Demand control configuration, Priority levels, Interlocks – Rockwell Automation Energy Management Accelerator Toolkit Quick Start User Manual

Page 377

Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014

377

Demand Control Chapter 12

Demand Control Configuration

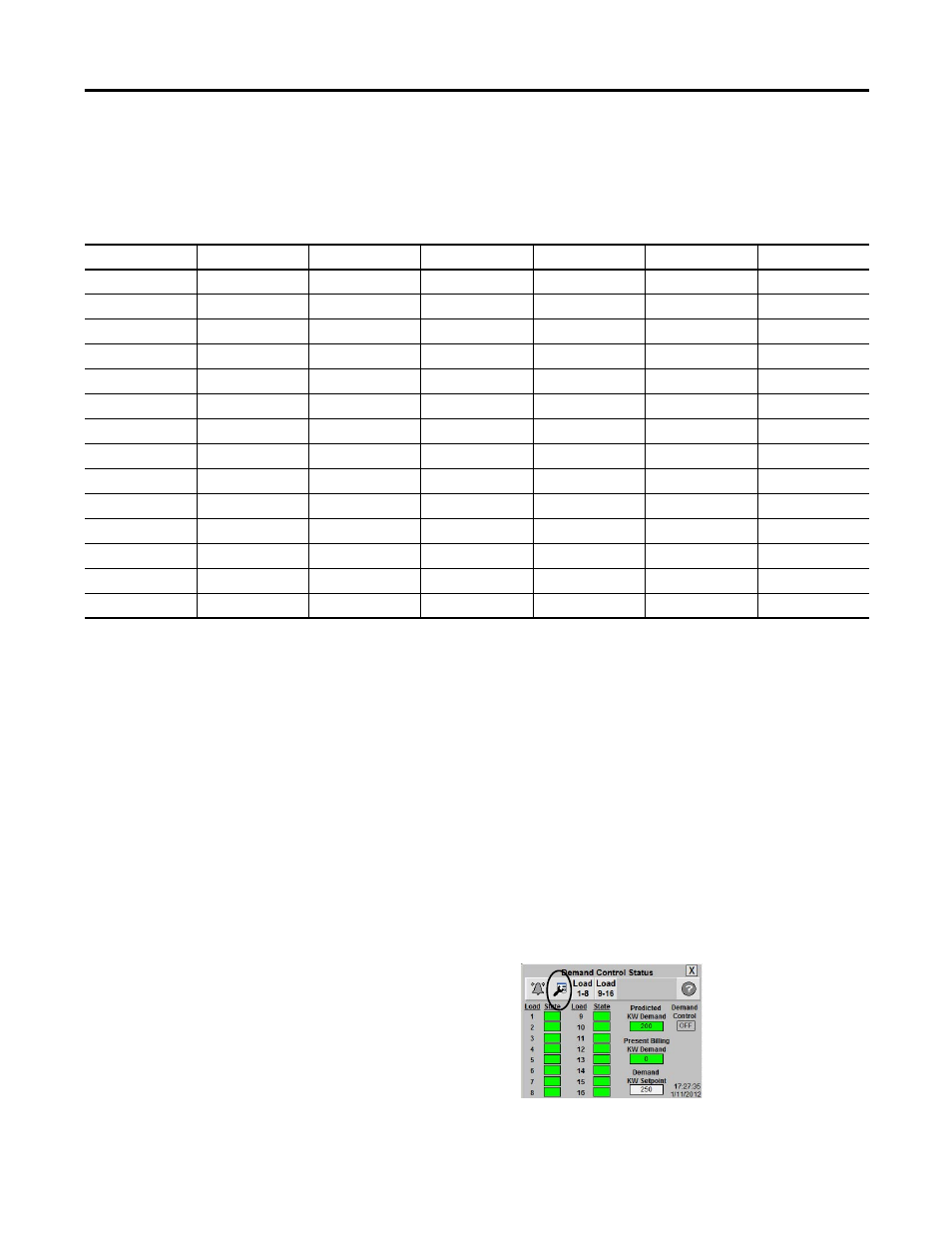

Prior to configuring the loads in the controller, you must assign priority levels and interlock times to the loads in your

application. The configuration for the Efficient Industries Plant 1 Example is shown below:

Priority Levels

• There are up to 16 priority levels available.

• Loads with the largest priority number are shed first (priority level 1 is shed last).

• More than one load may be assigned to a given priority level. If loads share the same priority level, they will be shed

based on the time since the load was last shed. (In other words, when a shed is required, the running load with the

largest priority level number and the longest minutes since shed will be the next load to shed.)

Interlocks

• On Delay interlock is the minimum time the load must be off, in seconds, before it can be restarted.

• Off Delay interlock is the minimum time the load must be on, in seconds, before it can be shed.

• Max Off Time interlock is the maximum amount of time, in seconds, that the load is allowed to be shed per hour.

Configure the individual loads and the demand control schedule.

1.

Click the configuration button on the toolbar.

Load

Description

Rated KW

Priority

On Delay (s)

Off Delay (s)

Max Off Time (s)

1

Air Compressor 1

21

1

60

60

900

2

Air Compressor 2

21

1

60

60

900

3

AHU 1 Production

15

4

120

120

1800

4

AHU 2 Production

15

4

120

120

1800

5

AHU 3 Shipping

12

5

120

120

1800

6

AHU 4 Office

10

7

120

120

1800

7

Exhaust Fan 1

2

2

30

30

2700

8

Exhaust Fan 2

2

2

30

30

2700

9

Exhaust Fan 3

2

10

30

30

2700

10

Exhaust Fan 4

2

10

30

30

2700

11

Lighting Production 6

3

15

15

1200

12

Lighting Production 6

6

15

15

1200

13

Lighting Shipping

6

8

15

15

3600

14

Lighting Office

6

9

15

15

3600