeds 750 cfm.

Energy Add-On Instruction

Default Consumption Unit

Air

cf (cubic feet)

Fuel Oil, Propane, Water

gallons

Gas

therms

Steam

lbs (pounds)

Energy Add-On Instruction

Default Flow Rate Unit

Air

cfm (cubic feet per min)

Fuel Oil, Propane, Water

gpm (gallons per min)

Gas

therms/hr

Steam

lbs/hr

Energy Add-On Instruction

Default Flow Rate Unit

Air

cfm (cubic feet per min)

Fuel Oil, Propane, Water

gpm (gallons per min)

Gas

therms/hr

Steam

lbs/hr