Delta DVP-ES2 User Manual

Page 366

D V P - E S 2 / E X 2 / S S 2 / S A2 / S X 2 / S E O p e r a t i o n M a n u a l - P r o g r a m m i n g

3-250

Step 2:

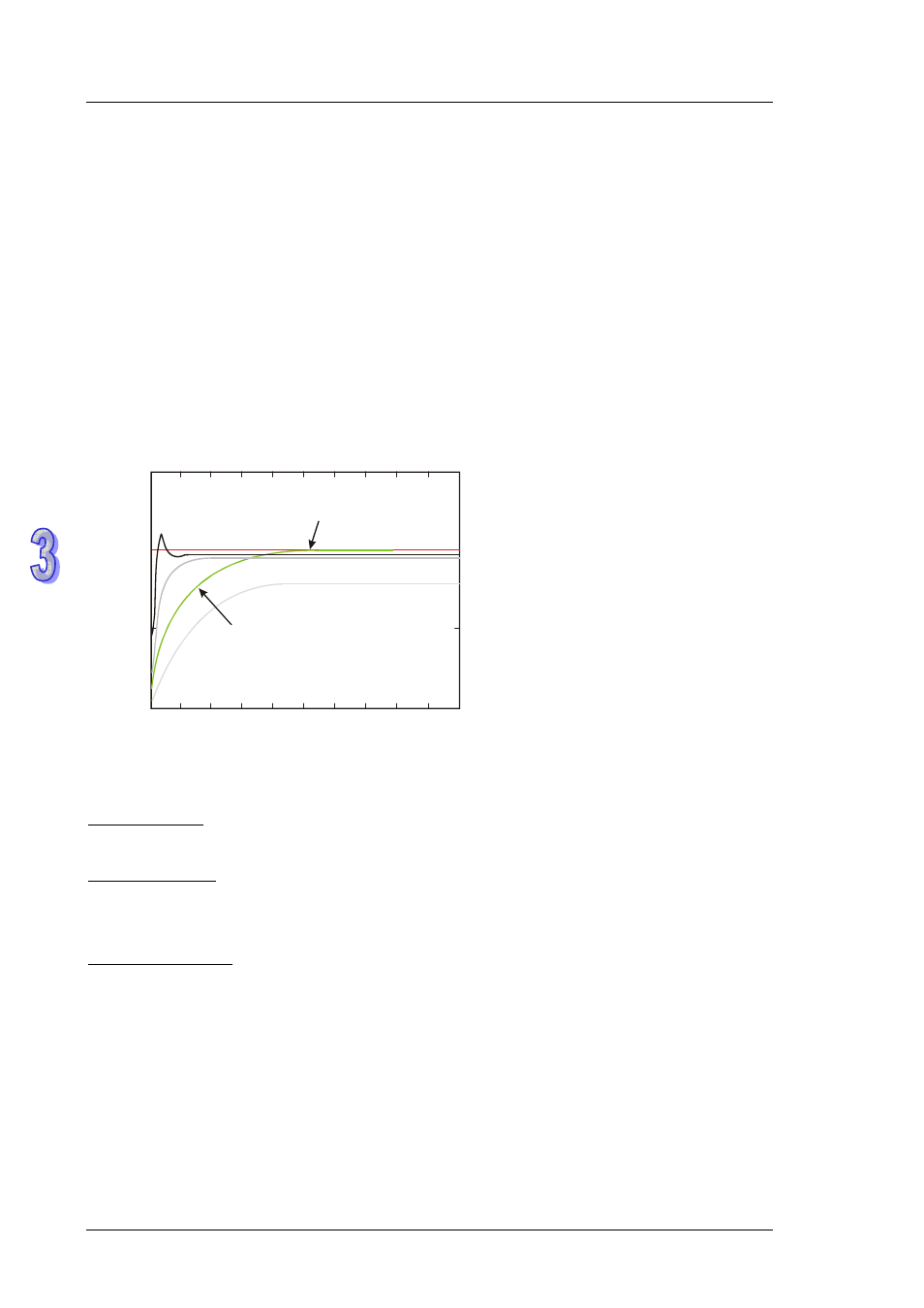

When K

P

is 40, response overshoot occurs, so we will not select it.

When K

P

is 20, PV response is close to SV and won’t overshoot, but transient MV will be to large

due to a fast start-up. We can put it aside and observe if there are better curves.

When K

P

is 10, PV response is close to SV and is smooth. We can consider using it.

When K

P

is 5, the response is too slow. So we won’t use it.

Step 3:

Select K

P

= 10 and increase K

I

gradually, e.g. 1, 2, 4, 8. K

I

should not be bigger than K

P

. Then,

increase K

D

as well, e.g. 0.01, 0.05, 0.1, 0.2. K

D

should not exceed 10% of K

P

. Finally we obtain the

figure of PV and SV below.

1.5

1

0.5

0

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

PV=SV

K =10,K =8,K =0.2

P

I

D

Time (sec)

Application 1:

PID instruction in pressure control system. (Use block diagram of example 1)

Control purpose:

Enabling the control system to reach the target pressure.

Control properties:

The system requires a gradual control. Therefore, the system will be overloaded or out of

control if the process progresses too fast.

Suggested solution:

Solution 1: Longer sampling time

Solution 2: Using delay instruction. See the figure below