1 creating a plc ladder program – Delta DVP-ES2 User Manual

Page 14

D V P - E S 2 / E X 2 / S S 2 / S A2 / S X 2 / S E O p e r a t i o n M a n u a l - P r o g r a m m i n g

1-6

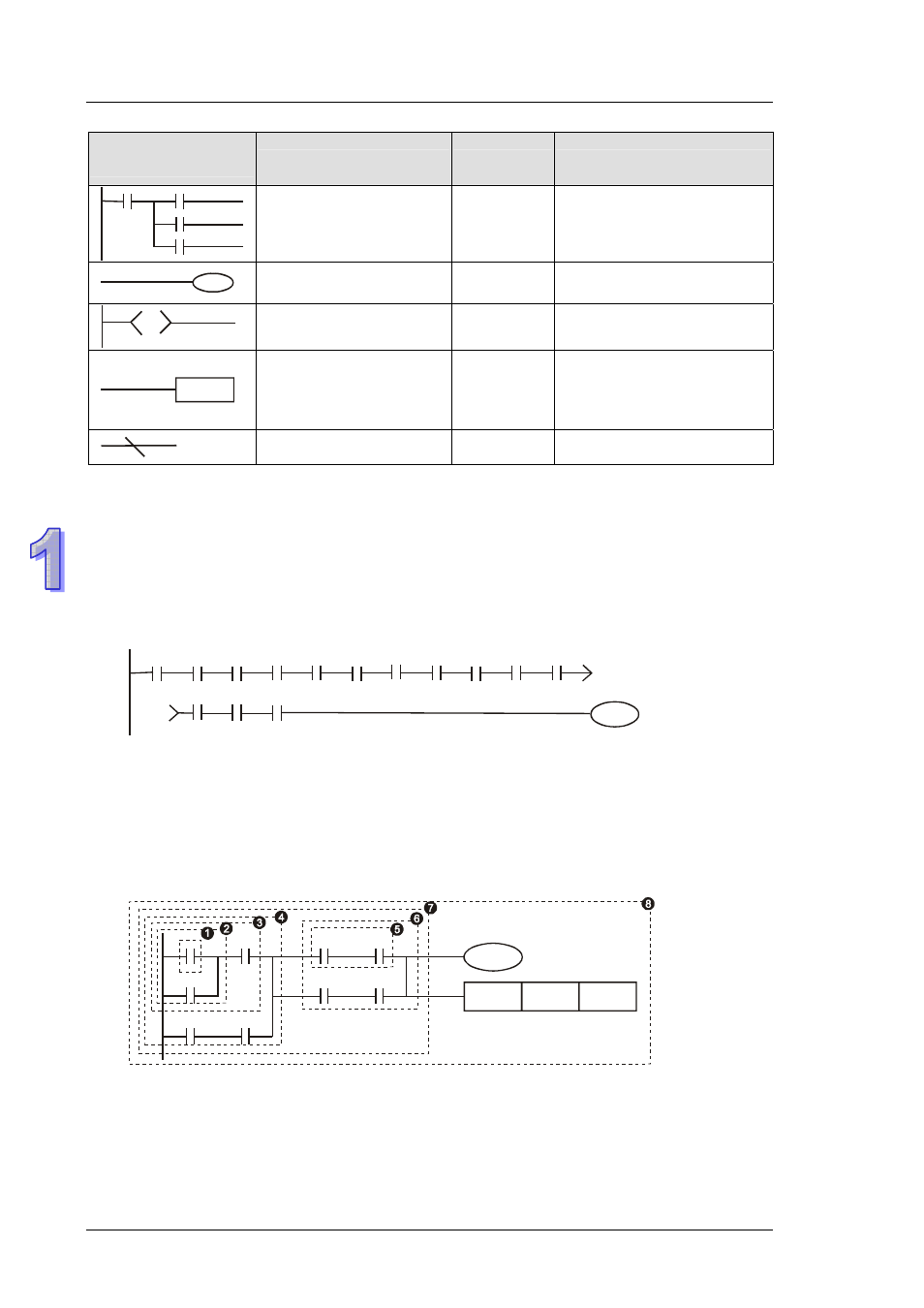

Ladder Diagram

Structure

Explanation

Instruction

Available Devices

Multiple output branches

MPS

MRD

MPP

None

Output coil

OUT

Y, M, S

S

Step ladder

STL S

Basic / Application

instruction

-

Basic instructions and API

instructions. Please refer to

chapter 3 Instruction Set

Inverse logic

INV None

1.5.1 Creating a PLC Ladder Program

The editing of the program should start from the left side bus line to the right side bus line, and from

up to down. However, the right side bus line is omitted when editing in WPLSoft. A single row can

have maximum 11 contacts on it. If more than 11 contacts are connected, a continuous symbol “0”

will be generated automatically and the 12th contact will be placed at the start of next row. The

same input points can be used repeatedly. See the figure below:

Y1

0

0

X0

X1

X2

X3

X4

X5

X6

X7

X10

C0

C1

X11

X12

X13

When evaluating the user program, PLC scan starts from left to right and proceeds to next row

down until the PLC reaches END instruction. Output coils and basic / application instructions

belong to the output process and are placed at the right of ladder diagram. The sample program

below explains the execution order of a ladder diagram. The numbers in the black circles indicate

the execution order.

X0

X1

Y1

X4

M0

X3

M1

T0

M3

Y1

TMR

T0

K10